Reaction coupling microchannel reactor and application thereof

A technology of microchannel reactor and reaction channel, which is applied in the field of reactors to achieve the effects of improving economy, simple process and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

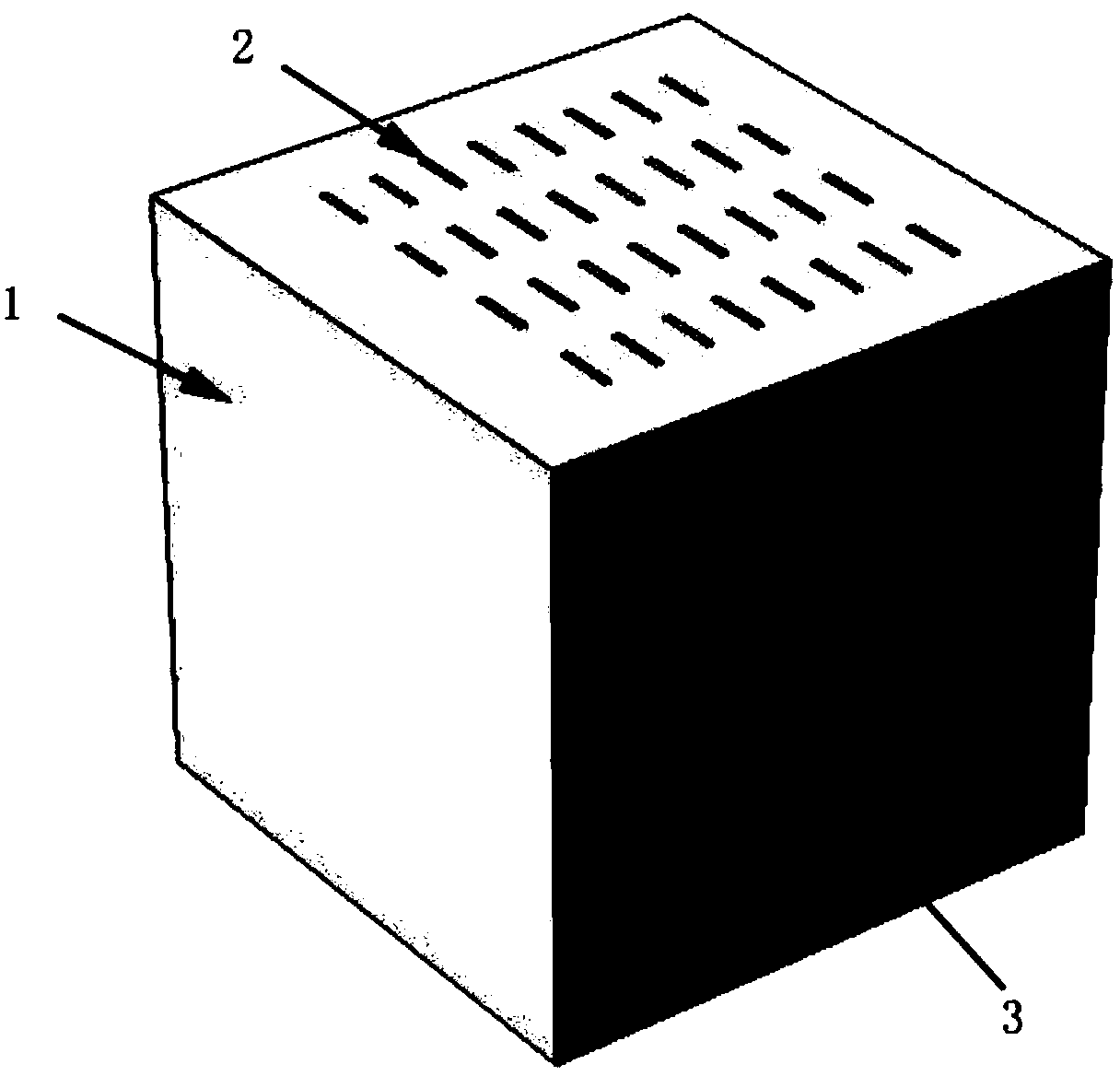

[0049] The channel arrangement of the reaction-coupled microchannel reactor is as follows: figure 1 As shown, the reactor processes a channel plate, an upper cover plate, and a lower cover plate respectively, and the channel plate includes a first reaction channel plate and a second reaction channel plate. The first reaction channel is 100 mm long, 10 mm wide, and 1 mm deep, with a left and right interval of 5 mm. The second reaction channel is 60 mm long, 5 mm wide, and 1 mm deep, with a left and right interval of 5 mm. 1 upper cover plate, 10 first reaction channel plates, 11 second reaction channel plates, and 1 lower cover plate are welded together by diffusion to form an integral reactor. The sum of the area of all channels in a unit volume is 650m 2 / m 3 .

[0050] The cobalt-based Fischer-Tropsch synthesis catalyst (Co / Al 2 o 3 ). The preparation process of the catalyst is as follows: take alumina powder, add distilled water dropwise to incipient wetness, recor...

Embodiment 2

[0055] The channel arrangement of the reaction-coupled microchannel reactor is as follows: figure 1 Shown, reactor structure is identical with embodiment 1.

[0056] Fischer-Tropsch synthesis catalyst is filled in the first reaction channel, and the Fischer-Tropsch synthesis catalyst is Co-Re / Al 2 o 3 catalyst. The preparation process of the catalyst is as follows: 25 grams of cobalt nitrate is dissolved in 50 mL of water to prepare a cobalt nitrate solution; 15 grams of ammonium perrhenate is dissolved in 50 mL of water to prepare an ammonium perrhenate solution. Take alumina powder, then take part of the solution and impregnate alumina to incipient wetness, let it stand for 8 hours, then dry at 120°C for 4 hours, then repeat the above process for multiple impregnations to reach a cobalt content (calculated as oxide) of 25% by weight, The rhenium content is 1% by weight. Calcined at 450° C. for 4 hours in a muffle furnace, the particle size of the obtained catalyst ranges...

Embodiment 3

[0061] The reaction-coupled microchannel reactor and the Fischer-Tropsch synthesis catalyst used in this example are the same as those in Example 2.

[0062]The waste water treatment catalyst is filled in the second reaction channel, and the preparation process of the waste water treatment catalyst is as follows: First, take the commercial Raney Ni catalyst and reduce it in a reaction kettle under a hydrogen atmosphere at 260° C. for 6 hours. After cooling to room temperature, , adding an ethanol solution of tri-n-butyltin acetate to make the Raney Ni catalyst contain 10% by weight of Sn, and then the reaction kettle was kept at 150° C. for 2 hours to obtain a Raney Ni-Sn catalyst.

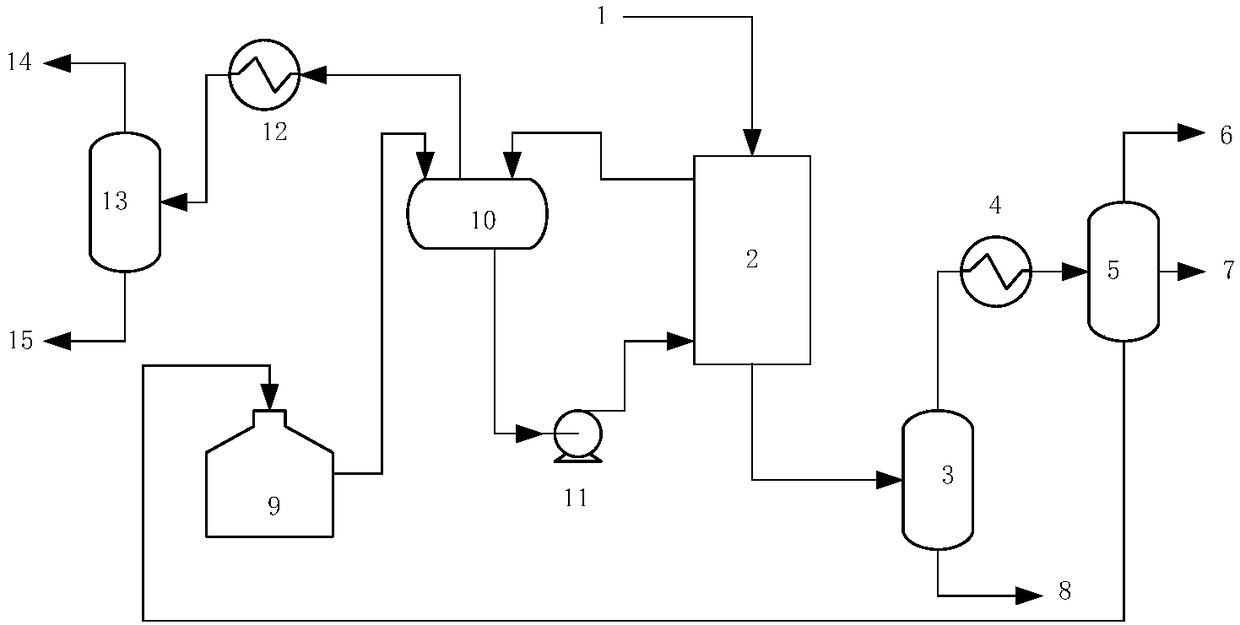

[0063] Attached figure 2 The process of Fischer-Tropsch synthesis reaction and Fischer-Tropsch synthesis wastewater treatment reaction is carried out in a reaction-coupled microchannel reactor. The synthesis gas raw material is fed into the first reaction channel of the reactor, and the hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com