Rubber lining composition used at high temperature as well as preparation method and purpose of rubber lining composition

A technology of rubber lining and composition, which is applied in the field of rubber polymer materials and materials, can solve the problems of poor high temperature resistance of natural rubber, etc., and achieve the effects of improving hardness and temperature resistance, reducing protein content, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

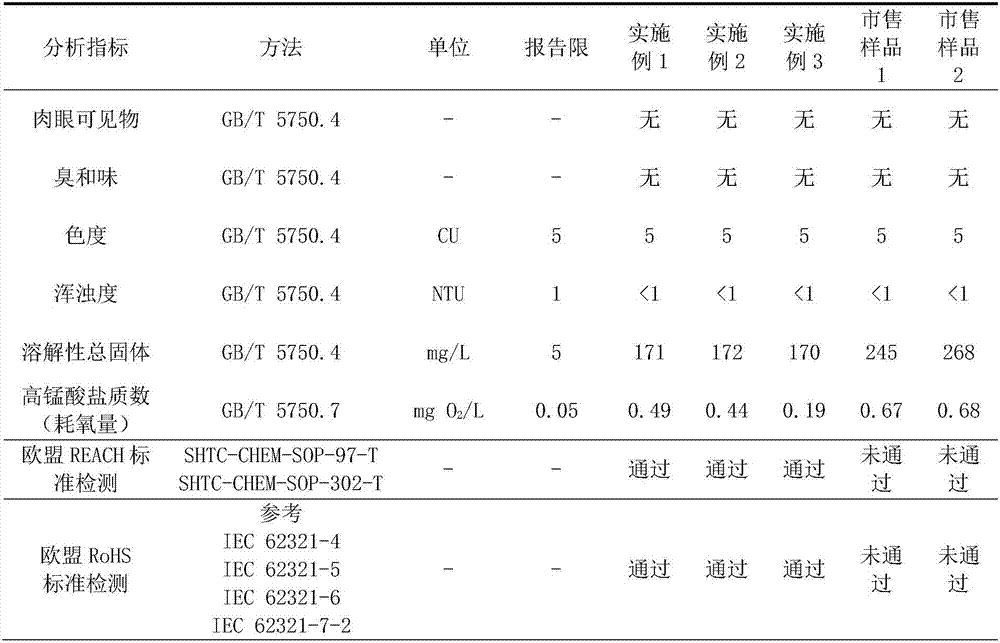

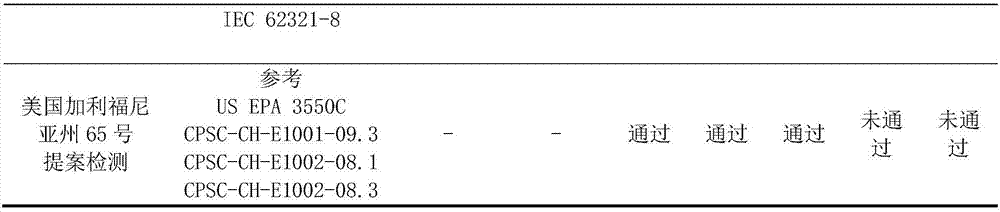

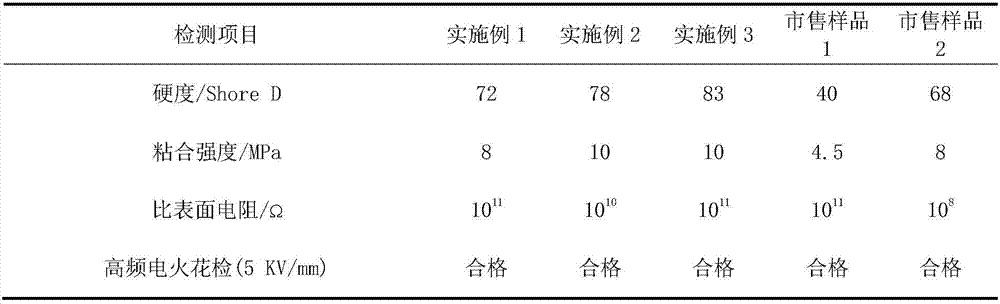

Examples

Embodiment 1

[0041] (1) Weigh each component according to the following proportions: 40kg of natural rubber, 5kg of styrene-butadiene rubber, 5kg of high-styrene rubber, 2.5kg of nano-zinc oxide, 5kg of nano-carbon black, 7.5kg of filler, 12.5kg of sulfur, and 0.25 kg of accelerator kg, put the above raw materials in an open mill or an internal mixer for rubber mixing, extrude the mixed rubber film, and then extrude the film on the extruder or calender, with a thickness of 3.5mm;

[0042](2) Sandblast the metal surface of the equipment that needs to be lined with rubber. The sandblasting grade is Sa 2.5. After cleaning, brush SP-2 red adhesive within 4 hours, and after 5 hours of air drying, brush SP-2 red for the second time Adhesive, air-dry for 5 hours, and then apply SP-2 red adhesive;

[0043] (3) Cut the rubber sheet according to the size of the equipment. Brush the surface of the rubber sheet with SP-2 red adhesive. After air-drying for 10 hours, spread it on the surface of the equi...

Embodiment 2

[0050] Compared with Example 1, the amount of nano carbon black in the first step becomes 12.5kg, the amount of filler becomes 10kg, the amount of sulfur becomes 17.5kg, the amount of accelerator becomes 0.4kg, and other conditions remain unchanged.

Embodiment 3

[0052] Compared with embodiment 1, in the first step, the natural rubber consumption becomes 31kg, the styrene-butadiene rubber consumption becomes 9kg, the high styrene rubber consumption becomes 10kg, the filler consumption becomes 10kg, and the sulfur consumption becomes 17.5kg, promotes The dosage becomes 0.45kg, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com