GaN transistor covered with nanopillar barrier and preparation method thereof

A nano-column and transistor technology, applied in the direction of nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problems of complex process, poor controllability, high cost, etc., and achieve simple manufacturing method, reduce epitaxy cost, and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

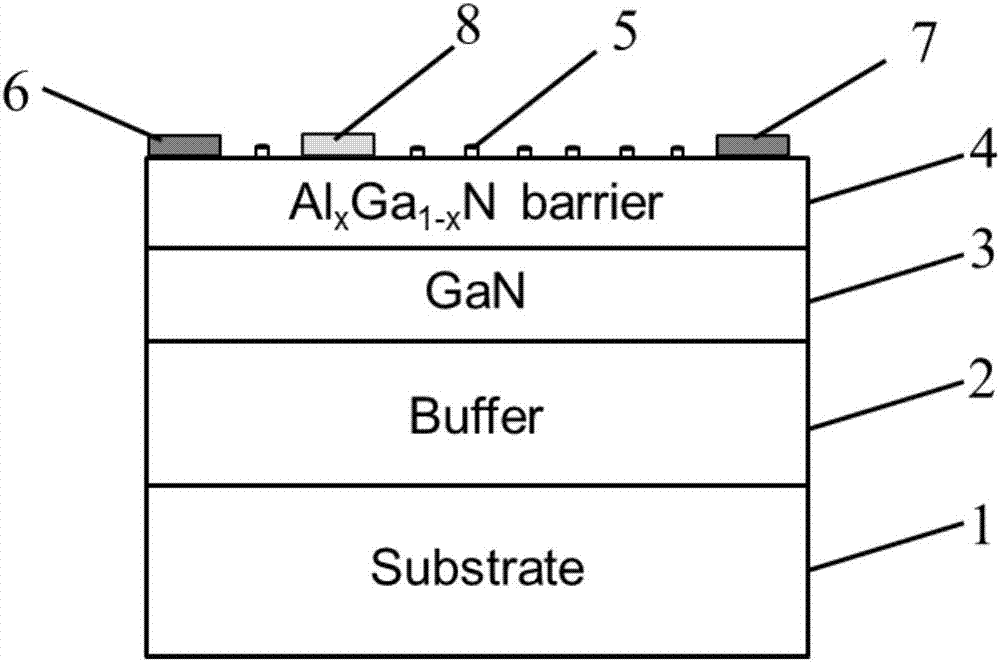

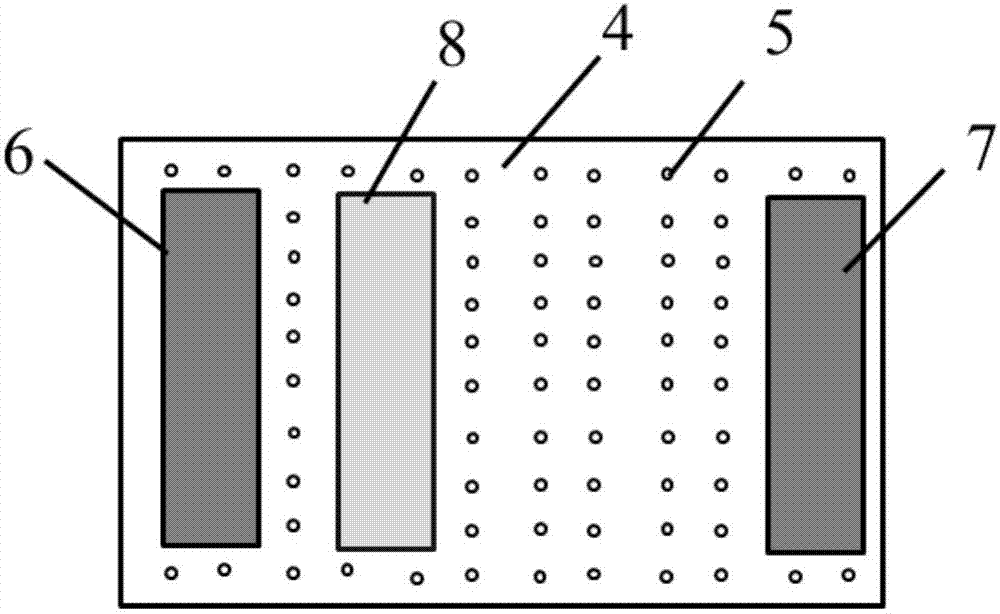

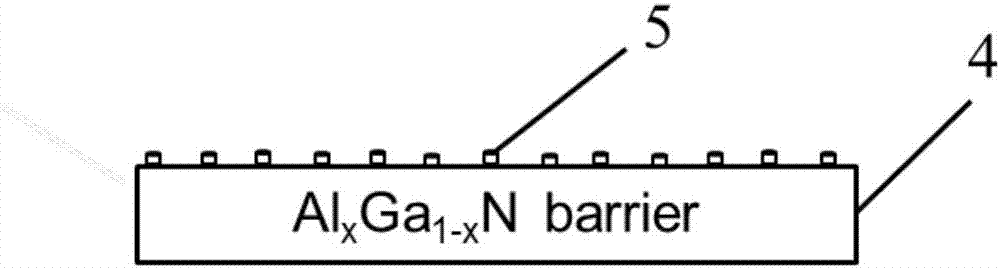

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. All the drawings of the present invention are only schematic diagrams for easier understanding of the present invention, and their specific proportions can be adjusted according to design requirements. The growth conditions of the barriers covering the nanopillars described herein are only examples, and it is still possible to form a barrier structure covering the nanopillars by changing a single condition, which is within the disclosure scope of this specification. The size and number of components in the device manufacturing process described in this article are only examples, and can be adjusted according to actual design requirements.

[0033] refer to figure 1 with figure 2 , a GaN transistor covering a nanocolumn barrier, comprising a substrate 1, a buffer layer 2, a channel layer 3 and a barrier layer 4 covering a nanocolumn 5 from bottom to to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com