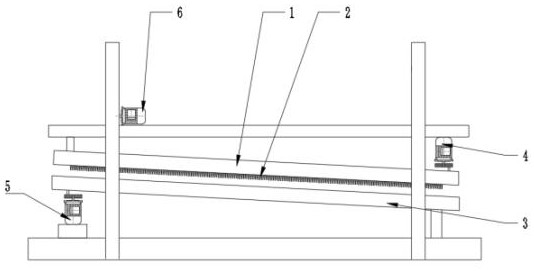

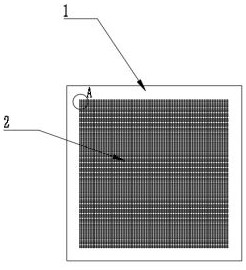

Delinting machine and delinting method

A technology for removing lint and flocking, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of inability to meet production requirements, reduce production efficiency, complex equipment structure, etc., and improve the added value of products. , Improve production efficiency and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the inclination angle of the lower layer plate and the horizontal surface of the sacral machine is 3 degrees, the rotation speed is 85 rpm, the slew radius is 12 cm, and the short velvet is introduced into a group. The upper plate speed is 35 rpm of 35 rpm.

[0047] The fermentation of fermentation of fermentation of fermentation of the fermentation of the fermentation of the fermentation in this example drops to 0.16% (mass content).

Embodiment 2

[0049] In this embodiment, the inclination angle of the lower layer plate and the horizontal plane is 2.5 degrees, the rotation speed is 75 rpm, and the slew radius is 11 cm, and the short velvet is introduced into a group.The upper plate speed is 45 rpm of 45 rpm.

[0050] The fermentation of fermentation of fermentation of fermentation in this example is reduced to 0.15% (mass content).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com