New low-pass filter using solenoid type silicon-through-hole inductor

A low-pass filter and through-silicon via technology, which is applied in the field of passive electronic devices, can solve the problems of filter occupied area and packaging cost that cannot meet requirements, and achieves improved performance, short interconnect length, and reduced physical size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] The low-pass filter of the present invention is composed of multiple element units, and the input and output ports are located in the re-layout layer on the top of the substrate.

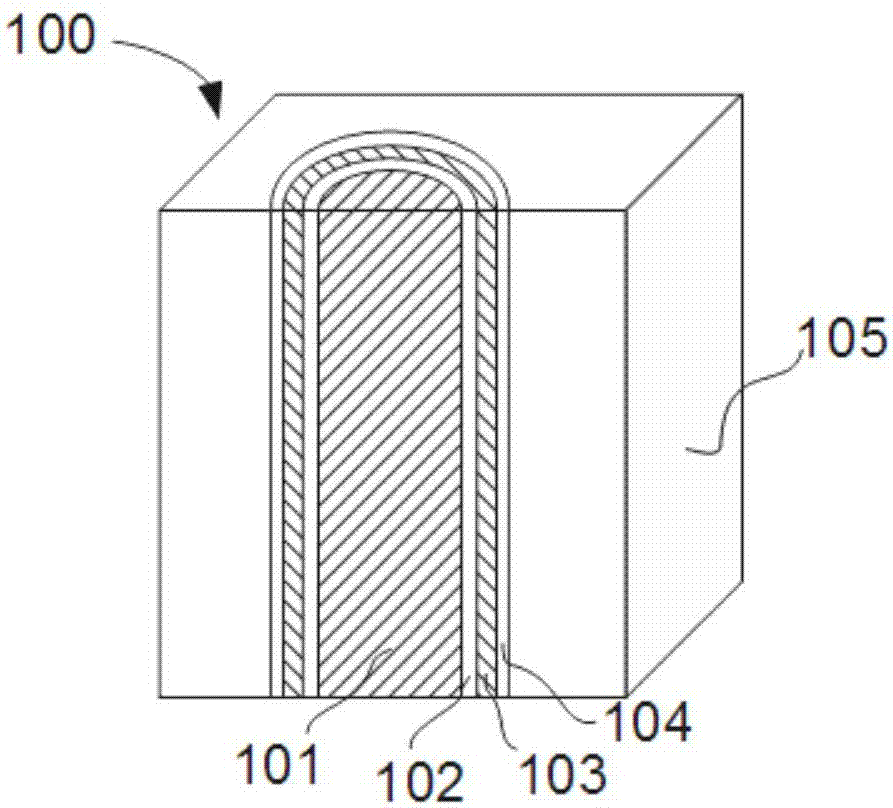

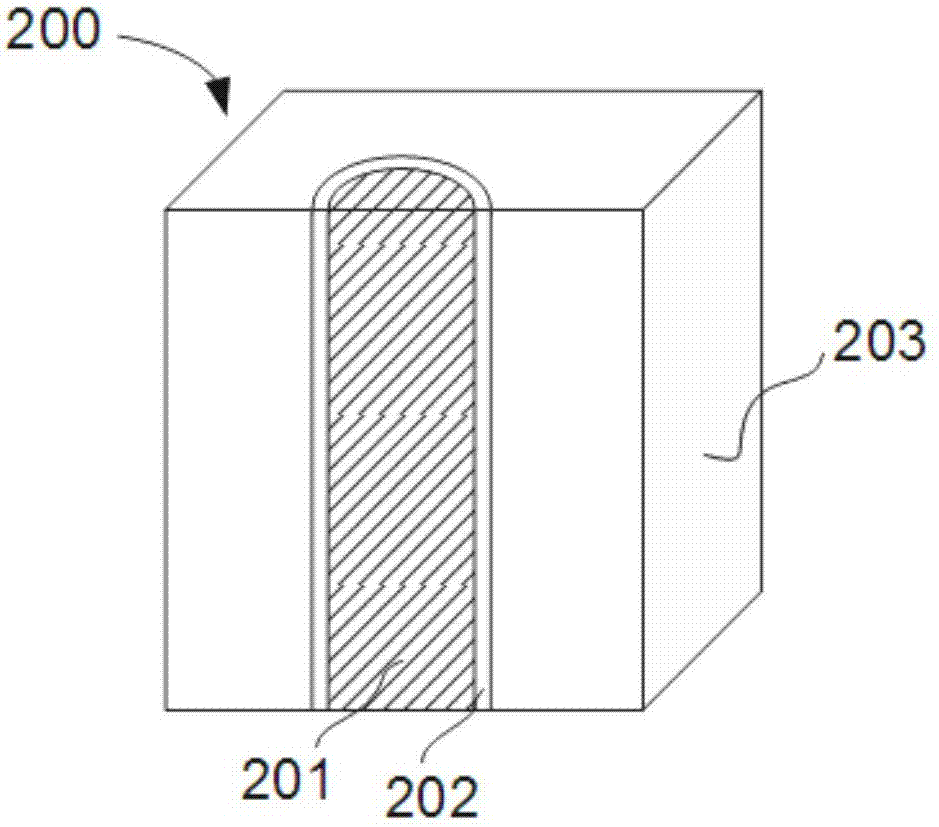

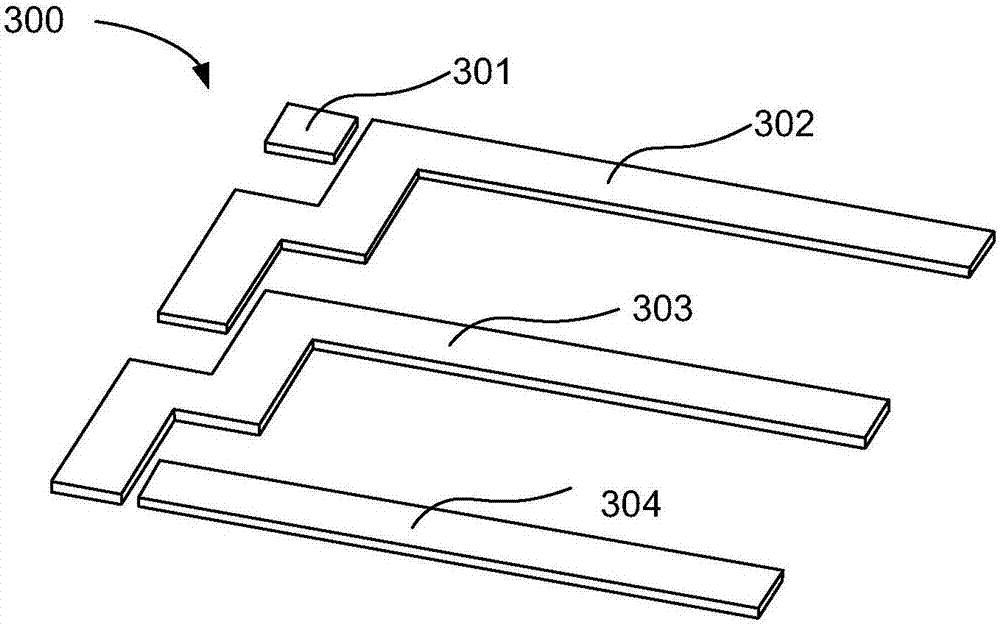

[0030] The element unit includes a solenoid-type TSV inductor 600, first and second coaxial TSV capacitors 700, 800, and first to third connecting substrates 900-1100. The solenoidal TSV inductor 600 includes a substrate top reconfiguration layer 300 , two columns of TSV arrays 400 and a substrate bottom reconfiguration layer 500 .

[0031] The top re-layout layer of the solenoidal TSV inductor substrate includes first to fourth substrates 301-304, which are in the same plane and not connected to each other; the second substrate 302 and the third substrate 303 are parallel to each other. The reconstruction layer 500 at the bottom of the base includes first to third substrates 501-503, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com