Short dyeing and finishing process for polyester and viscose blended fabric

A blended fabric and short-process technology, applied in the field of fabric dyeing and finishing, can solve the problems of high production cost, high energy consumption and water consumption, and achieve the effects of saving energy, improving production efficiency, and shortening the dyeing and finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

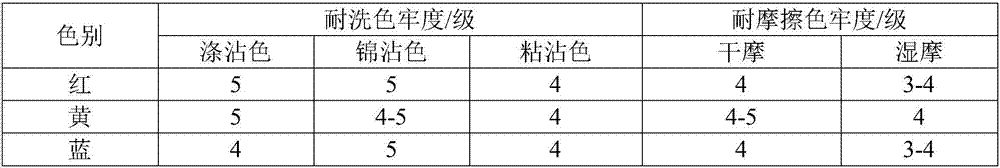

Examples

Embodiment 1

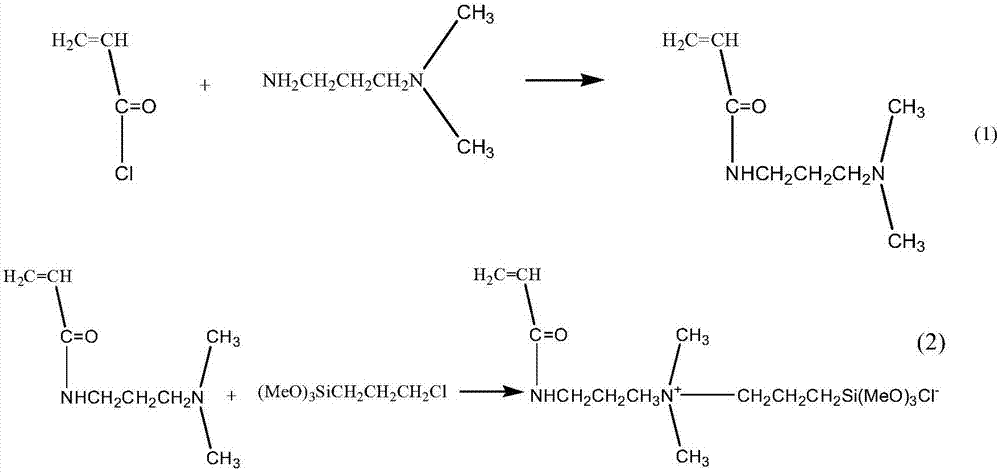

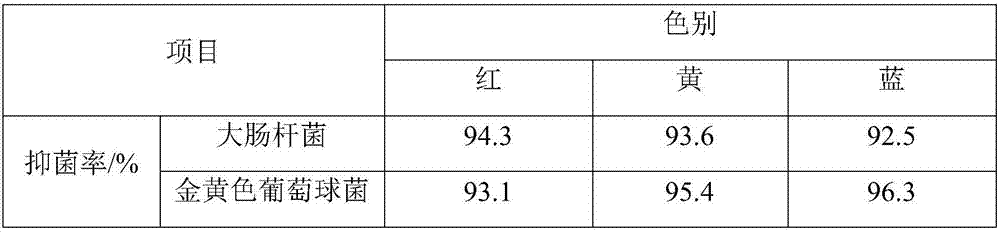

[0035] The preparation method of antibacterial finishing agent is:

[0036] Nano-titanium dioxide powder was pre-dried in a vacuum oven at 80°C for 4 hours, weighed 20 parts into a jar filled with 150mL of absolute ethanol and 50mL of water, ultrasonically dispersed for 30min, then transferred to a three-necked flask, and put Stir in a constant temperature water bath at a constant speed, adjust the pH value to 6.5 with HCl, add 5 parts of coupling agent KH-570 and 12 mL of anhydrous ethanol mixture from the bottle mouth through a dropper after the stirring is stable, take it out after 2 hours of reaction, filter and wash, The obtained solid was Soxhlet extracted with absolute ethanol for 24 hours, and then dried in a vacuum oven at 80°C for 12 hours to obtain surface-modified nano-titanium dioxide;

[0037] Add 214 parts of water and 13 parts of cationic surface-modified nano-titanium dioxide into the reaction kettle, stir to dissolve and disperse for 30 minutes, raise the tem...

Embodiment 2

[0042] Short-process dyeing and finishing process of polyester-nylon-viscose blended fabrics, the technological process is one-bath pretreatment→polyester-nylon-viscose dyeing in the same bath→soaping→functional finishing;

[0043] 1) One-bath pretreatment:

[0044] According to the bath ratio of 1:10, put gray cloth and clear water in the machine tank; add alkali-resistant high-efficiency scouring agent XY-1 2g / L, oxygen bleaching stabilizer CN-215 2g / L, hydrogen peroxide 3g / L, chelating dispersant DR-520 2g / L, sodium hydroxide 3g / L; heat up to 98°C at a rate of 2°C / min, keep warm for 30min; cool down to 50°C, discharge waste liquid, and wash with water;

[0045] 2) Dyeing of polyamide and viscose in the same bath:

[0046] According to the bath ratio of 1:10, put the pre-treated polyester cotton cloth and clear water in the machine tank; add disperse dyes, neutral color-fixing reactive dyes, neutral dyes, sodium chloride 20-40g / L, leveling agent 1 -3g / L; heat up to 120°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com