Amorphous magnetic powder core precursor particle, amorphous magnetic powder core and preparation method thereof

A magnetic powder core and precursor technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of amorphous magnetic powder core magnetic permeability and saturation magnetic induction intensity reduction, unfavorable miniaturization of electronic components, etc., to improve Magnetic permeability, high magnetic permeability, and the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The present invention further provides a method for preparing the amorphous magnetic powder core, comprising:

[0036] S1, providing the amorphous alloy particles;

[0037] S2, coating the amorphous alloy particles with the nano soft magnetic ferrite powder and a binder to obtain the amorphous magnetic powder core precursor particles;

[0038] S3, pressing and molding the amorphous magnetic powder core precursor particles to obtain a shaped amorphous magnetic powder core precursor;

[0039] S4, performing a stress relief annealing treatment on the shaped amorphous magnetic powder core precursor to obtain the amorphous magnetic powder core.

[0040] In step S1, the amorphous alloy particles can be obtained by crushing amorphous strips, water atomization or gas atomization.

[0041] In step S2, the nano soft magnetic ferrite powder and binder are mixed and coated on the surface of the amorphous alloy particles. The amorphous alloy particles can be coated by a dispersion...

Embodiment 1

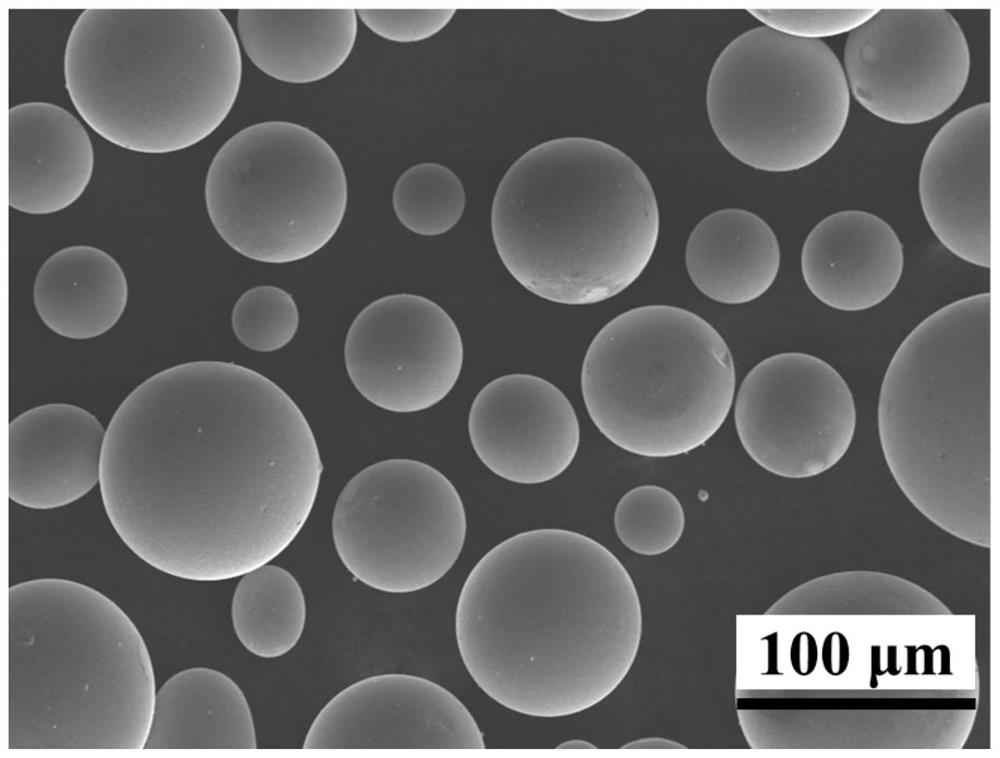

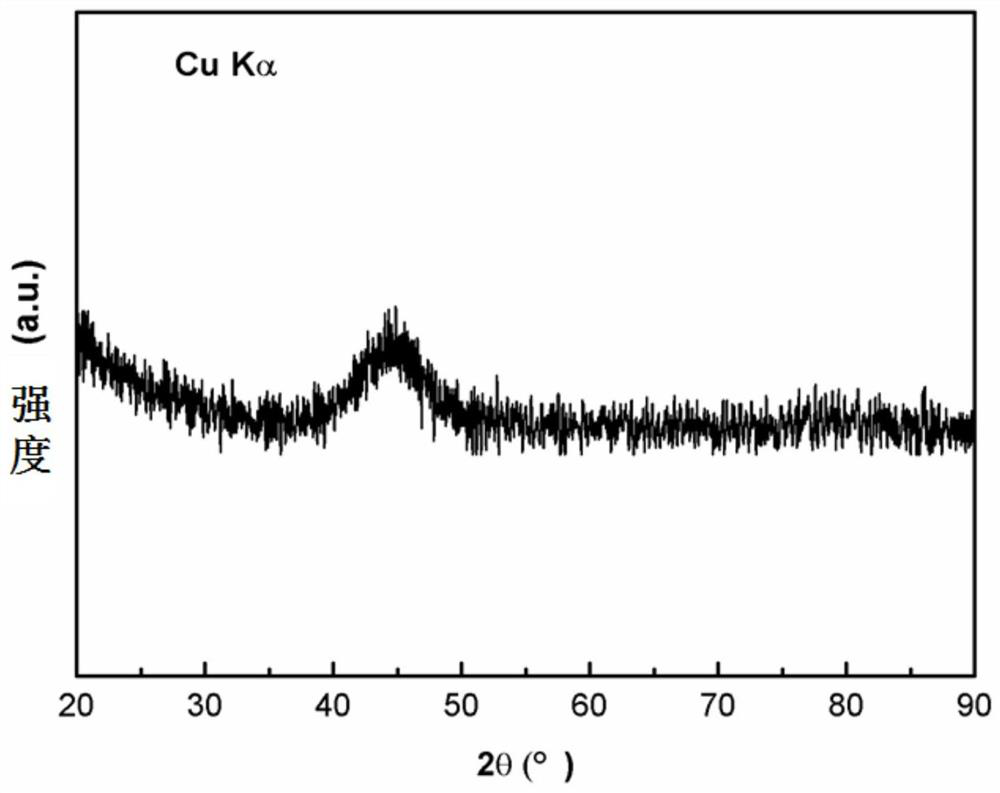

[0053] Select the Fe prepared by gas atomization method 76 Si 9 B 10 P 5 Amorphous alloy particles, with a 200-mesh sieve for Fe 76 Si 9 B 10 P 5 The amorphous alloy particles were sieved, and the Fe 76 Si 9 B 10 P 5 The morphology of amorphous alloy particles was analyzed, such as figure 1 As shown, it can be seen that Fe 76 Si 9 B 10 P 5 Amorphous alloy particles present a spherical shape with a smooth surface and no obvious defects such as holes and holes; the structure is detected by X-ray diffractometer (XRD), and the results are as follows: figure 2 As shown, it can be seen that there is no diffraction peak corresponding to any crystal on the XRD spectrum, only a broad diffuse scattering peak, indicating that the Fe used 76 Si 9 B 10 P 5 Amorphous alloy particles are completely amorphous.

[0054] to Fe 76 Si 9 B 10 P 5 The amorphous alloy particles are subjected to insulation coating treatment, and 1% of nano-nickel-zinc soft magnetic ferrite pow...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, except that the mass percentage of the nano-nickel-zinc soft ferrite powder is 2%.

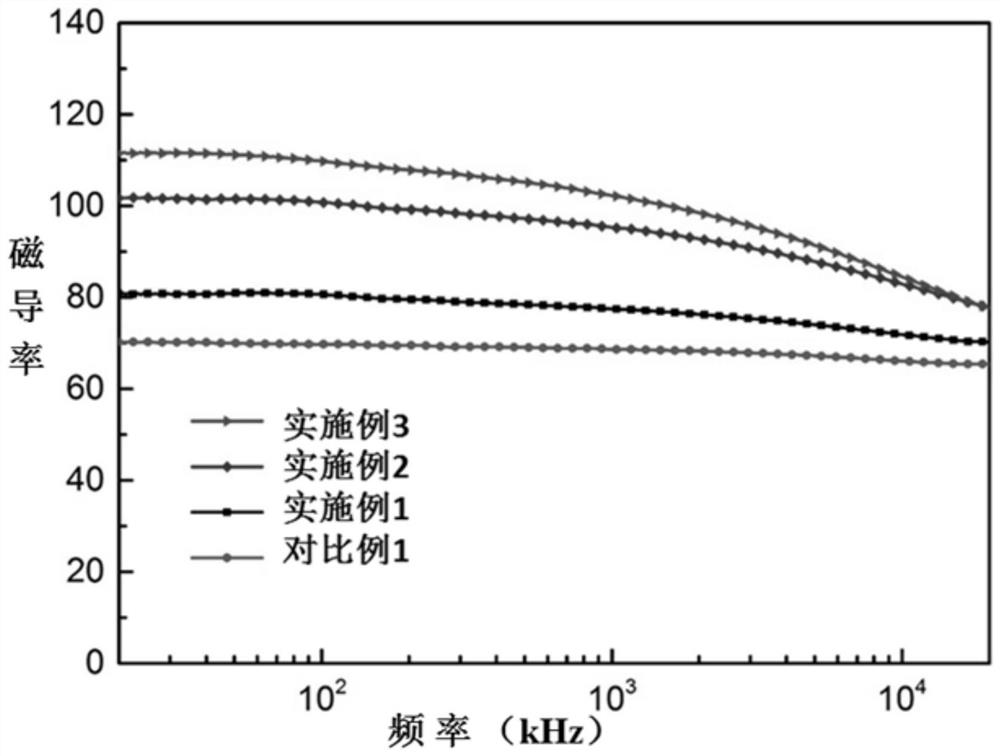

[0060] After testing, the magnetic permeability of the amorphous magnetic powder core at a frequency of 100kHz is 102, and at the same time, the frequency stability is excellent, such as image 3 Shown; the loss of magnetic powder core is very low, under the condition of 50kHz, 0.1T, the loss is 711mW / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com