Waterborne Single-pass Kyocera high-speed ink-jet printing heat transfer ink and preparation method thereof

A technology of inkjet printing and thermal transfer printing, applied in transfer printing, rotary printing machine, printing and other directions, to achieve the effect of reducing the overall cost of printing, smooth printing and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Raw material preparation for a color paste: weigh R60 20%, dispersant HYACT 8.5%, Lubrizol4400 1.5%, emulsifier A 233S 3%, 690W 1.5%, glycerin 20%, Surfynol 104 0.05%, PROXELGXL 0.2% by weight , and the balance is deionized water.

[0048] The preparation method of nano-color paste: mix R60, HYACT, Lubrizol 4400, A233S, 690W, glycerin, Surfynol104, PROXEL GXL and deionized water in proportion to a total of 300KG, put them into a dispersion bucket at 1200rpm to disperse for 2 hours, and then filter through an 80-mesh filter bag After transfer to the grinder for dispersion and grinding, the speed of the grinder is 820rpm, the grinding time is controlled at about 70h, the flow rate of the discharge port is 12-15kg / min, and the temperature of the discharge port is controlled at 40±5°C, and the particle size is 100nm≤D50≤130nm, 250nm≤D99≤280nm nano-scale color paste; the grinding machine is a NETZSCH 25L horizontal nano-sand mill imported from Germany, the cylinder body and ...

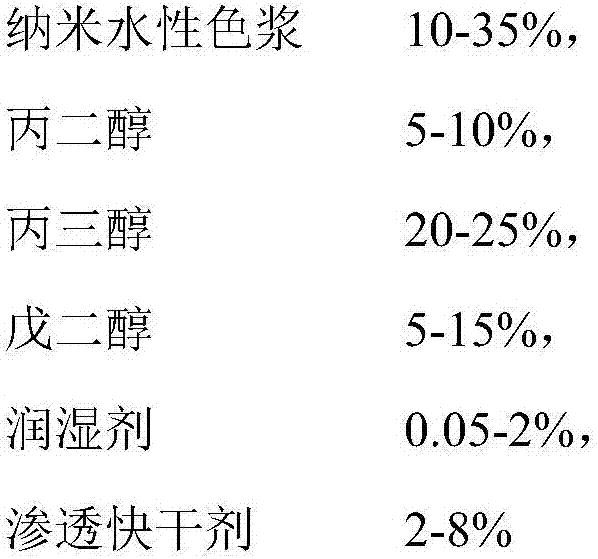

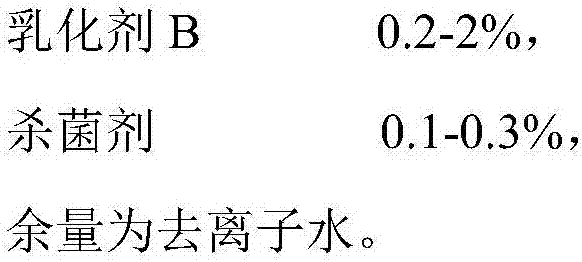

Embodiment 5

[0057] A kind of raw material preparation of water-based Single-pass high-speed inkjet printing thermal transfer printing ink: by weight, take by weighing 32% of the color paste of embodiment 1, propylene glycol (PG) 8%, glycerol (GE) 20%, 1,5-pentanediol 10%, ethylene glycol monobutyl ether 3%, BYK346 0.8%, 607 0.1%, emulsifier B-1580 1.2%, Proxel GXL 0.1%, and the balance is deionized water.

[0058] The preparation method of above-mentioned nanometer ink, comprises the following steps:

[0059] (1) Turn on the mixer, add deionized water, and then add propylene glycol, glycerol, 1,5-pentanediol, ethylene glycol monobutyl ether, BYK346, 607, and emulsifier in sequence while stirring at a speed of 400-600rpm For B-1580 and Proxel GXL, stir for 20-30 minutes until evenly mixed, add the nano-scale dispersion color paste, and continue stirring for 30-60 minutes at a speed of 600 rpm;

[0060] (2) Test the viscosity and surface tension of the homogeneously mixed mixture in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com