Formula of 3D printed colored glass product and preparation method of 3D printed colored glass product

A colored glass, 3D printing technology, applied in the direction of additive processing, can solve the problems of long time and complicated operation, and achieve the effect of high surface smoothness, simple production process and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

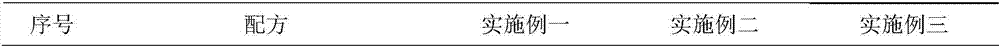

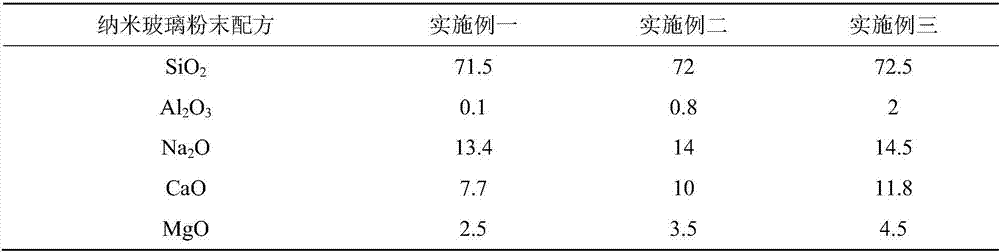

[0031] 80-85 parts of nano glass powder, 15-20 parts of photosensitive resin, 1-3 parts of photoinitiator, 0.05 part of dispersant, 3 parts of ionic colorant, 0.1 part of defoamer,

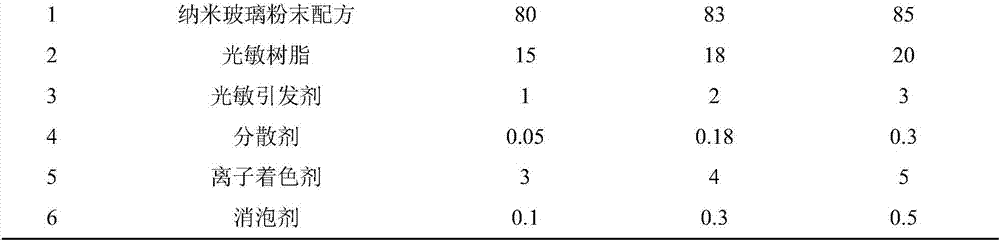

[0032] Wherein the nano glass powder is made up of the following components by weight:

[0033] SiO 2 71.5 parts, Al 2 o 3 0.1 parts, Na 2 O13.4 parts, CaO7.7 parts, MgO2.5 parts.

[0034] The particle size of nano glass powder is 35nm,

[0035] The ionic colorant is one or more of iron compound, manganese compound, cobalt compound, nickel compound, copper compound, solder compound, vanadium compound;

[0036] The photosensitive resin is one or both of acrylate resin or epoxy resin with a viscosity of 130 cm poise.

[0037] The photoinitiator is diphenyl phosphorus oxide, the dispersant is benzoquinone, and the defoaming agent is polydimethylsiloxane.

[0038] Its preparation method comprises the following steps:

[0039] S1: Weigh the nano glass powder, photosensitive resin, photoinitiato...

Embodiment 2

[0043] 83 parts of nano glass powder, 18 parts of photosensitive resin, 2 parts of photoinitiator, 0.18 part of dispersant, 4 parts of ionic colorant, 0.3 part of defoamer,

[0044] Wherein the nano glass powder is made up of the following components by weight:

[0045] SiO 2 72 parts, Al 2 o 3 0.8 parts, Na 2 O14 parts, CaO10 parts, MgO3.5 parts.

[0046] The particle size of nano glass powder is 45nm,

[0047] The ionic colorant is one or more of iron compound, manganese compound, cobalt compound, nickel compound, copper compound, solder compound, vanadium compound;

[0048] The photosensitive resin is one or both of acrylate resin or epoxy resin with a viscosity of 140 cm poise.

[0049]The photoinitiator is diphenyl phosphorus oxide, the dispersant is benzoquinone, and the defoaming agent is polydimethylsiloxane.

[0050] Its preparation method comprises the following steps:

[0051] S1: Weigh the nano glass powder, photosensitive resin, photoinitiator, dispersant,...

Embodiment 3

[0055] 85 parts of nano glass powder, 20 parts of photosensitive resin, 3 parts of photoinitiator, 0.3 part of dispersant, 5 parts of ion colorant, 0.5 part of defoamer,

[0056] Wherein the nano glass powder is made up of the following components by weight:

[0057] SiO 2 72.5 parts, Al 2 o 3 2 parts, Na 2 O14.5 parts, CaO11.8 parts, MgO4.5 parts.

[0058] The particle size of nano glass powder is 50nm,

[0059] The ionic colorant is one or more of iron compound, manganese compound, cobalt compound, nickel compound, copper compound, solder compound, vanadium compound;

[0060] The photosensitive resin is one or both of acrylate resin or epoxy resin with a viscosity of 150 cm poise.

[0061] The photoinitiator is diphenyl phosphorus oxide, the dispersant is benzoquinone, and the defoaming agent is polydimethylsiloxane.

[0062] Its preparation method comprises the following steps:

[0063] S1: Weigh the nano glass powder, photosensitive resin, photoinitiator, dispersan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com