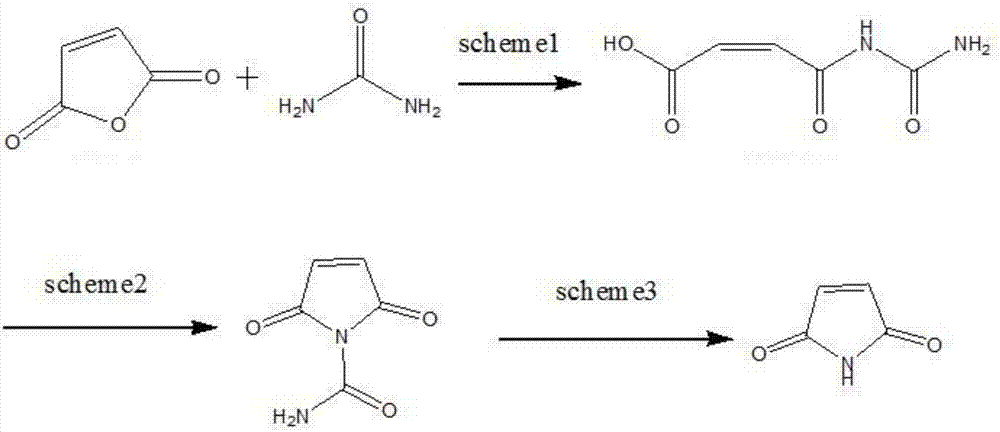

Synthesis method of maleimide

A technology of maleimide and synthesis method, applied in directions such as organic chemistry, can solve problems such as unfavorable industrial production, high boiling point of DMF, dark color of crude product, etc., and achieve the effects of easy industrial production, high product quality, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Wash the 500L reaction kettle, add 100kg maleic anhydride and 61kg urea, cover the kettle, vacuum pump 150kg of glacial acetic acid, start stirring, start to heat up to 50-60°C to react, react for 18h, HPLC detects that the raw materials disappear.

Embodiment 2

[0021] Cool down the product from the previous step to about 25°C, vacuum pump 150kg of acetic anhydride, control the temperature at about 85°C, react for 2 hours, and detect the disappearance of raw materials by HPLC. The solvent was concentrated in vacuo to 75°C, 200 kg of ethyl acetate was sucked in by vacuum, centrifuged, and the solid was washed with ethyl acetate.

Embodiment 3

[0023] The above solid was transferred to a reaction kettle, 300 kg of ethyl acetate and 2.5 kg of triethylamine were sucked in by vacuum, heated to reflux, reacted for 2 hours, and the raw materials disappeared by HPLC detection. Cool down to 25°C, centrifuge, and wash the solid with ethyl acetate. The filtrate was washed 3 times with 50kg, 25kg, and 25kg deionized water respectively. Concentrate ethyl acetate, suck in 30kg of ethyl acetate to crystallize under vacuum, recrystallize twice with 30kg of water, and dry to obtain about 40kg of white solid, which is maleimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com