Sewage treatment equipment

A technology of sewage treatment equipment and water wheel, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor water purification effect and insufficient water mixing, etc. Achieve better water purification effect, improve disinfection effect, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further detailed explanation through specific implementation mode below:

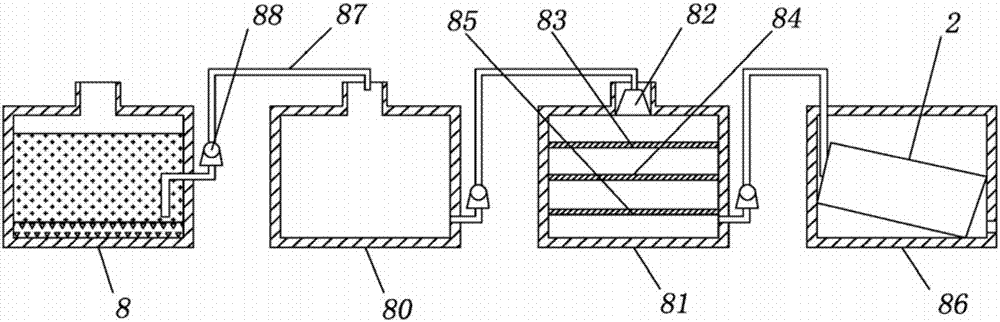

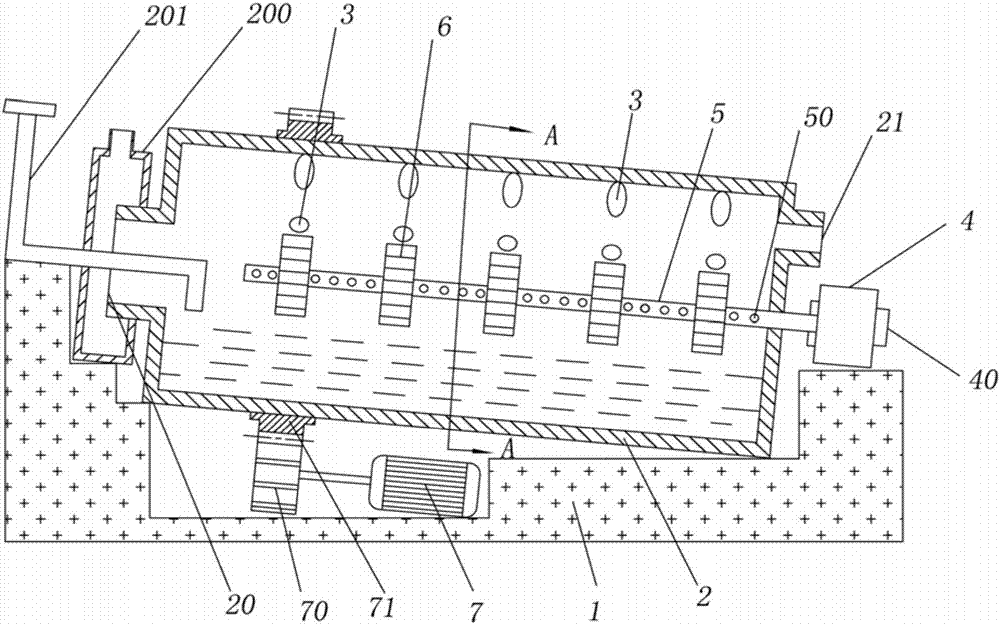

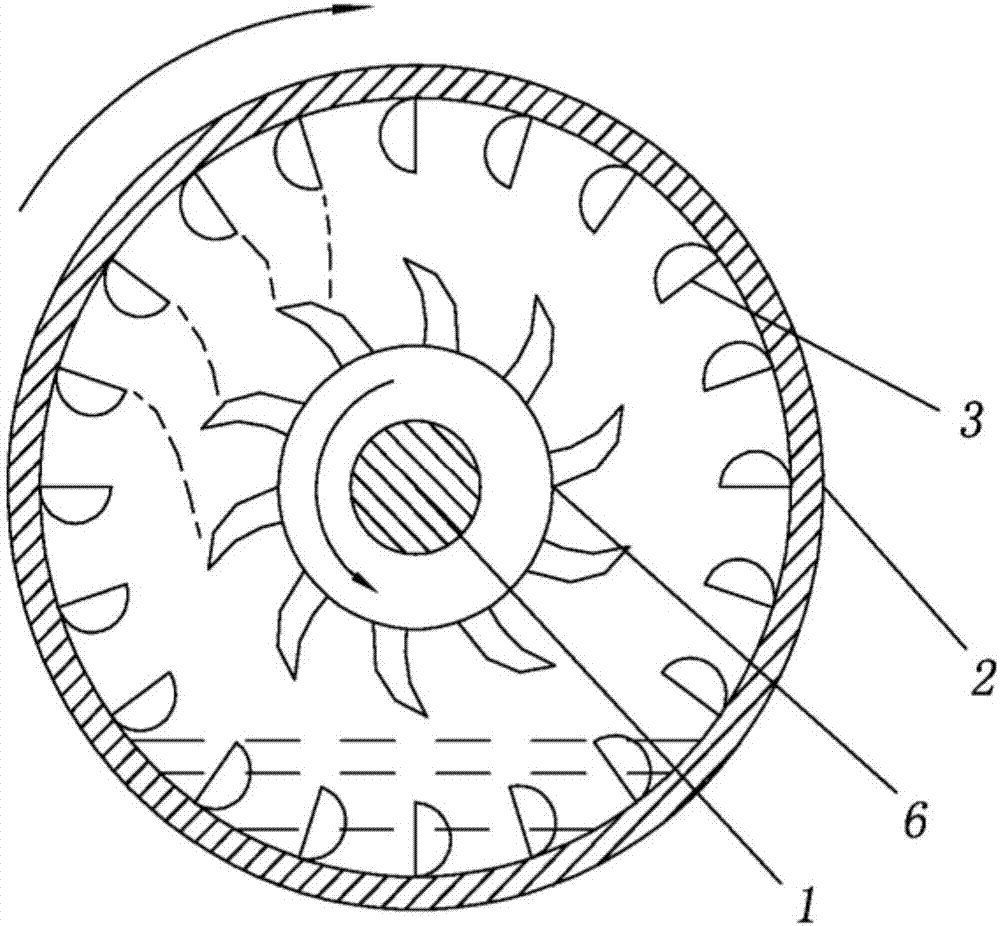

[0027] The reference signs in the drawings of the description include: support frame 1, clean water bucket 2, water inlet 20, exhaust pipe 200, water inlet pipe 201, water outlet 21, water bucket 3, thick diameter pipe 4, air inlet 40, Small-diameter tube 5, blowing hole 50, water wheel 6, motor 7, driving gear 70, passive gear 71, sedimentation tank 8, coagulation tank 80, filter tank 81, water spray head 82, coarse filter layer 83, fine filter layer 84, refilter layer 85, disinfection pool 86, suction pipe 87, water pump 88.

[0028] The embodiment is basically as figure 1 Shown:

[0029] The sewage treatment equipment includes a sedimentation tank 8, a coagulation tank 80, a filter tank 81 and a disinfection tank 86 connected in sequence. A suction pipe 87 is connected between each treatment pool, and a water pump 88 is provided on the suction pipe 87 . A coarse filter layer 83 , a fine fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com