Method for measuring mechanical leakage rate of activated carbon bed through gas chromatography

A technology of activated carbon bed, gas chromatography, applied in liquid/vacuum measurement of liquid tightness, by detecting the appearance of fluid at the leak point, etc., to achieve the effect of high capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

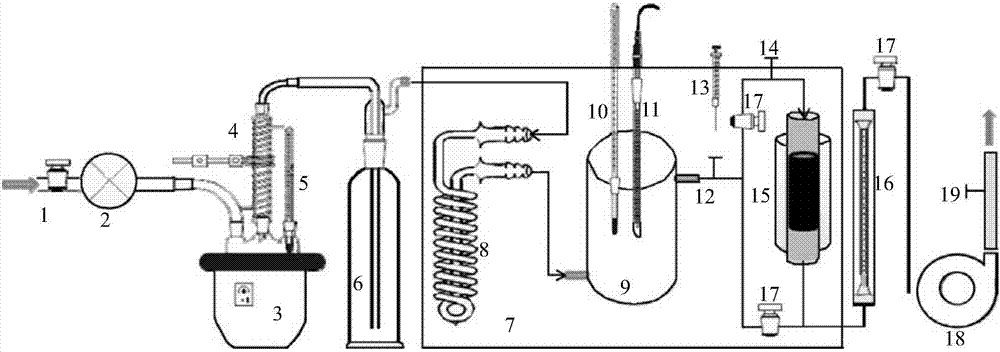

Image

Examples

Embodiment 1

[0031] When there is only one chromatograph, turn on the fan pump, and the thickness of the activated carbon bed is 50mm. When the air flow conditions meet the test requirements, a certain amount of organic gas is injected in the form of wide pulses. The pulse injection immediately starts the upstream and downstream sampling pumps to start upstream and downstream. Sampling, the sample is collected into the sampling bag, the sampling time is 1min, and the sampling volume is 3L. Measure the relative integral area of upstream and downstream sample gas chromatograms respectively, obtain the gas concentration of the sample by loading the standard curve, and calculate the mechanical leakage rate of the activated carbon bed according to the leakage rate formula.

Embodiment 2

[0033] When there are two chromatographs, there is no need for a sampling pump and a sampling bag, and the chromatograph inlet is directly connected to the upstream and downstream sampling ports of the system. When the gas flow conditions meet the test requirements, a certain amount of organic gas is injected in a wide pulse form, and the pulse injection is immediately Turn on the chromatograph to concentrate and inject samples. The sampling time and sample volume are determined according to the actual situation. After the concentration is completed, the chromatograph automatically performs gas chromatographic area integration on the upstream and downstream samples. The gas concentration of the sample is obtained by loading the standard curve, and the activated carbon is calculated according to the leak rate formula. The mechanical leakage rate of the bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com