Clean vacuum pump oil

A vacuum pump oil, clean technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of difficulty in ensuring high vacuum, poor thermal stability and oxidation stability, prolonging pump life, etc. performance, the effect of keeping the interior clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

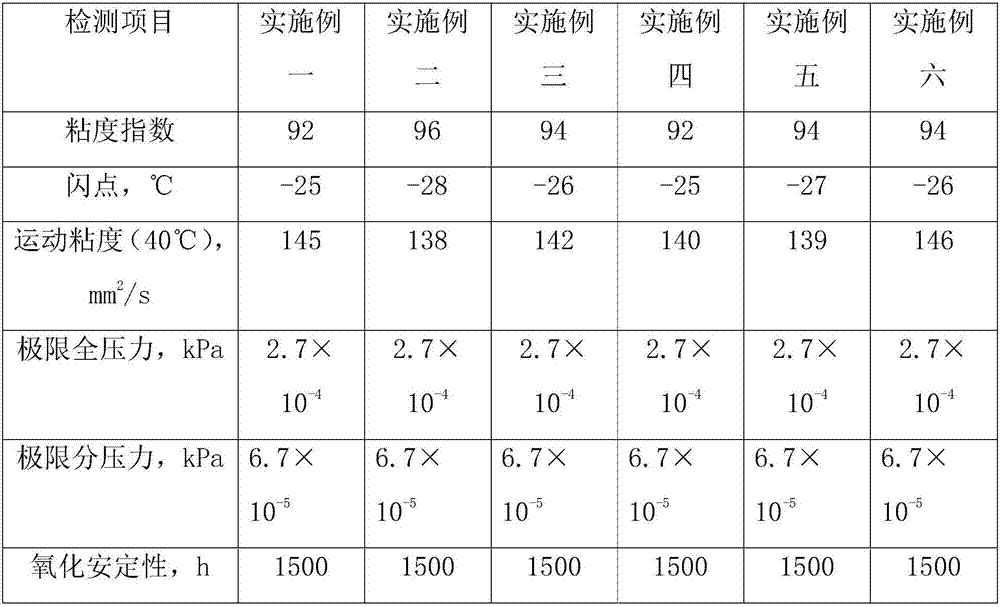

Examples

preparation example Construction

[0024] In the present embodiment, the preparation method of the vacuum pump oil comprises the following steps:

[0025] Mix oil-soluble polyether, trimellitate and alkyl diphenyl ether, stir slowly and raise the temperature to 120°C at a rate of 6-8°C / min, then continue stirring at a rate of 3-5°C / min Cool down to 80°C, add anti-emulsion agent, air compressor oil compounding agent, antioxidant and defoamer, and stir for at least 40 minutes. It can also promote the mutual synergy of various raw material components, better exert the performance advantages, and prepare vacuum pump oil with excellent performance and in line with actual needs.

[0026] In this example, all raw material components can be obtained through market purchase.

Embodiment 1

[0029] The cleaning type vacuum pump oil provided by this embodiment, the raw materials of the vacuum pump oil include the following components by weight percentage: oil-soluble polyether 15%, trimellitate 74%, alkyl diphenyl ether 5%, anti-emulsion agent 2 %, air compressor oil compounding agent 1.98%, antioxidant 2%, defoamer 0.02%;

[0030] in:

[0031] The kinematic viscosity of the oil-soluble polyether at 40°C is 50mm 2 / s;

[0032] The kinematic viscosity of the trimellitate at 40°C is 65mm 2 / s;

[0033] The alkyl diphenyl ether is dodecyl diphenyl ether;

[0034] The model of the air compressor oil compounding agent is T6023;

[0035] The anti-emulsion agent is a derivative of polyoxypropylene type;

[0036] The antioxidant is p-phenylenediamine, and the defoamer is simethicone.

[0037] In the present embodiment, the preparation method of the vacuum pump oil comprises the following steps:

[0038] Mix oil-soluble polyether, trimellitate and alkyl diphenyl eth...

Embodiment 2

[0040] The cleaning type vacuum pump oil provided in this embodiment, the raw materials of the vacuum pump oil include the following components by weight percentage: 20% oil-soluble polyether, 68% trimellitate, 8% alkyl diphenyl ether, anti-emulsion agent 1 %, air compressor oil compounding agent 1.5%, antioxidant 1.48%, defoamer 0.02%;

[0041] in:

[0042] The kinematic viscosity of the oil-soluble polyether at 40°C is 50mm 2 / s;

[0043] The kinematic viscosity of the trimellitate at 40°C is 75mm 2 / s;

[0044] The alkyl diphenyl ether is dodecyl diphenyl ether;

[0045] The model of the air compressor oil compounding agent is T6023;

[0046] The anti-emulsion agent is a derivative of polyoxypropylene type;

[0047] The antioxidant is p-phenylenediamine, and the defoamer is simethicone.

[0048] In the present embodiment, the preparation method of the vacuum pump oil comprises the following steps:

[0049] Mix oil-soluble polyether, trimellitate and alkyl diphenyl e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com