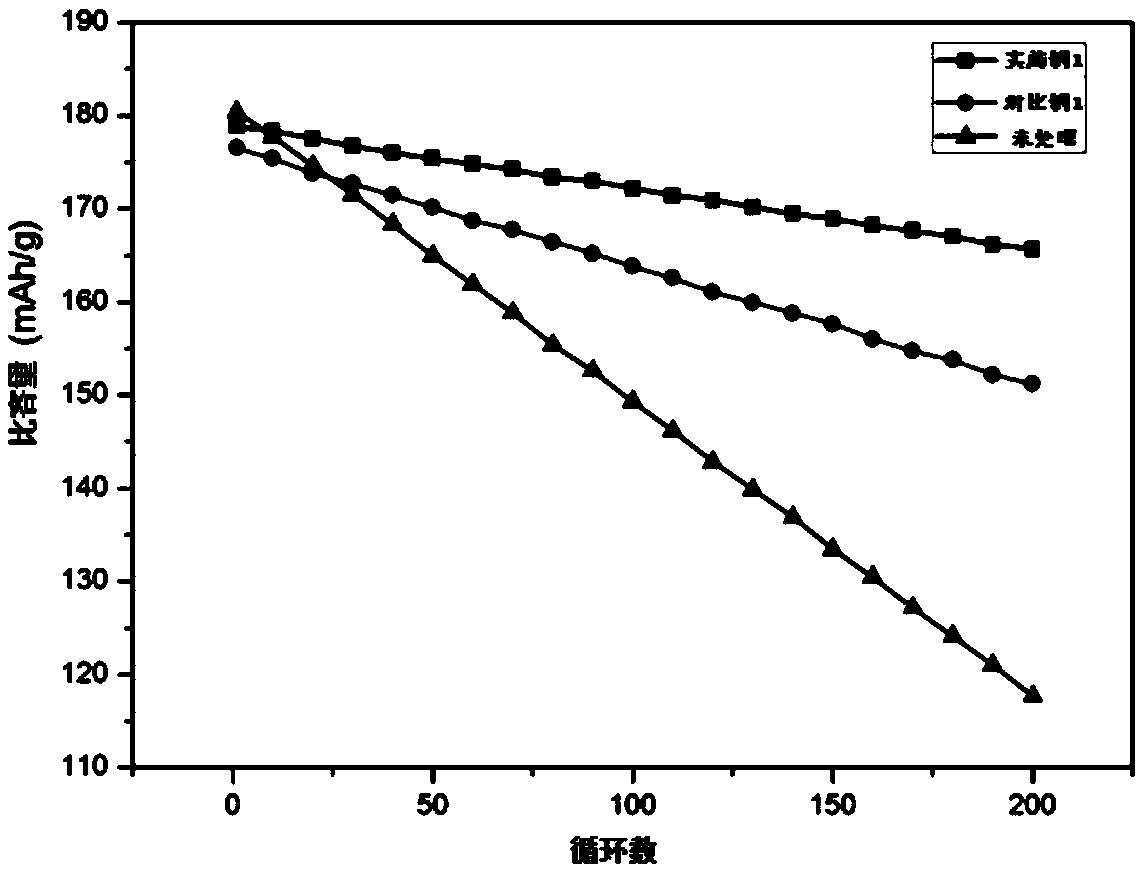

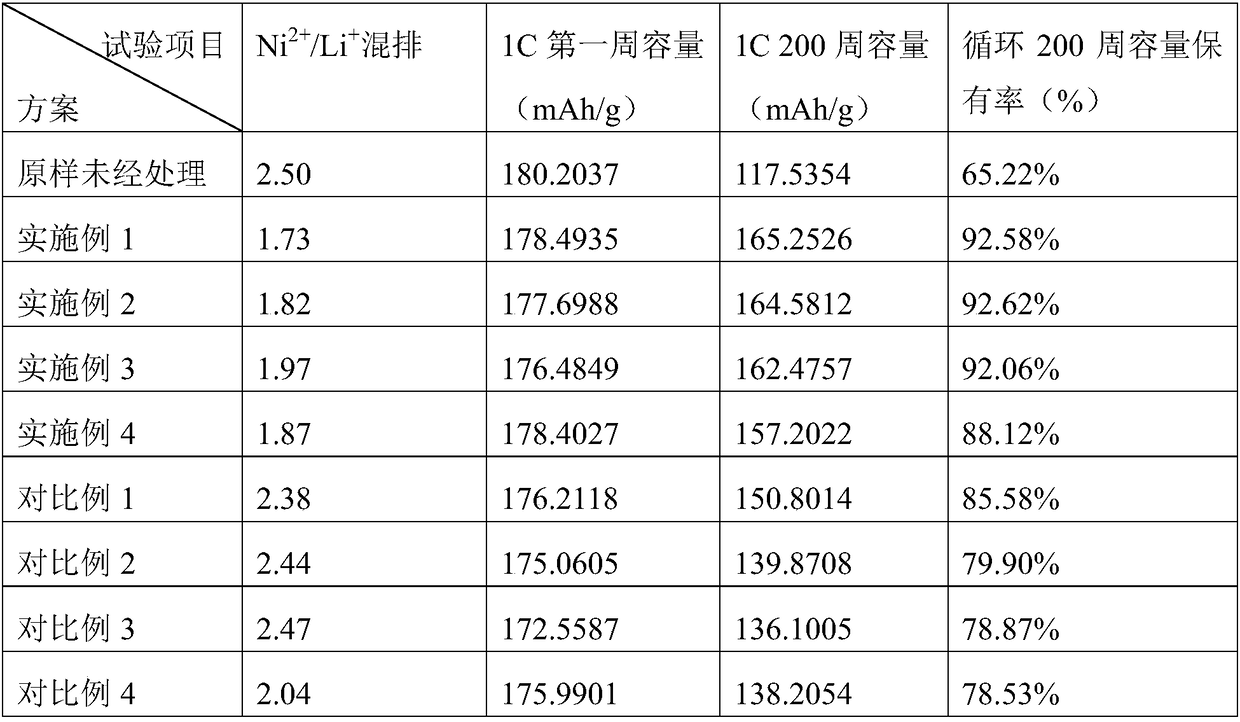

A method for improving the cycle performance of high-nickel cathode materials

A cathode material and cycle performance technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as poor cycle performance of high-nickel cathode materials, reduce Ni2+/Li+ mixed discharge, improve structural stability, The effect of stabilizing cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 1L of deionized water at 50°C in a 2L beaker in a water bath at 50°C, add lithium acetate into the deionized water while stirring until saturated, solids precipitate out, and filter to obtain a saturated lithium acetate solution at 50°C.

[0024] Take 800mL of the above-mentioned saturated lithium acetate solution at 50°C in a 2L beaker, add 400g of high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 and 2 g of manganese acetate tetrahydrate, and stirred for 10 min, the filter cake after solid-liquid separation was dried in a vacuum oven at 120° C., then cooled and pulverized. The dry powder obtained after pulverization was kept at 680° C. for 8 hours, and then cooled at room temperature to obtain the final high-nickel positive electrode material.

Embodiment 2

[0026] Put 1L of deionized water at 50°C in a 2L beaker in a water bath at 50°C, add lithium tartrate into the deionized water while stirring until saturated, solids precipitate out, and filter to obtain a saturated lithium tartrate solution at 50°C.

[0027] Take 800mL of the above-mentioned saturated lithium tartrate solution at 50°C in a 2L beaker, add 400g of high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 and 2 g of manganese acetate tetrahydrate, and stirred for 20 minutes, the filter cake after solid-liquid separation was dried in a vacuum oven at 120° C., then cooled and pulverized. The dry powder obtained after pulverization was kept at 690° C. for 8 hours, and then cooled at room temperature to obtain the final high-nickel cathode material.

Embodiment 3

[0029] Put 1L of 50°C deionized water into a 2L beaker in a 50°C water bath, add lithium gluconate into the deionized water until saturated and solids precipitate out while stirring, and filter to obtain a saturated solution of lithium gluconate at 50°C.

[0030] Take 800mL of the above-mentioned saturated lithium gluconate solution at 50°C in a 2L beaker, add 400g of high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 and 2 g of manganese acetate tetrahydrate, and stirred for 30 minutes, the filter cake after solid-liquid separation was dried in a vacuum oven at 120° C., then cooled and pulverized. The dry powder obtained after pulverization was kept at 700° C. for 8 hours, and then cooled at room temperature to obtain the final high-nickel cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com