Conductive polymer hydrogel preparation method and application of conductive polymer hydrogel in super capacitor

A conductive polymer and hydrogel technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of reducing the specific surface area, energy density and electron transport capacity of electrode materials, poor cycle stability and processability, and low conductivity of electrode materials, etc., to achieve Excellent cycle stability, excellent rate performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

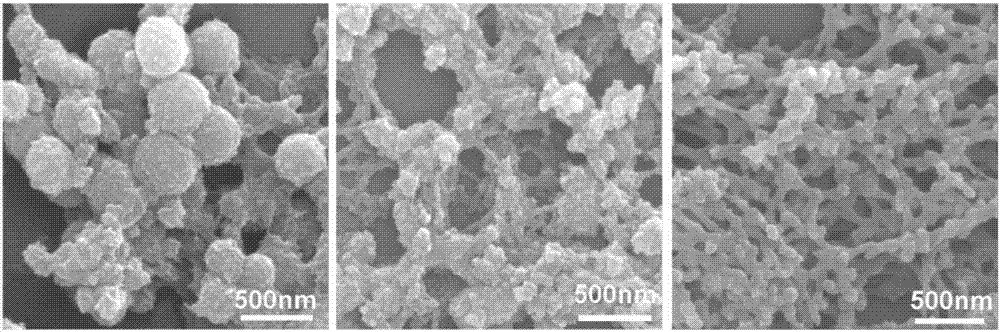

[0034] Weigh 10 mg of sodium alginate and dissolve in 0.5 mL of distilled water. Stir for 1 hour to fully dissolve, then place it in an ice-water bath at 0°C; dissolve 2mmol of EDOT in 0.5mL of ethanol, and then place it in an ice-water bath at 0°C; dissolve 2mmol of ammonium persulfate in 0.5mL of distilled water . Then add the EDOT solution drop by drop into the sodium alginate solution under the condition of stirring. Place it at 4°C for 24-48 hours to form poly(3,4-ethylenedioxythiophene) gel, wash the prepared gel with distilled water and ethanol for 2-3 times; then freeze-dry to obtain the product For SEM testing.

Embodiment 2

[0036] Weigh 10 mg of sodium alginate and dissolve in 0.5 mL of distilled water. Stir for 1 hour to fully dissolve, then place it in an ice-water bath at 0°C; dissolve 2mmol of EDOT in 0.5mL of ethanol, and then place it in an ice-water bath at 0°C; dissolve 4mmol of ammonium persulfate in 0.5mL of distilled water . Then add the EDOT solution drop by drop into the sodium alginate solution under the condition of stirring. Place it at 4°C for 24-48 hours to form poly(3,4-ethylenedioxythiophene) gel, wash the prepared gel with distilled water and ethanol for 2-3 times; then freeze-dry to obtain the product For SEM testing.

Embodiment 3

[0038] Weigh 10 mg of sodium alginate and dissolve in 0.5 mL of distilled water. Stir for 60 minutes to fully dissolve it, and then place it in an ice-water bath at 0°C; dissolve 1.5mmol of EDOT in 0.5mL of ethanol, and then place it in an ice-water bath at 0°C; dissolve 4mmol of ammonium persulfate in 0.5mL of distilled water. Then add the EDOT solution drop by drop into the sodium alginate solution under the condition of stirring. Place it at 4°C for 24-48 hours to form poly(3,4-ethylenedioxythiophene) gel, wash the prepared gel with distilled water and ethanol for 2-3 times; then freeze-dry to obtain the product For SEM testing.

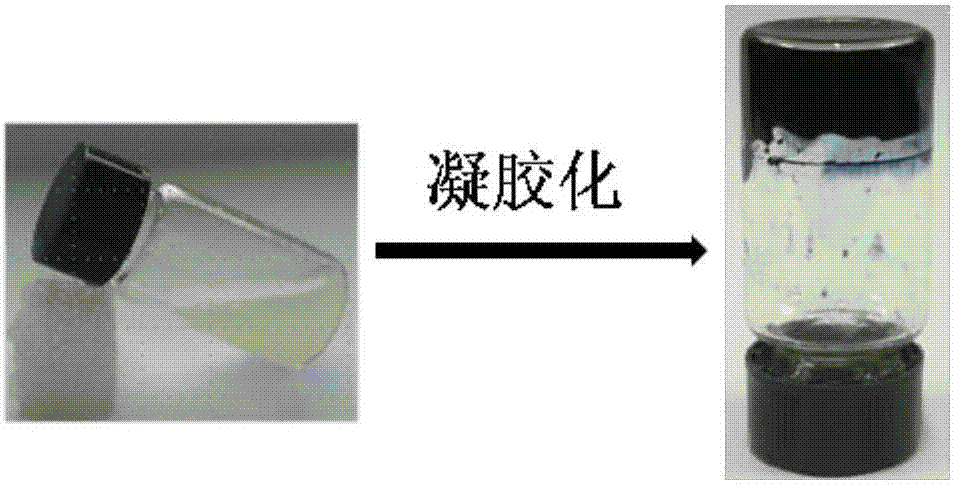

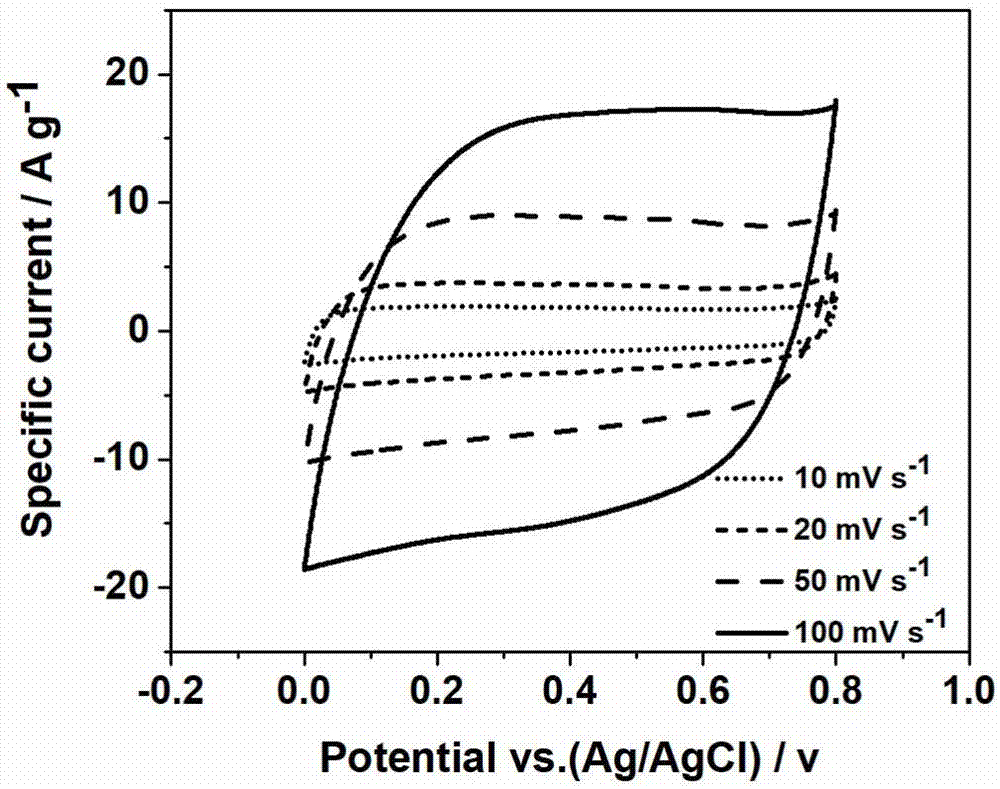

[0039] figure 1 It is a digital photo of poly(3,4-ethylenedioxythiophene) before and after gelation. During the process from solution to gel, the color changes obviously, from white-yellow-green-dark green-black. figure 2 SEM of poly(3,4-ethylenedioxythiophene) gels prepared for different ratios of EDOT and ammonium persulfate. Ethylenedioxyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com