a wc p /Preparation method of high manganese steel-based composite wear-resistant lining plate

A technology of composite wear-resistant lining plate and high manganese steel, applied in the field of composite materials, can solve the problem that it is difficult to take into account the structure and performance of the wear-resistant layer and the matrix layer, the hardenability cannot be well controlled, and the service life of the lining plate is shortened. problems, to achieve good economic applicability, not easy to crack and fall off, and increase the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

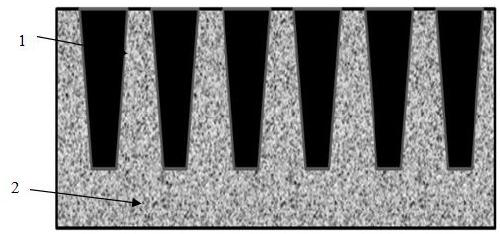

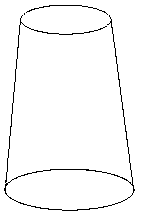

[0028] WC described in this example P / High manganese steel base composite wear-resistant lining plate, tungsten carbide particle size is 60~80 mesh, high manganese steel powder particle size is 200 mesh, such as figure 1 As shown, the thickness of the matrix is 200 mm, the height of the inlay is 100 mm, the inlay is a cylindrical platform, the diameter of the upper circle is 12 mm, and the diameter of the lower circle is 8 mm. The components and weight percentages of the matrix and the inlay are shown in Table 1.

[0029] Table 1

[0030]

[0031] WC described in this example P / High manganese steel matrix composite wear-resistant liner and preparation method thereof, specifically comprising the following steps:

[0032] (1) Powder metallurgy: Mix spherical WC particles with a volume fraction of 10% and high manganese steel powder with a volume fraction of 90% through a ball mill, mill for 2 hours, put the ball-milled powder into a specific mold, and shape it through...

Embodiment 2

[0038] WC described in this example P / High manganese steel base composite wear-resistant lining plate, tungsten carbide particle size is 60~80 mesh, high manganese steel powder particle size is 300 mesh such as figure 1 As shown, the thickness of the matrix is 200 mm, the height of the inlay is 75 mm, the inlay is a cylindrical platform, the diameter of the upper circle is 12 mm, and the diameter of the lower circle is 8 mm. The components and weight percentages of the matrix and the inlay are shown in Table 2.

[0039] Table 2

[0040]

[0041] A WC described in this embodiment P / High manganese steel matrix composite wear-resistant liner and preparation method thereof, specifically comprising the following steps:

[0042] (1) Powder metallurgy: Mix spherical WC particles with a volume fraction of 20% and 80% high manganese steel powder through a ball mill for 2.2 hours of ball milling, put the ball-milled powder into a specific mold and pass it through a press for ...

Embodiment 3

[0048] WC described in this example P / High manganese steel base composite wear-resistant lining plate, tungsten carbide particle size is 60~80 mesh, high manganese steel powder particle size is 400 mesh such as figure 1 As shown, the thickness of the matrix is 200mm, the height of the inlay is 60mm, the inlay is a cylindrical platform, the diameter of the upper circle is 12mm, and the diameter of the lower circle is 8mm. The components and weight percentages of the matrix and the inlay are shown in Table 3.

[0049] table 3

[0050]

[0051] WC described in this example P / High manganese steel matrix composite wear-resistant liner and preparation method thereof, specifically comprising the following steps:

[0052] (1) Powder metallurgy: Mix spherical WC particles with a volume fraction of 30% and high manganese steel powder with a volume fraction of 70% through a ball mill, mill for 2.5 hours, put the ball-milled powder into a specific mold, and shape it through a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com