Exhaust gas recirculating device for marine diesel engine

A technology for exhaust gas recirculation and marine diesel engines, which is applied in the direction of exhaust gas recirculation, exhaust devices, noise reduction devices, etc., can solve problems affecting engine reliability and life, achieve high gas-liquid mass transfer efficiency, reduce damage, reduce The effect of small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the application of the dynamic wave scrubber to the marine EGR system of the present invention in conjunction with the accompanying drawings, but this should not limit the protection scope of the present invention.

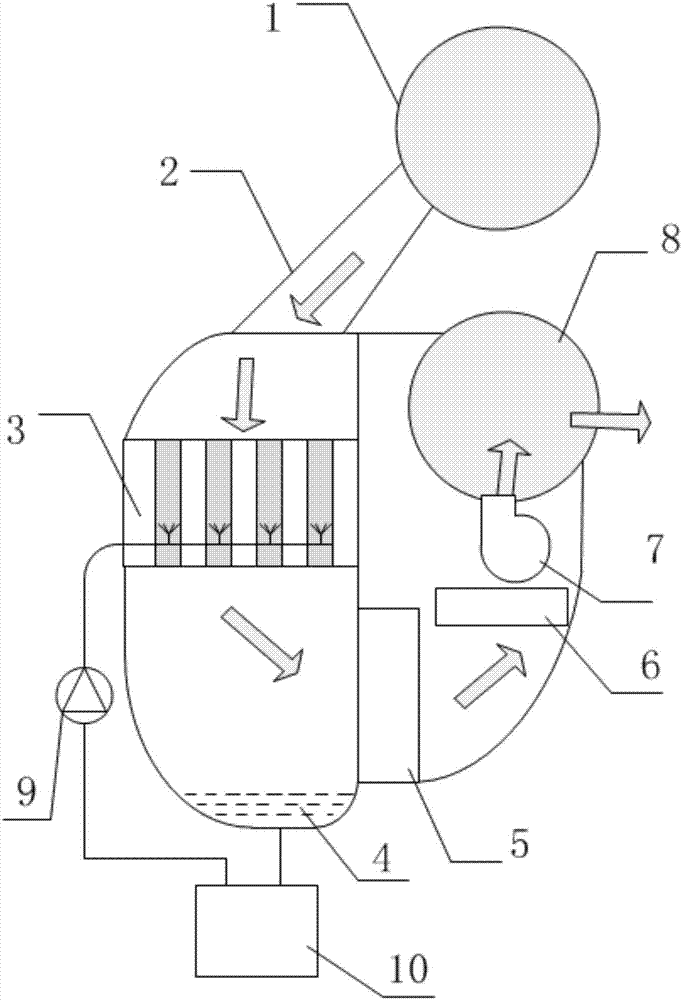

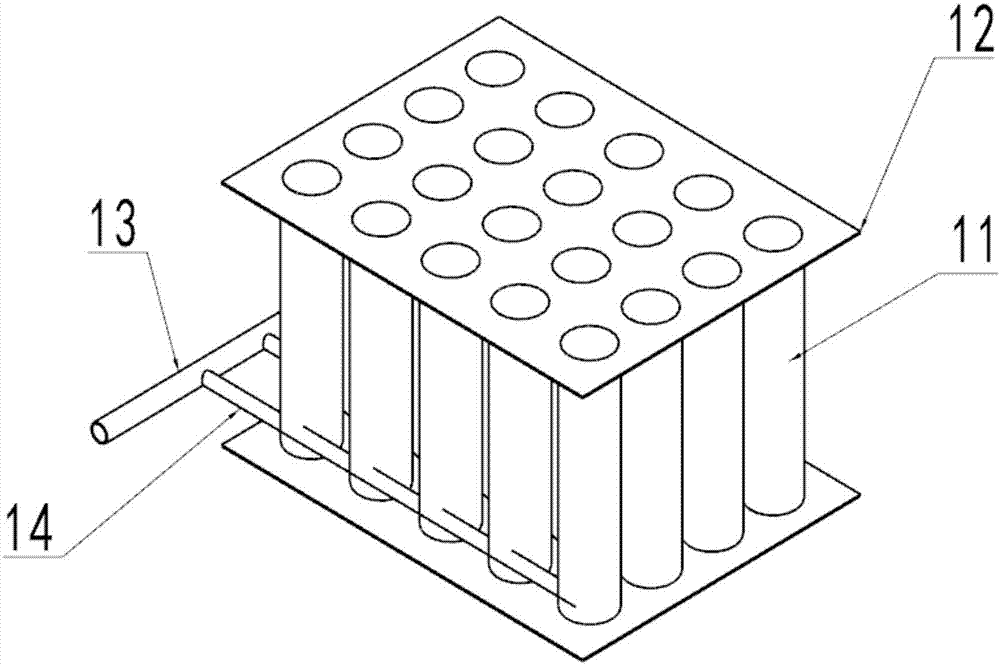

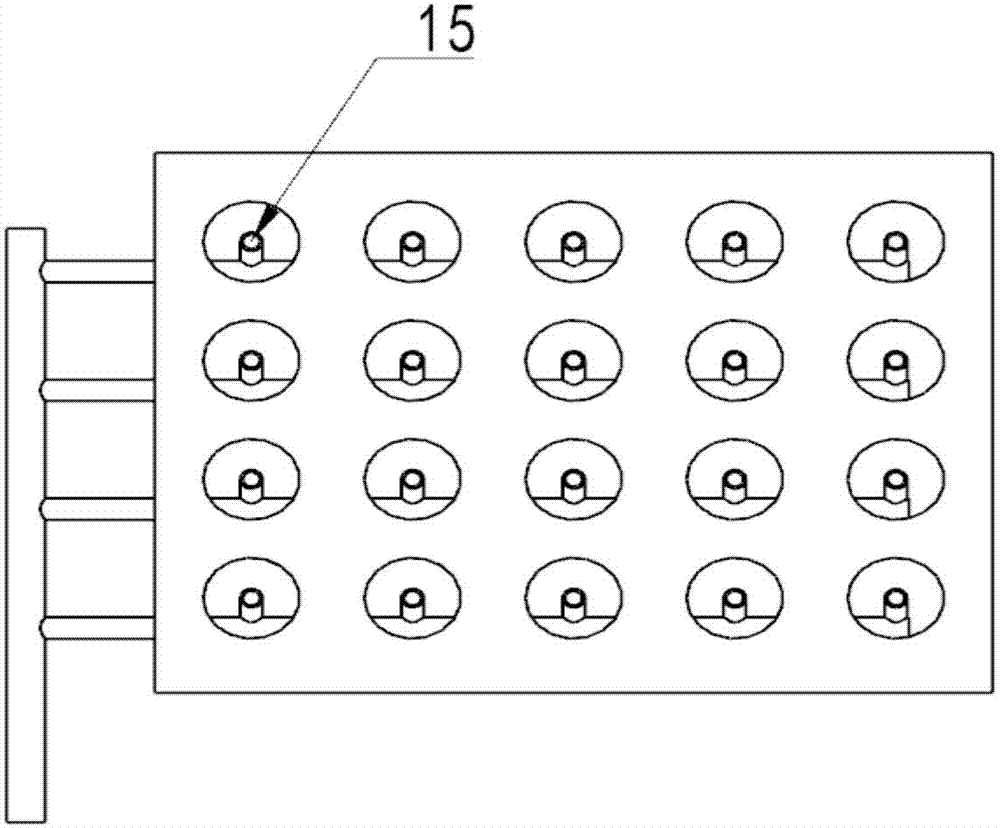

[0032] see Figure 1 ~ Figure 3 , figure 1 It is a structural schematic diagram of the marine diesel engine recirculation exhaust gas system of the present invention, figure 2 Structural outline drawing of special braking power wave scrubber, image 3 It is the top view of the special braking force wave scrubber. As shown in the figure, the special power wave scrubber is arranged after the exhaust header and cone, and before the air cooler;

[0033] It can be seen from the figure that the marine diesel engine exhaust gas recirculation scrubber of the present invention includes a dynamic wave scrubber 3, and the dynamic wave scrubber 3 includes a plurality of reverse nozzle pipes 11 distributed between two plates 12 fixed in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com