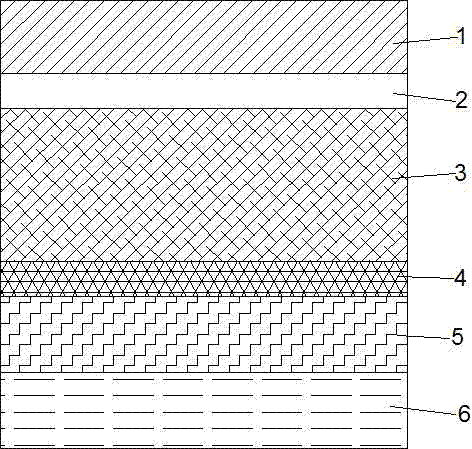

Corrosion resistant aluminum plastic film for lithium battery packaging

A lithium battery, corrosion-resistant technology, applied in applications, electronic equipment, household appliances, etc., can solve problems such as high cost, unsuitable for industrial production, complex process, etc., achieve high chemical resistance, improve mechanical properties and electrolyte resistance performance, the effect of improving corrosion resistance and easy bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments.

[0023] Table 1 Distinguishing features of embodiment and comparative example

[0024]

[0025] According to Table 1, each embodiment and comparative example were manufactured to manufacture aluminum-plastic film, and for other parameters not involved in Table 1, each embodiment was consistent with the comparative example. Carry out cohesive force test to embodiment and comparative example, and the cohesive force test after electrolyte solution immersion.

[0026] Table 2: The comparison of cohesive force is as follows: (Unit: N / 15mm)

[0027] project

[0028] According to the comparison results of the above performance tests, comparing Examples 1, 2, 3 and Comparative Examples 3, 4, it can be seen that controlling the thickness of the structural layer and the thickness of the barrier layer within a certain proportion can effectively improve the anti-ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com