Method for cleaning treatment of high-ammonia-nitrogen wastewater containing metal ions

A metal ion and cleaning treatment technology, which is applied in the cleaning treatment of high ammonia nitrogen wastewater and the field of wastewater treatment, can solve the problems of ammonia gas escape, reduce the removal rate of metal cations and ammonia nitrogen, and achieve the effect of high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

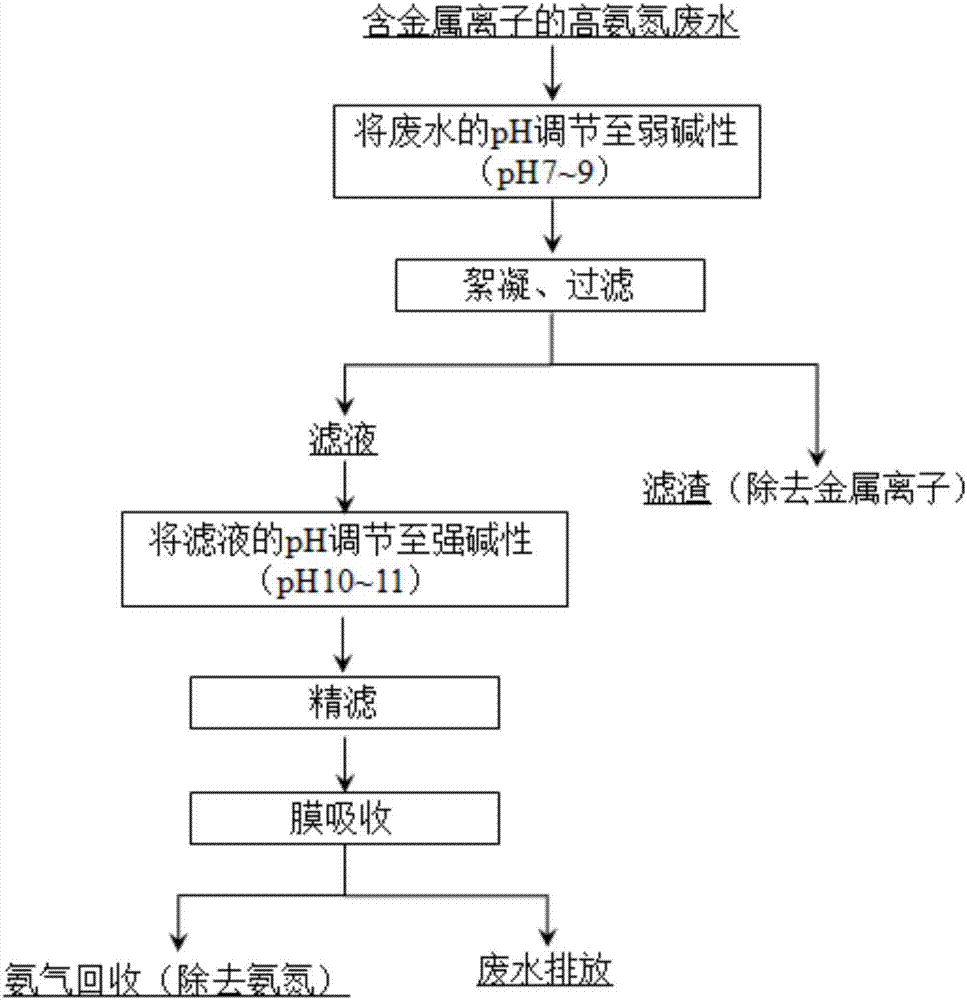

Method used

Image

Examples

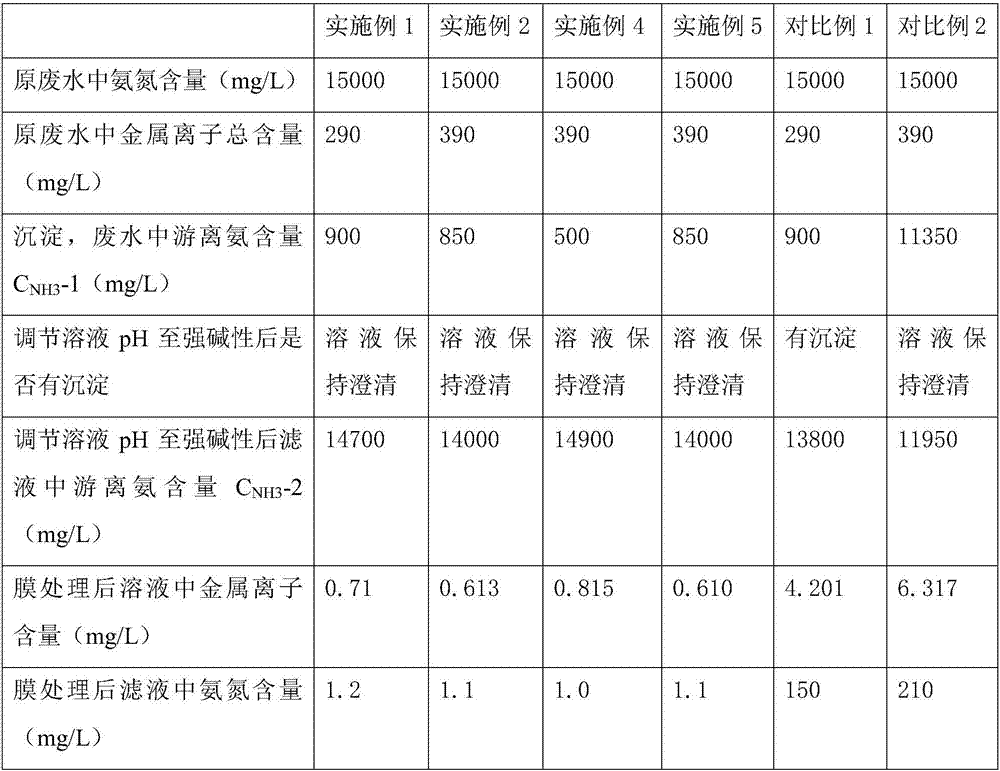

Embodiment 1

[0071] The simulated wastewater is metal-containing high-concentration ammonia-nitrogen composite wastewater formulated with metal salts, sulfurous acid, sulfuric acid, and ammonium sulfate. The total iron in the wastewater is 120mg / L, the total aluminum is 80mg / L, the total calcium is 90mg / L, and the ammonia nitrogen is 15000mg. / L, pH=0.58.

[0072] 1) The simulated wastewater was prepared by 15% NaOH and 5% Na 2 CO 3 The mixed alkali of composition adjusts the pH of the solution to 8. At this time, it can be observed that a large amount of precipitation can be formed in the solution, and the concentration of free ammonia in the detection solution is C NH3 -1;

[0073] 2) Add one ten-thousandth of non-ionic polyacrylamide to the waste water, most of the metal precipitates can be flocculated and precipitated; then filter to obtain the filtrate and filter residue;

[0074] 3) The filtrate is transferred to a tubular mixer, and the pH of the solution is adjusted to 11 by sod...

Embodiment 2

[0077] The simulated wastewater is metal-containing high-concentration ammonia-nitrogen composite wastewater formulated with metal salts, sulfurous acid, sulfuric acid, and ammonium sulfate. The total iron in the wastewater is 120mg / L, the total lead is 100mg / L, the total aluminum is 80mg / L, and the total calcium is 90mg. / L, ammonia nitrogen is 15000mg / L, pH=0.58.

[0078] 1) The simulated wastewater is made of 15% KOH and 5% KHCO 3 The mixed alkali of composition adjusts the pH of the solution to 8. At this time, it can be observed that a large amount of precipitation can be formed in the solution, and the concentration of free ammonia in the detection solution is C NH3 -1;

[0079] 2) Add one ten-thousandth of non-ionic polyacrylamide to the waste water, most of the metal precipitates can be flocculated and precipitated; then filter to obtain the filtrate and filter residue;

[0080] 3) The filtrate is transferred to a tubular mixer, and potassium hydroxide solution is us...

Embodiment 3

[0083] Repeat Example 2, but also include:

[0084] 5) carry out metal recovery with the filter residue that step 2) obtains;

[0085] 6) The filtrate after the ammonia removal in step 4) is directly discharged or recycled. The ammonia obtained during the ammonia removal process is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com