A co-doped modified high-nickel ternary material and its preparation method

A technology of positive electrode materials and metal elements, applied in the field of lithium battery positive electrode materials and preparation, can solve the problems of complicated manufacturing process, high cost, unfavorable industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1g high nickel (Ni 0.6 co 0.2 mn 0.2 )CO 3 The powder was successively mixed with 0.37674g lithium carbonate (Li 2 CO 3 ), 0.01768g boric acid (H 3 BO 3 ) and 0.02261g lithium carbonate (Li 2 CO 3 ) mixed evenly, and then raised to 500°C at a rate of 5°C / min in an oxygen atmosphere, and kept for 5 hours; then raised to 880°C at a rate of 3°C / min, kept for 15 hours, and naturally cooled to room temperature to obtain a co-doped modified High nickel ternary material.

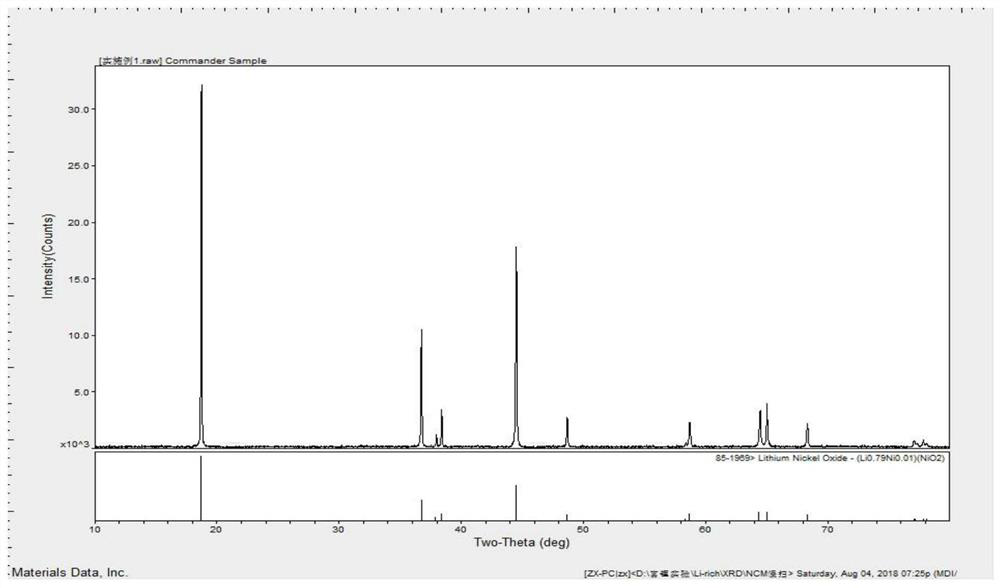

[0024] The chemical general formula of the high-nickel ternary material prepared by the above method is LiNi 0.6 co 0.2 mn 0.2 Li 0.11 B 0.017 o 1.96 . The crystal structure of the co-doped modified high-nickel ternary material was analyzed using powder X-ray diffractometer (XRD), the results are as follows figure 1 As shown, the position of the peaks in the figure corresponds to the standard PDF card. There is the strongest peak at 18.726°, which is the (003) peak, the second strongest peak ...

Embodiment 2

[0031] 1g high nickel (Ni 0.6 co 0.2 mn 0.2 )O2 The powder was successively mixed with 0.49397g lithium carbonate (Li 2 CO 3 ), 0.02318g boric acid (H 3 BO 3 ) and 0.04446g lithium carbonate (Li 2 CO 3 ) were mixed evenly, and then the temperature was raised to 880° C. at a rate of 3° C. / min under an oxygen atmosphere, kept for 15 hours, and naturally cooled to room temperature to obtain a co-doped modified high-nickel ternary material.

[0032] The chemical general formula of the high-nickel ternary material prepared by the above method is LiNi 0.6 co 0.2 mn 0.2 Li 0.13 B 0.018 o 1.95 . The crystal structure of the co-doped modified high-nickel ternary material was analyzed by powder X-ray diffractometer (XRD). The position of the peak in the figure corresponds to the standard PDF card, and there is the strongest peak at 18.747°, which is (003) There is a second strong peak at 44.530°, which is the (104) peak, and a third strong peak at 36.768°, which is the (10...

Embodiment 3

[0036] 1g high nickel (Ni 0.8 co 0.1 mn 0.1 )CO 3 Powder, successively mixed with 0.5870g lithium hydroxide (LiOH·OH), 0.04970g sodium orthophosphate (Na 3 PO 4 ) and 0.02769g sodium carbonate (Na 2 CO 3 ) mixed evenly, and then raised to 500°C at a rate of 5°C / min in an oxygen atmosphere, and kept for 3 hours; then raised to 780°C at a rate of 10°C / min, kept for 15 hours, and naturally cooled to room temperature to obtain a co-doped modified High nickel ternary material.

[0037] The chemical general formula of the high-nickel ternary material prepared by the above method is LiNi 0.8 co 0.1 mn 0.1 Na 0.11 P 0.026 o 2.015 . The crystal structure of the co-doped modified high-nickel ternary material was analyzed by powder X-ray diffractometer (XRD). The position of the peak in the figure corresponds to the standard PDF card, and there is the strongest peak at 18.732°, which is (003) Peak, there is a second strong peak at 44.489°, which is the (104) peak, and there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com