Testing apparatus and method for testing tensile strength of fissured rock

A technology of tensile strength and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of not satisfying the center cracking condition, the error of the tensile strength formula, and weakening the tensile strength of the rock block. To achieve the effect of avoiding waste of materials and costs, novel and reasonable design, and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

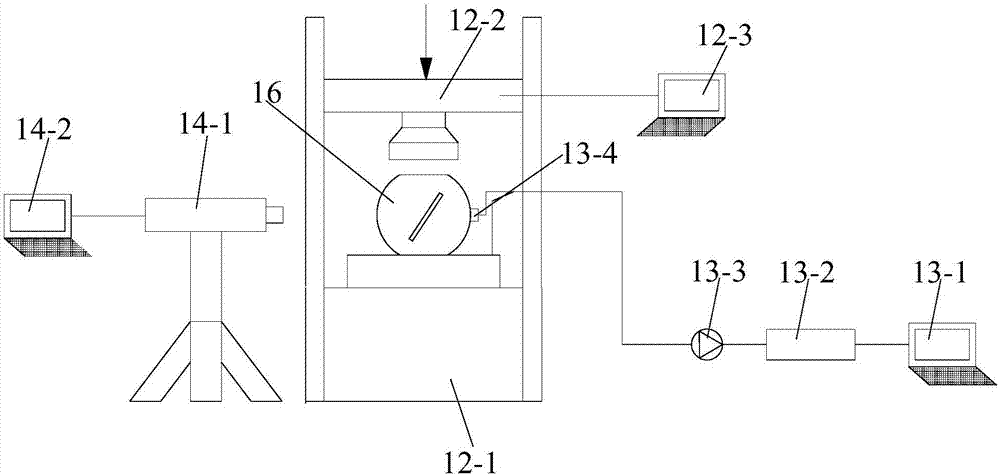

[0070] Such as figure 1 and figure 2 As shown, the test device for testing the tensile strength of rocks containing fissures of the present invention includes a Brazilian sample processing device for processing fissure-containing platform Brazil sample 16 for processing the rock-like material into a fissure-containing platform Brazil sample 16 and is used to give a fissure-containing platform The stress loading system for loading stress on Brazilian sample 16, and the acoustic emission system used to collect the acoustic emission characteristic parameters of the internal structural damage evolution process of the cracked platform Brazil sample 16 during the stress loading process and the acoustic emission system for collecting the stress during the stress loading process The VIC-3D non-contact full-field strain measurement system of the surface mesostructure change image of Brazilian sample 16 with a cracked platform;

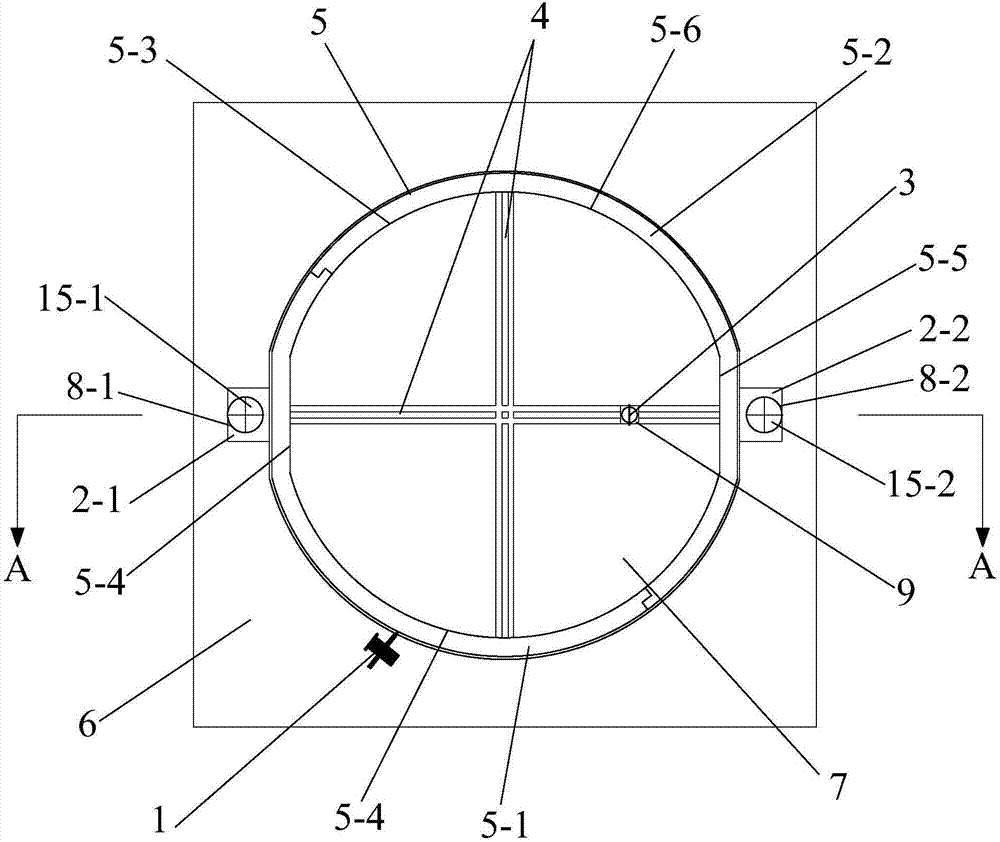

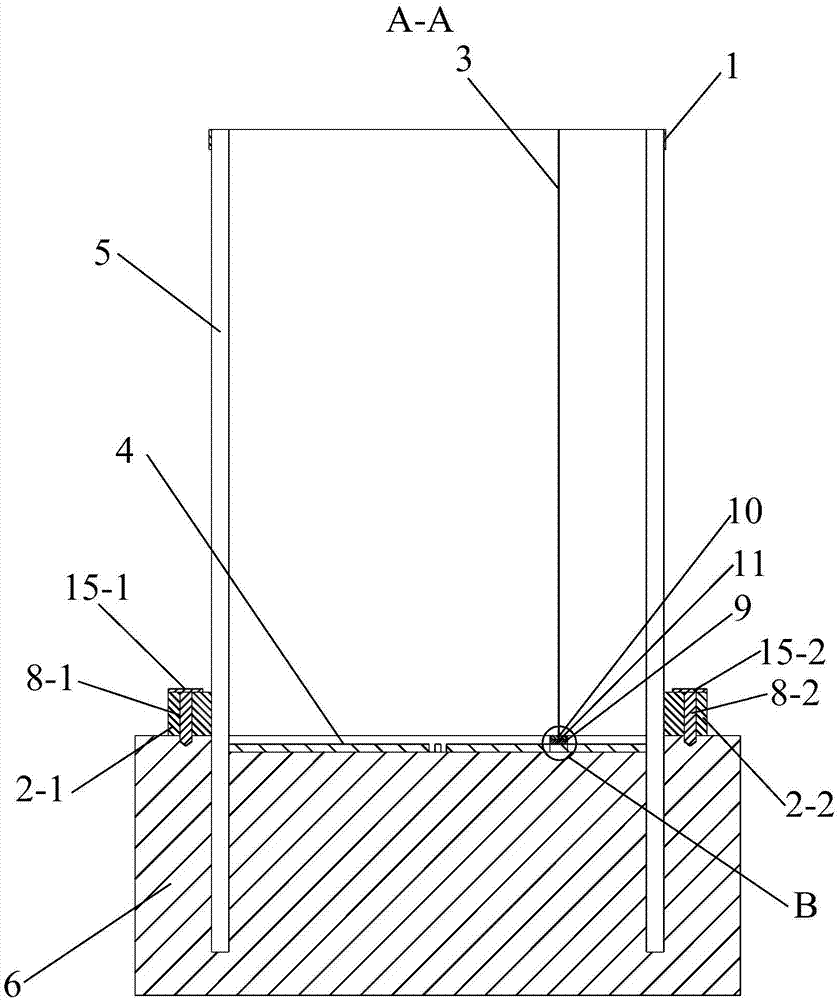

[0071] Such as figure 2 , image 3 and Figure 4 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com