Azo dye coupling reaction continuous production device and azo dye coupling reaction continuous production method

A coupling reaction, azo dye technology, applied in azo dyes, monoazo dyes, feeding devices and other directions, can solve the problems of low mixing degree of raw materials, low production efficiency, large cooling energy consumption, etc., to avoid decomposition, Avoid material blockage, enhance the effect of mass transfer and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

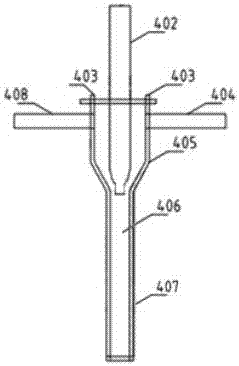

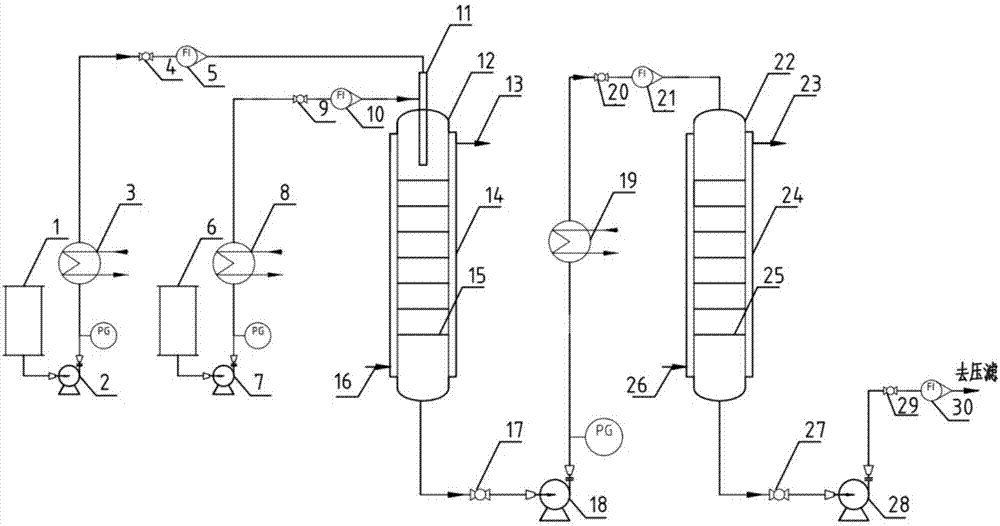

[0035] A continuous production device for coupling reaction of azo dyes is used for production, and the device includes a liquid-liquid jet reactor, a first tower reactor and a second tower reactor;

[0036] The liquid-liquid jet reactor is arranged at the top of the first tower reactor, and the outlet of the mixing chamber is located above the liquid level in the first tower reactor; the suction chamber and the mixing chamber of the liquid-liquid jet reactor The outer sleeve of the injector is provided with an injector jacket; the injector jacket is provided with an inlet and an outlet;

[0037] The working fluid inlet of the liquid-liquid jet reactor is connected to the mixed liquid storage tank, and the sucked fluid inlet of the liquid-liquid jet reactor is connected to the diazo component storage tank;

[0038] Both the first tower reactor and the second tower reactor are provided with a reactor jacket; the lower end of the reaction chamber jacket is provided with an inlet...

Embodiment 2

[0052] The device used in this embodiment 2 and embodiment 1 is only different in that the liquid-liquid jet reactor is provided with 5 sucked fluid inlets, and the ratio of the diameter of the mixing chamber of the liquid-liquid jet reactor to the diameter of the jet pipe nozzle is 6:1, the aperture of the tray hole is 1 / 20 of the diameter of the tray, and the opening ratio is 0.8

[0053] During production, the following steps are included:

[0054] (1) Add 341 kg (1.0 kilomole) of coupling component 1-amino-8-hydroxy-3,6-naphthalene disulfonic acid, 5115 kg of water, and 15 kg of additive sodium carbonate to the mixed liquid storage tank to become a mixed component , adding the prepared p-methoxyaniline diazonium salt containing 1.1 kilomoles to the diazo component storage tank;

[0055] (2) The heat exchange liquid ethanol is input from the inlet provided on the injector jacket and output from the outlet, and the liquid-liquid jet reactor is heat-exchanged, and the temper...

Embodiment 3

[0060] The device used in this embodiment 3 and embodiment 1 is only different in that the liquid-liquid jet reactor is provided with 3 sucked fluid inlets, and the ratio of the diameter of the mixing chamber of the liquid-liquid jet reactor to the diameter of the jet pipe nozzle is 4:1, in the first tower reactor, the aperture of the tray hole is 1 / 30 of the diameter of the tray, and the opening ratio is 0.6, in the second tower reactor, the aperture of the tray hole is 1 / 30 of the diameter of the tray 1 / 25, the opening ratio is 0.7

[0061] During production, the following steps are included:

[0062] (1) Add 341 kg (1.0 kilomole) of coupling component 1-amino-8-hydroxy-3,6-naphthalene disulfonic acid, 5115 kg of water, and 15 kg of additive sodium carbonate to the mixed liquid storage tank to become a mixed component , adding the prepared p-methoxyaniline diazonium salt containing 1.1 kilomoles to the diazo component storage tank;

[0063] (2) Input the heat exchange liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com