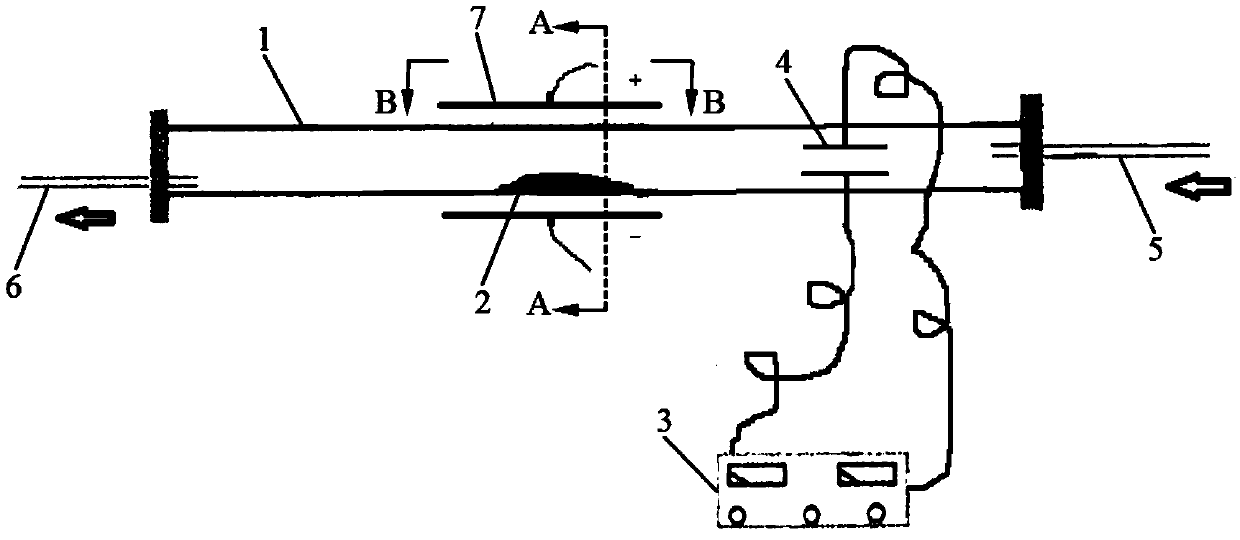

Electromagnetic field-confined plasma enhanced oxidation roasting method for high-nickel cathode material of lithium-ion battery

A lithium-ion battery and cathode material technology, applied in the field of energy material preparation, can solve the problems of high degree of cation mixing, limited enhanced oxidation, and low utilization rate of active oxygen, so as to improve oxidation capacity and oxidation speed, and improve labor efficiency. Conditions, the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

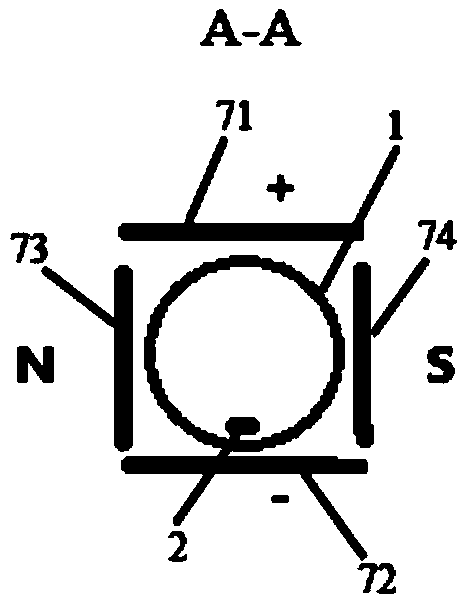

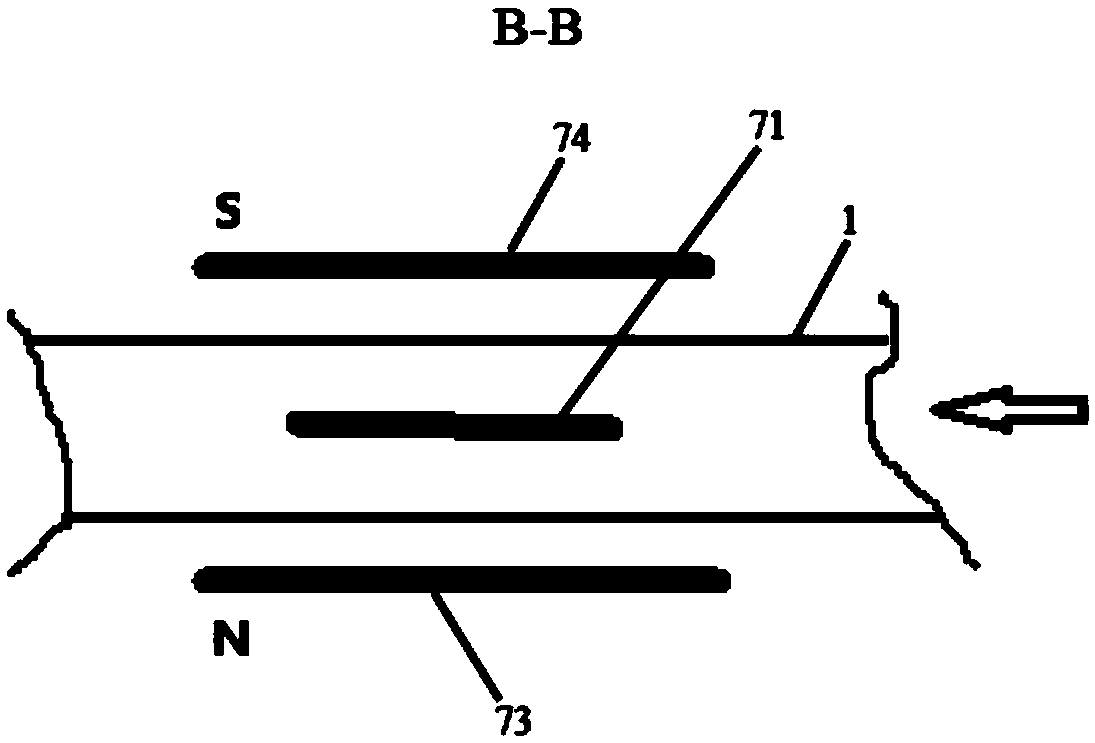

Method used

Image

Examples

Embodiment 1

[0077] Weigh 0.1mol precursor Ni 0.80 co 0.15 Al 0.05 (OH) 2 and 0.0525mol lithium carbonate, the precursor and lithium carbonate powder are uniformly mixed, placed in a quartz tube (placed in a quartz tube furnace). Air is introduced into the quartz tube furnace at a flow rate of 500ml / min, and the reacted gas is discharged out of the quartz tube furnace, and the gas pressure in the furnace is maintained at normal pressure. Using an AC power supply, adjust the voltage of the atmospheric pressure discharge plasma generator to 10kV, the frequency to 15kHZ, and the power to 500W, so that plasma discharge occurs in the air in the tube to generate active oxygen. Adjust the electric field intensity generated by the deflection electric field generator to 5kV / m, and adjust the magnetic induction intensity generated by the magnet to 2T. The quartz tube furnace was raised to 800°C at a heating rate of 200°C / h, kept for 12h and then cooled to room temperature naturally. The reactiv...

Embodiment 2

[0082] Turn off the deflection electric field generator, and other conditions are the same as in Example 1, and synthesize nickel-cobalt lithium aluminate, a high-nickel positive electrode material. The cation mixing degree in the nickel-cobalt lithium aluminate cathode material is measured to be about 2.5%, the pH is 11.58, the first Coulombic efficiency (0.1C) of the coin half-cell is 88.8%; the 0.1C gram specific capacity of the coin-type half-cell is 201mAh / g; The 1C gram specific capacity of the aluminum shell full battery is 165mAh / g, the 300-cycle capacity retention rate is 92.6%, and the 500-cycle capacity retention rate is 89.5%.

[0083] The overall performance of the material is lower than that of Example 1, which shows that light has magnetic field confinement but not electric field confinement, and the confinement and enrichment effect of plasma is weakened, which affects the enhanced oxidation roasting effect.

Embodiment 3

[0085] Turn off the electromagnet, and other conditions are the same as in Example 1, and synthesize nickel-cobalt lithium aluminate, a high-nickel positive electrode material. It is measured that the cation mixing degree in the nickel-cobalt lithium aluminate positive electrode material is about 2.4%, the pH is 11.60, the first coulombic efficiency (0.1C) of the coin half-cell is 89.8%; the 0.1C gram specific capacity of the coin-type half-cell is 201mAh / g; The 1C gram specific capacity of the aluminum case full battery is 166mAh / g, the 300-cycle cycle capacity retention rate is 92.7%, and the 500-cycle cycle capacity retention rate is 90.5%.

[0086] The comprehensive performance of the material is lower than that of Example 1, which shows that there is only electric field confinement but no magnetic field confinement, and the confinement and enrichment effect of plasma will also be weakened, which affects the enhanced oxidation roasting effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com