Mineral beneficiation method for separating bismuth and sulfide from bismuth-sulfide concentrate

A beneficiation method and technology of sulfur concentrate, which is applied in the field of separation of bismuth and sulfur in bismuth-sulfur concentrate, can solve the problems of difficulty in obtaining bismuth concentrate, large difference in floatability of pyrrhotite, difficulty in separation of bismuth-sulfur flotation, etc. problems, to achieve the effects of reducing impact, efficient recovery, and reducing the amount of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

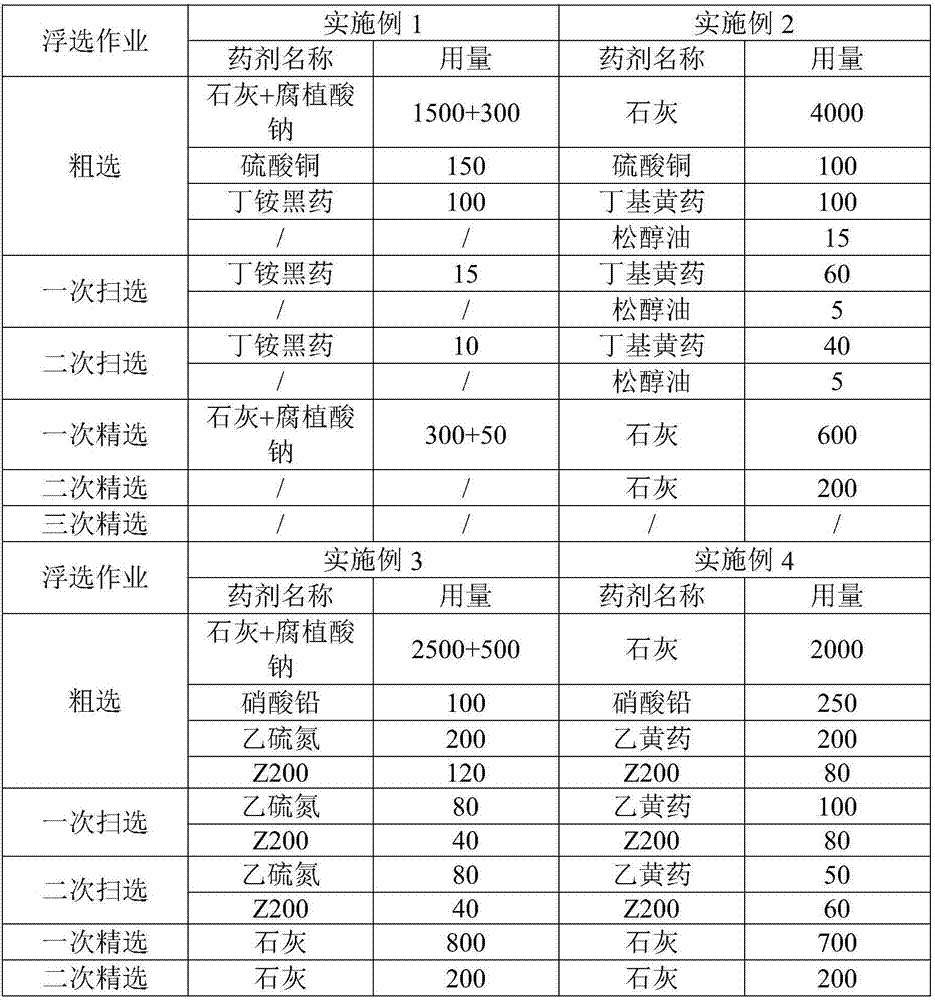

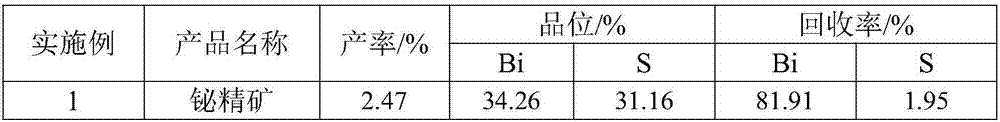

Embodiment 1

[0045] Example 1 The ore in this example is bismuth-sulfur concentrate in a place in Yunnan, China.

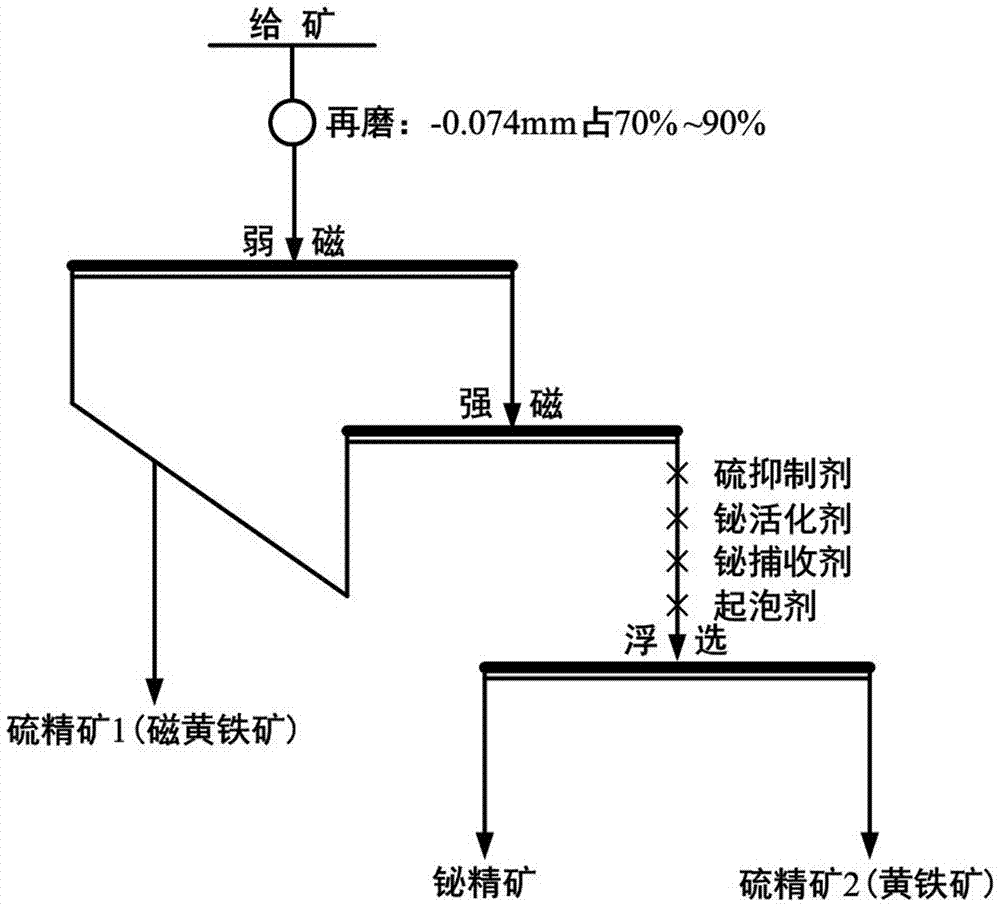

[0046] S1. Bismuth sulfur concentrate is ground to -0.074mm, accounting for 80%;

[0047] S2. Carry out weak magnetic separation of the product after grinding in a weak magnetic separator, adjust the magnetic field strength to 0.3T, and obtain pyrrhotite concentrate and weak magnetic tailings with stronger magnetism;

[0048] S3. Feed the weak magnetic tailings into the strong magnetic separator for strong magnetic roughing, adjust the magnetic field strength to 0.6T, and obtain the weaker magnetic pyrrhotite coarse concentrate and strong magnetic tailings;

[0049] S4. Feed the pyrrhotite coarse concentrate into the strong magnetic separator for strong magnetic concentration, adjust the magnetic field strength to 0.5T, and obtain the weaker magnetic pyrrhotite concentrate and magnetic middle ore;

[0050] S5. Merging the pyrrhotite concentrate with stronger magnetism and the...

Embodiment 2

[0053] In Example 2, the ore is a bismuth-sulfur concentrate in a place in Jiangxi, China.

[0054] S1. Bismuth sulfur concentrate is ground to -0.074mm, accounting for 85%;

[0055] S2. Carry out weak magnetic separation to the product after grinding in a weak magnetic separator, and adjust the magnetic field strength to 0.15T to obtain pyrrhotite concentrate and weak magnetic tailings with stronger magnetism;

[0056] S3. Feed the weak magnetic tailings into the strong magnetic separator for strong magnetic roughing, adjust the magnetic field strength to 0.8T, and obtain the weaker magnetic pyrrhotite coarse concentrate and strong magnetic tailings;

[0057] S4. Feed the pyrrhotite coarse concentrate into the strong magnetic separator for strong magnetic concentration, adjust the magnetic field strength to 0.7T, and obtain the weaker magnetic pyrrhotite concentrate and magnetic middle ore;

[0058] S5. Merging the pyrrhotite concentrate with stronger magnetism and the pyrrh...

Embodiment 3

[0061] Example 3 The ore in this example is bismuth-sulfur concentrate in a certain place in Guangxi, China.

[0062] S1. Bismuth sulfur concentrate is ground to -0.074mm, accounting for 76%;

[0063] S2. Carry out weak magnetic separation of the product after grinding in a weak magnetic separator, adjust the magnetic field strength to 0.3T, and obtain pyrrhotite concentrate and weak magnetic tailings with stronger magnetism;

[0064] S3. Feed the weak magnetic tailings into the strong magnetic separator for strong magnetic roughing, adjust the magnetic field strength to 0.7T, and obtain the weaker magnetic pyrrhotite coarse concentrate and strong magnetic tailings;

[0065] S4. Put the pyrrhotite coarse concentrate into the strong magnetic separator for strong magnetic concentration, adjust the magnetic field strength to 0.6T, and obtain the weaker magnetic pyrrhotite concentrate and magnetic middle ore;

[0066] S5. Merging the pyrrhotite concentrate with stronger magnetism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com