A kind of high crystallinity lithium ion battery cathode material synthesis method and cathode material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of high-crystallinity lithium-ion battery positive electrode material synthesis methods and positive electrode materials, can solve problems such as difficult synthesis, electrochemical performance degradation, and difficulty in obtaining, and achieve excellent high-temperature storage and cycle performance Excellent, well-developed crystal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

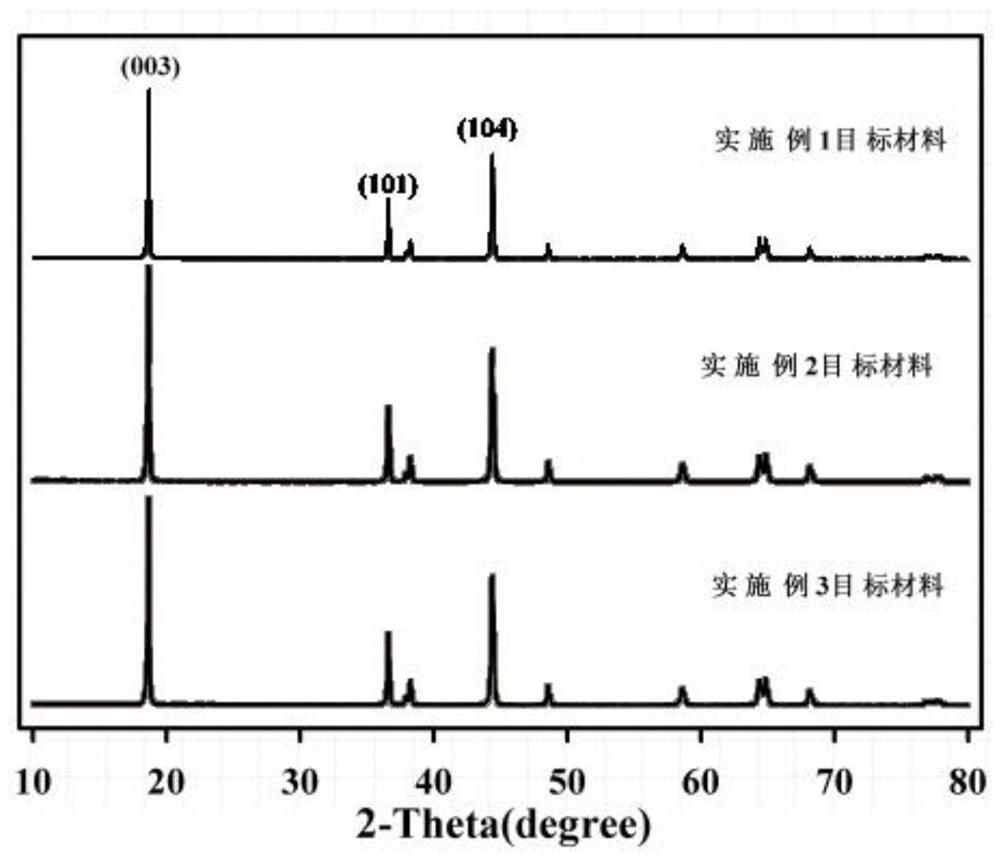

[0030] Weigh the precursor Ni according to the molar ratio of Li:(Ni+Co+Mn)=0.9 0.6 co 0.2 mn 0.2 (OH) 2 and lithium carbonate, then add 0.1% Al 2 o 3 Place in a high-speed mixer, first mix at a low speed of 500r / min for 10min, then mix at a high speed of 1000r / min for 30min; place the uniformly mixed material in a sintering furnace under an oxygen atmosphere for sintering at 885°C for 12h to obtain a positive electrode material matrix;

[0031] Weigh the above-mentioned cathode material matrix and lithium hydroxide according to the molar ratio of Li:(Ni+Co+Mn)=0.16, then add 0.1% rutile TiO 2 Place in a high-speed mixer, first mix at a low speed of 300r / min for 10min, then mix at a high speed of 800r / min for 25min; place the uniformly mixed material in a sintering furnace under an air atmosphere for sintering at 750°C for 8h to obtain Al-doped Ti Coated cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 ;

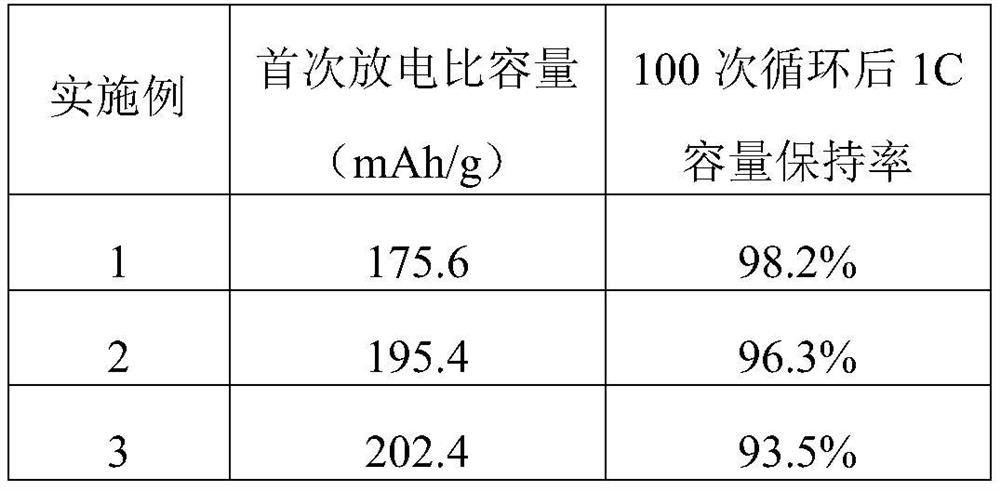

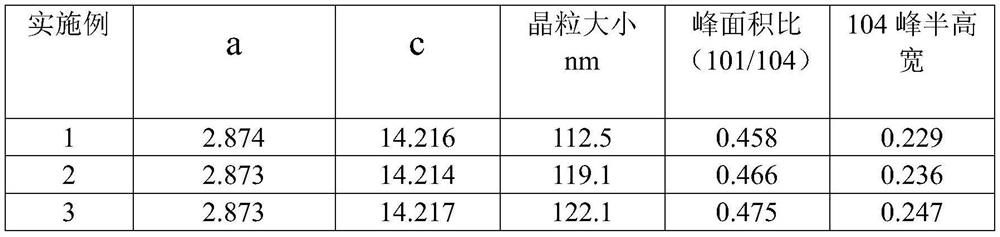

[0032]The 0.1C discharge specific capacity of the target positive ...

Embodiment 2

[0034] Weigh the precursor Ni according to the molar ratio of Li:(Ni+Co+Mn)=0.86 0.8 co 0.1 mn 0.1 (OH) 2 and lithium carbonate, then add 0.1% Al 2 o 3 Place in a high-speed mixer, first mix at a low speed of 500r / min for 10min, then mix at a high speed of 1000r / min for 30min; place the uniformly mixed material in a sintering furnace under an oxygen atmosphere for sintering at 770°C for 10h to obtain a positive electrode material matrix;

[0035] Weigh the above positive electrode material substrate and lithium hydroxide according to the molar ratio of Li:(Ni+Co+Mn)=0.17, then add 0.1% SiO 2 Place in a high-speed mixer, first mix at a low speed of 300r / min for 10min, then mix at a high speed of 800r / min for 25min; place the uniformly mixed material in a sintering furnace at 650°C for 10h under an air atmosphere to obtain Al-doped Si Coated cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 ;

[0036] The 0.1C discharge specific capacity of the target positive electrode mate...

Embodiment 3

[0038] Weigh the precursor Ni according to the molar ratio of Li:(Ni+Co+Mn)=0.75 0.85 co 0.1 al 0.05 (OH) 2 and lithium carbonate, then add 0.1% Al 2 o 3 Place in a high-speed mixer, first mix at a low speed of 500r / min for 10min, and then mix at a high speed of 1000r / min for 30min; place the uniformly mixed material in a sintering furnace under an oxygen atmosphere for sintering at 770°C for 8h to obtain a positive electrode material matrix;

[0039] Weigh the above-mentioned cathode material substrate and lithium hydroxide according to the molar ratio of Li:(Ni+Co+Mn)=0.27, then add 0.1% B 2 o 3 Place in a high-speed mixer, first mix at a low speed of 300r / min for 10min, then mix at a high speed of 800r / min for 25min; place the uniformly mixed material in a sintering furnace at 650°C for 12h in an air atmosphere to obtain Al-doped B Coated cathode material LiNi 0.85 co 0.1 al 0.05 o 2 ;

[0040] The 0.1C discharge specific capacity of the target positive electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com