Insoluble magnetic cobalt/defective g-C3N4 composite catalyst and application thereof to catalytic Oxone wastewater degradation

A composite catalyst, g-c3n4 technology, applied in catalyst activation/preparation, physical/chemical process catalyst, light water/sewage treatment, etc., can solve problems such as ecological environment and human health hazards, and achieve good insolubility and good catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

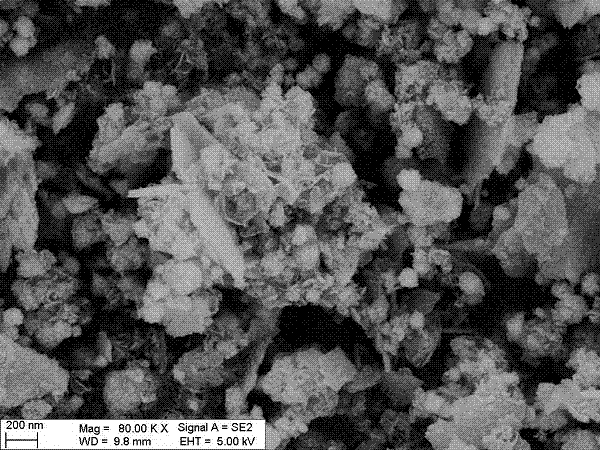

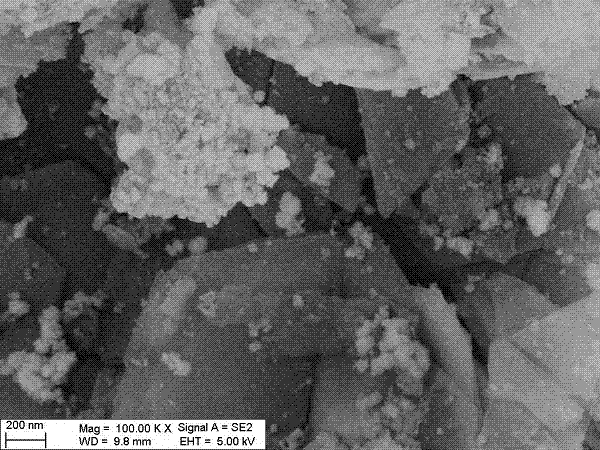

Embodiment 1

[0016] (1) Take 2.703g FeCl 3 ·6H 2 O, 2.780g FeSO 4 ·7H 2 O and 6.033g CoSO 4 ·7H 2 O was dissolved in 20mL of deionized water. After the dissolution was complete, an orange-red mixed solution was obtained. The above mixed solution was heated to 60°C in a water bath and added dropwise to 45mL of ammonia solution with a molar concentration of 3mol / L. During the reaction, black Solids are generated. After the reaction, the turbid liquid containing a large amount of black solids is ultrasonicated at 60°C for 30 minutes under the ultrasonic conditions of 20KHz and 100W, and then cooled to room temperature. After the solid-liquid separation, the black solids are washed with deionized water until neutral, and then Filter, air-dry to obtain the magnetic cobalt catalyst that the mass percentage composition of cobalt is 11%;

[0017] (2) Take 0.7g of melamine, 0.07g of sodium hydroxide and 0.07g of magnetic cobalt catalyst and mix them evenly in a crucible, put the crucible in a ...

Embodiment 2

[0020] (1) Take 2.703g FeCl 3 ·6H 2 O, 2.780g FeSO 4 ·7H 2 O and 6.033g CoSO 4 ·7H2 O was dissolved in 20mL of deionized water. After the dissolution was complete, an orange-red mixed solution was obtained. The above mixed solution was heated to 60°C in a water bath and added dropwise to 45mL of ammonia solution with a molar concentration of 3mol / L. During the reaction, black Solids are generated. After the reaction, the turbid liquid containing a large amount of black solids is ultrasonicated at 60°C for 30 minutes under the ultrasonic conditions of 20KHz and 100W, and then cooled to room temperature. After the solid-liquid separation, the black solids are washed with deionized water until neutral, and then Filter, air-dry to obtain the magnetic cobalt catalyst that the mass percentage composition of cobalt is 11%;

[0021] (2) At room temperature, 10 mL of Oxone with a molar concentration of 0.01 mol / L was added to 50 mL of a levofloxacin solution with a mass concentrati...

Embodiment 3

[0023] (1) Take 2.703g FeCl 3 ·6H 2 O, 2.780g FeSO 4 ·7H 2 O and 6.033g CoSO 4 ·7H 2 O was dissolved in 20mL of deionized water. After the dissolution was complete, an orange-red mixed solution was obtained. The above mixed solution was heated to 60°C in a water bath and added dropwise to 45mL of ammonia solution with a molar concentration of 3mol / L. During the reaction, black Solids are generated. After the reaction, the turbid liquid containing a large amount of black solids is ultrasonicated at 60°C for 30 minutes under the ultrasonic conditions of 20KHz and 100W, and then cooled to room temperature. After the solid-liquid separation, the black solids are washed with deionized water until neutral, and then Filter, air-dry to obtain the magnetic cobalt catalyst that the mass percentage composition of cobalt is 11%;

[0024] (2) Put 0.1.77g of melamine, 0.177g of sodium hydroxide and 0.07g of magnetic cobalt catalyst into a crucible and mix evenly, put the crucible into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com