Continuous electrode electrolytic cell for metal material preparing

A metal material and electrolytic cell technology, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of complex anode and cathode control replacement process, inconvenient cleaning and operation, slow down of electrolysis rate, etc., and achieve balanced and stable product quality , The effect of low manufacturing cost and accelerated efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

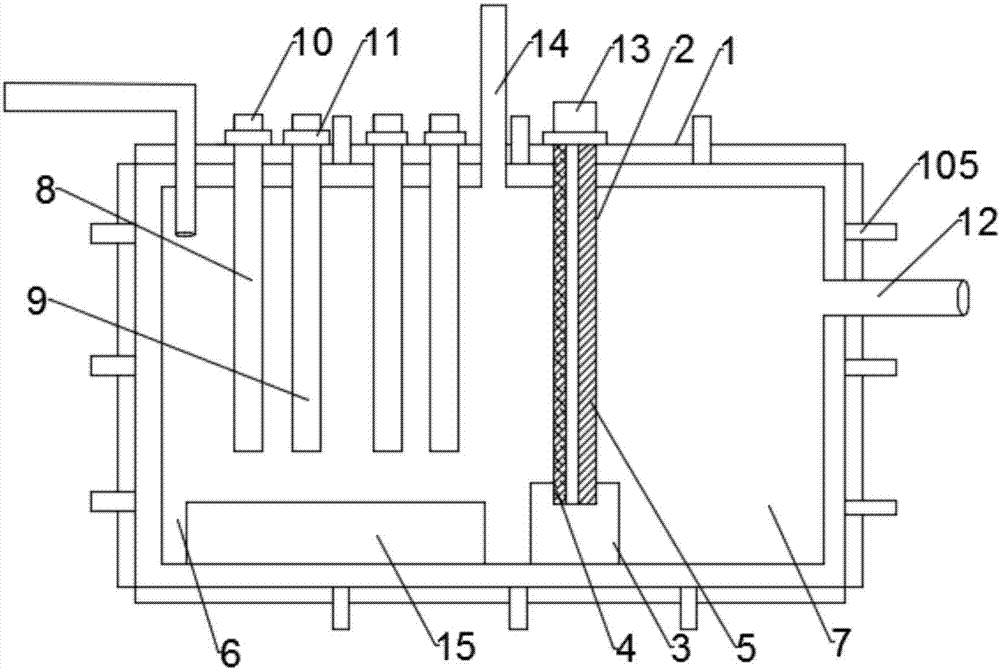

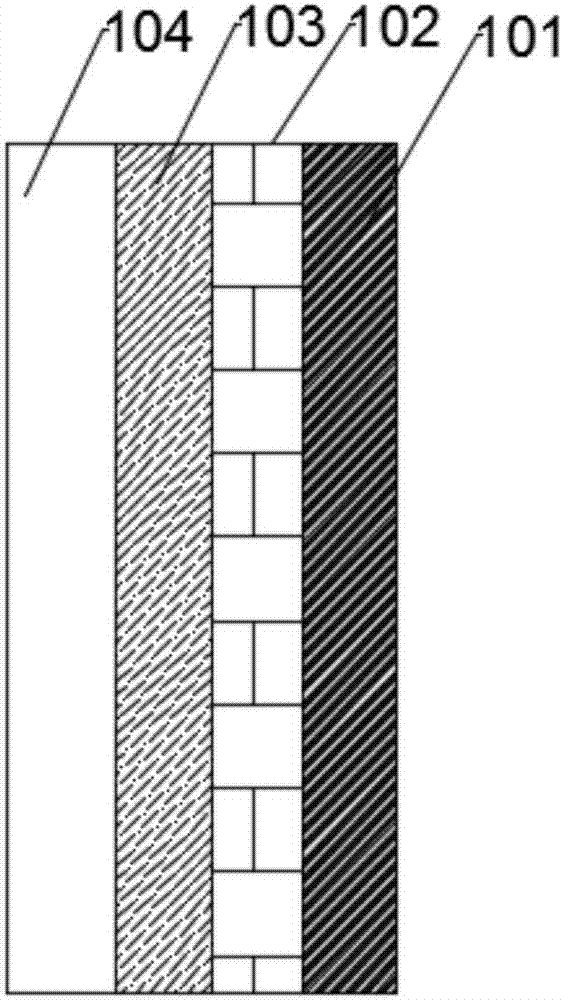

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a continuous electrode electrolytic cell for metal material preparation, comprising an electrolytic cell body 1, the electrolytic cell body 1 is a cuboid shape, and the outer side of the electrolytic cell body 1 surrounds its surface, There are also several horizontal partitions 105 from top to bottom, the number of the horizontal partitions 105 is three or four, and the insulation material is filled between the horizontal partitions 105, and the electrolytic cell body 1 from From the inside to the outside, it is composed of synthetic gum lining 101, clay brick non-working layer 102, thermal insulation layer 103 and steel body shell 104. The insulation material added on the periphery of the electrolytic cell 1 is to increase the thickness of the electrolytic cell. 1 corner insulation, and reasonably control the thickness of the insulation material on different parts of the anode rod 8 and cathode r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com