Preparation method for angelica sinensis extract with baking fragrance, and application of same

An angelica extract and a technology of angelica, which are applied in the field of preparation of angelica extract to achieve the effects of overcoming turbidity of smoke, improving aroma quality and increasing richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

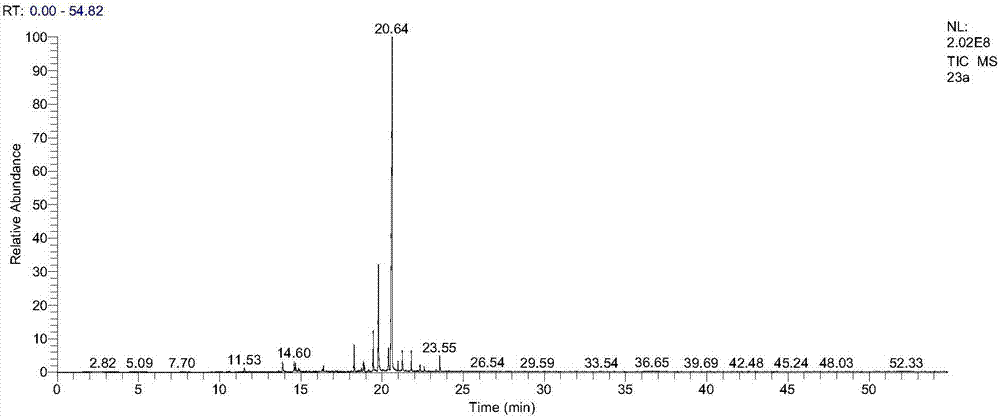

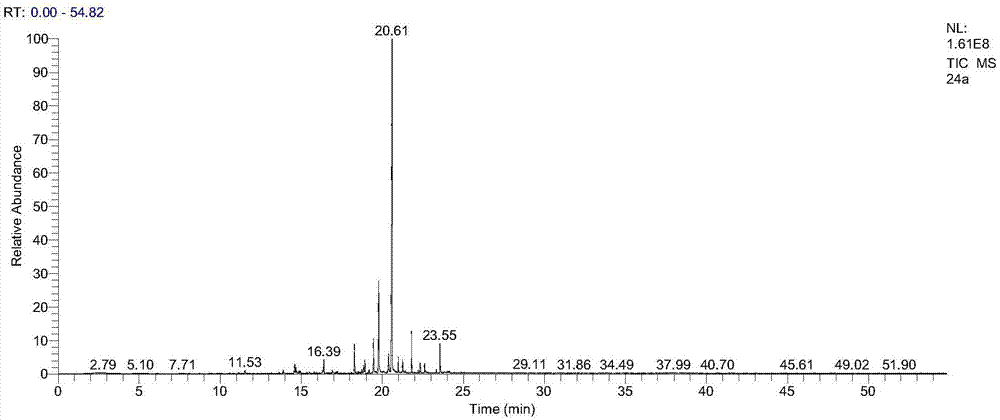

Image

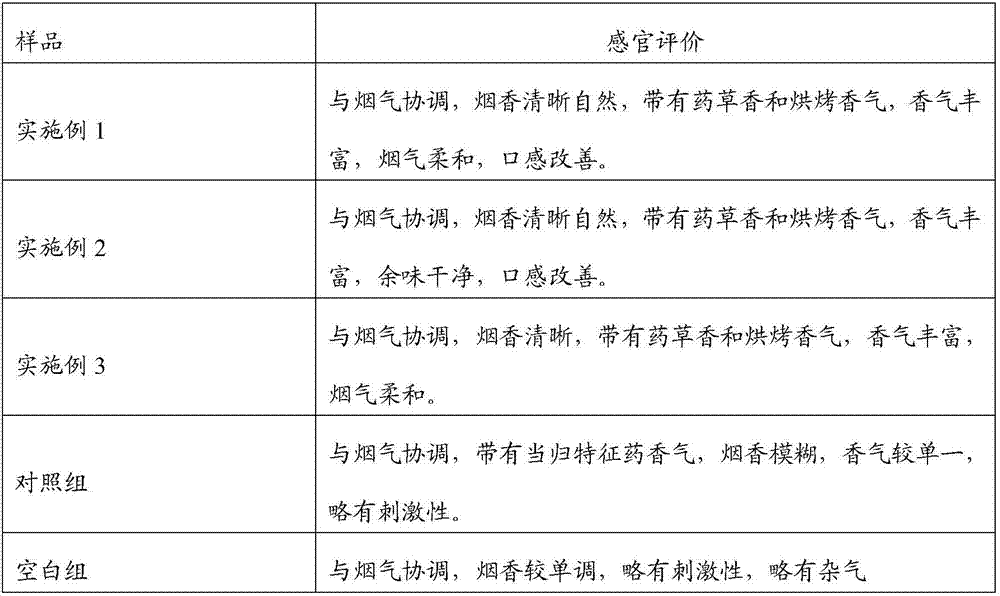

Examples

Embodiment 1

[0029] A preparation method of angelica sinensis extract with roasted aroma, comprising the steps of:

[0030] (1) Pulverization and wall breaking: put the root of Angelica sinensis into a liquid nitrogen frozen ultrafine pulverizer and pulverize it into ultrafine powder at -2°C, the mesh number is 280 mesh, and mix the ultrafine powder and water at a mass ratio of 1:10 Evenly, pour into a high-pressure extraction tank, pressurize to 31MPa, and extract for 10 minutes;

[0031] (2) Biotransformation: Add lactic acid (food grade, accounting for 1.5% of the raw material quality of Angelica sinensis) in the extraction tank, adjust pH5.0, add compound biological preparation (548-D fusion Lactobacillus weissnerii, β-glucosidase, acid Protease, polysaccharase, food grade, compound biological preparations account for 0.3% of the mass of angelica raw materials, the ratio between them is 1:0.5:0.5:1 by mass, and the enzyme activities are 10,000 u / g and 50,000 u / g respectively u / g, 50,0...

Embodiment 2

[0036] A preparation method of angelica sinensis extract with roasted aroma, comprising the steps of:

[0037] (1) Pulverization and wall breaking: put the root of Angelica sinensis into a liquid nitrogen frozen ultrafine pulverizer and pulverize it into ultrafine powder at 0°C, with a mesh number of 300 mesh, and mix the ultrafine powder and water evenly at a mass ratio of 1:20 , pour it into a high-pressure extraction tank, pressurize to 45MPa, and extract for 7.5 minutes;

[0038] (2) Biotransformation: Add lactic acid (food grade, accounting for 0.5% of the raw material quality of Angelica sinensis) in the extraction tank, adjust pH6.5, add compound biological preparation (548-D fusion Lactobacillus weissnerii, β-glucosidase, acid Protease, polysaccharase, food grade, compound biological preparations account for 0.2% of the mass of angelica raw materials, the ratio between them is 1:0.5:0.5:2 by mass ratio, and the enzyme activities are 1000u / g and 100,000u / g respectively ...

Embodiment 3

[0043] A preparation method of angelica sinensis extract with roasted aroma, comprising the steps of:

[0044] (1) Pulverization and pressure breaking: Put the root of Angelica sinensis in a liquid nitrogen frozen superfine pulverizer and pulverize it into a superfine powder with a mesh number of 320 mesh. Mix the superfine powder and water at a mass ratio of 1:40 Evenly, pour into a high-pressure extraction tank, pressurize to 55MPa, and extract for 5 minutes;

[0045] (2) Biotransformation of compound biological preparations: add lactic acid (food grade, accounting for 0.1% of the quality of Angelica sinensis raw material) in the extraction tank, adjust pH 6.5, add compound biological preparations (548-D fusion Lactobacillus weissnerii, β-glucosidase , acid protease, polysaccharase, and compound biological preparations account for 0.1% of the mass of angelica raw materials. The ratio between them is 1:1:1:0.5 by mass, and the enzyme activities are 500u / g and 100,000u / g respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com