Phosphoaluminate cement modified sulfoaluminate cement clinker

A technology of sulfoaluminate cement and phosphoaluminate, which is applied in the field of phosphoaluminate cement modified sulfoaluminate cement clinker, can solve problems such as implementation difficulties, and achieve the effect of good seawater scour resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

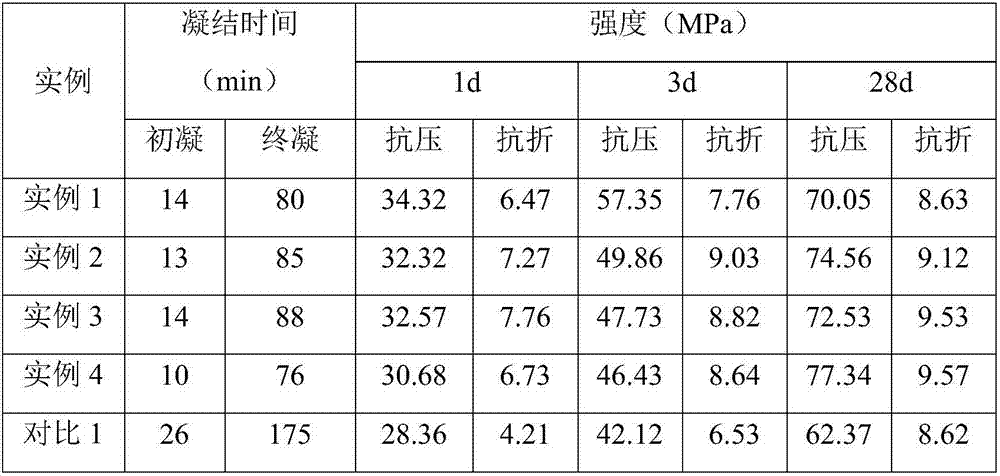

[0013] A kind of aluminum phosphate cement modified sulfoaluminate cement clinker, its raw material component mass percent is CaO42.2%, Al 2 o 3 33.7%, P 2 o 5 11.4%, SO 3 4.8%, Fe 2 o 3 7.9%, mixed according to the design ratio, and the firing temperature was set at 1370°C. The setting time and mechanical properties of the prepared cement clinker are shown in Table 1.

Embodiment 2

[0015] A kind of aluminum phosphate cement modified sulfoaluminate cement clinker, its raw material component mass percent is CaO45.4%, Al 2 o 3 31.8%, P 2 o 5 10.0%, SO 3 4.7%, Fe 2 o 3 8.1%, mixed according to the design ratio, and the firing temperature was set at 1370°C. The setting time and mechanical properties of the prepared cement clinker are shown in Table 1.

Embodiment 3

[0017] A kind of aluminum phosphate cement modified sulfoaluminate cement clinker, its raw material component mass percent is CaO45.8%, Al 2 o 3 31.5%, P 2 o 5 9.9%, SO 3 4.5%, Fe 2 o 3 8.3%, mixed according to the design ratio, and the firing temperature was set at 1370°C. The setting time and mechanical properties of the prepared cement clinker are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com