Composite insulation board for exterior wall of building and preparation method thereof

A composite thermal insulation and construction engineering technology, which is applied in the field of composite thermal insulation boards for external walls of construction projects and its preparation, can solve problems such as insufficient stability of composite thermal insulation boards, achieve structural stability, prolong service life, and improve resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

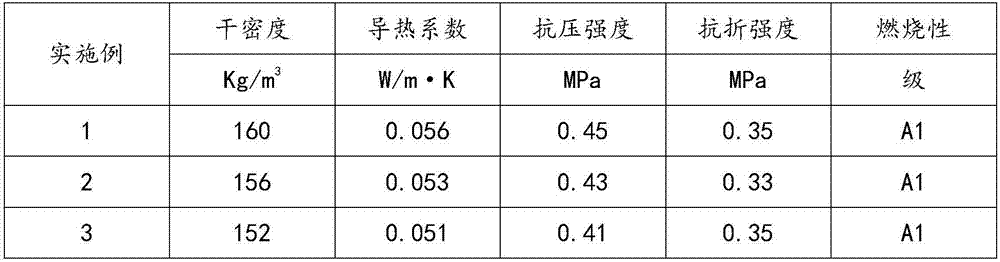

Embodiment 1

[0022] This embodiment provides a composite thermal insulation board for exterior walls of construction projects, which is prepared from the following components in parts by weight: 25 parts of expanded perlite, 20 parts of phenolic resin, 25 parts of pearl sand, 15 parts of inorganic fiber, and 1 part of penetrant 3 parts, water-repellent agent 3 parts, modifier 3 parts, sodium silicate 3 parts, sodium bentonite 2 parts, titanium dioxide 1 part, fly ash 10 parts, gypsum 10 parts, flame retardant 2 parts, stabilizer 2 parts 4 parts, 4 parts of nano polytetrafluoroethylene, 3 parts of trifluoroethyl acrylate, 1 part of hydrogenated nitrile rubber, 0.2 part of cerium sulfate, 15 parts of absolute ethanol, and 120 parts of water. Wherein each part of modifier includes the following components in parts by weight: 15 parts of calcium sulfate, 2 parts of aluminum oxide, 1 part of sodium carboxymethylcellulose, 7 parts of zinc phosphate and 15 parts of iron oxide, and each part of sta...

Embodiment 2

[0024] This embodiment provides a composite insulation board for exterior walls of construction projects, which is prepared from the following components in parts by weight: 35 parts of expanded perlite, 25 parts of phenolic resin, 28 parts of pearl sand, 24 parts of inorganic fiber, and 1 part of penetrant 4 parts, water-repellent agent 4 parts, modifier 4 parts, sodium silicate 4 parts, sodium bentonite 4 parts, titanium dioxide 2 parts, fly ash 12 parts, gypsum 12 parts, flame retardant 2 parts, stabilizer 3 parts 5 parts, 5 parts of nano polytetrafluoroethylene, 3 parts of trifluoroethyl acrylate, 2 parts of hydrogenated nitrile rubber, 0.3 parts of cerium sulfate, 20 parts of absolute ethanol, and 140 parts of water. Wherein each part of modifier includes the following components in parts by weight: 18 parts of calcium sulfate, 3 parts of aluminum oxide, 3 parts of sodium carboxymethylcellulose, 10 parts of zinc phosphate and 20 parts of iron oxide, and each part of stabil...

Embodiment 3

[0026] This embodiment provides a composite thermal insulation board for exterior walls of construction projects, which is prepared from the following components in parts by weight: 40 parts of expanded perlite, 35 parts of phenolic resin, 30 parts of pearlescent sand, 30 parts of inorganic fiber, and 2 parts of penetrating agent 5 parts, water repellent 5 parts, modifier 5 parts, sodium silicate 5 parts, sodium bentonite 6 parts, titanium dioxide 2 parts, fly ash 15 parts, gypsum 15 parts, flame retardant 3 parts, stabilizer 3 parts 5 parts, 5 parts of nano polytetrafluoroethylene, 4 parts of trifluoroethyl acrylate, 2 parts of hydrogenated nitrile rubber, 0.4 parts of cerium sulfate, 25 parts of absolute ethanol, and 160 parts of water. Wherein each part of modifier includes the following components by weight: 20 parts of calcium sulfate, 5 parts of aluminum oxide, 5 parts of sodium carboxymethylcellulose, 12 parts of zinc phosphate and 25 parts of iron oxide, and the stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com