Simulation method and device for predicting lithium-ion battery material electrochemical performance and equipment

A technology of a lithium ion battery and a simulation method is applied in the simulation field of predicting the electrochemical performance of lithium ion battery materials, which can solve the problems of inability to accurately obtain the influence of the structure, electrochemical and thermodynamic parameters of the lithium ion battery, and achieve accurate prediction and application. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

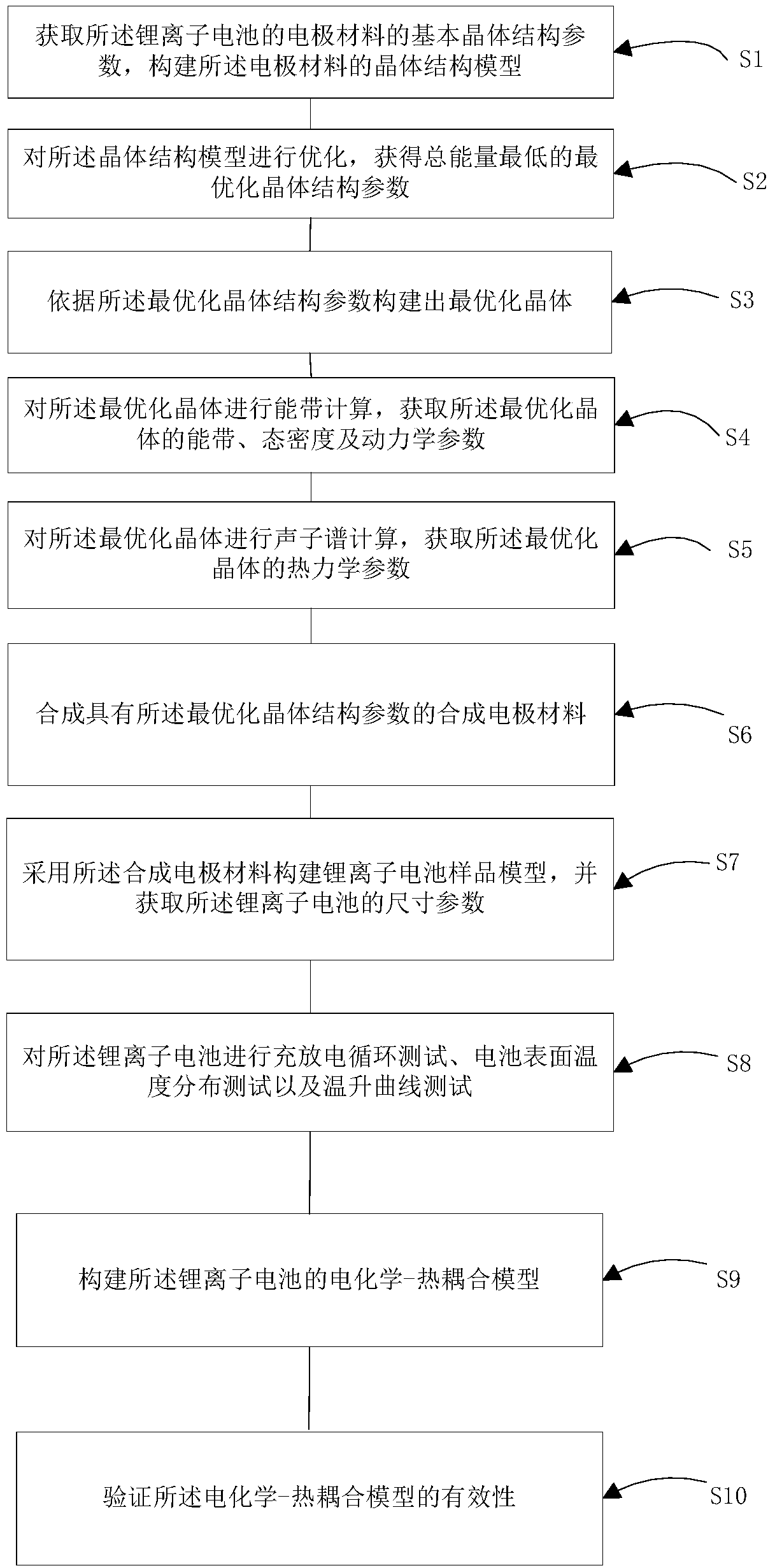

[0068] See figure 1 , an embodiment of the present invention provides a simulation method for predicting the electrochemical performance of a lithium-ion battery material, wherein the method includes:

[0069] S1. Obtain the basic crystal structure parameters of the electrode material of the lithium ion battery, and construct the crystal structure model of the electrode material;

[0070] S2. Optimizing the crystal structure model to obtain the optimal crystal structure parameters with the lowest total energy; based on the adiabatic approximation method, Hartree-Fock self-consistent field approximation method and density functional theory to solve the Kohn-Sham equation of the system , the optimal crystal structure parameters with the lowest total energy are obtained, and the crystal constructed with the optimized crystal structure parameters is used for the next step of calculation.

[0071] S3. Constructing an optimized crystal according to the optimized crystal structure p...

Embodiment 1

[0102] Embodiment 1 of the present invention provides a method for simulating the electrochemical performance of a multi-scale lithium-ion battery material based on first-principles calculation and an electrochemical-thermal coupling model, which mainly includes the following steps:

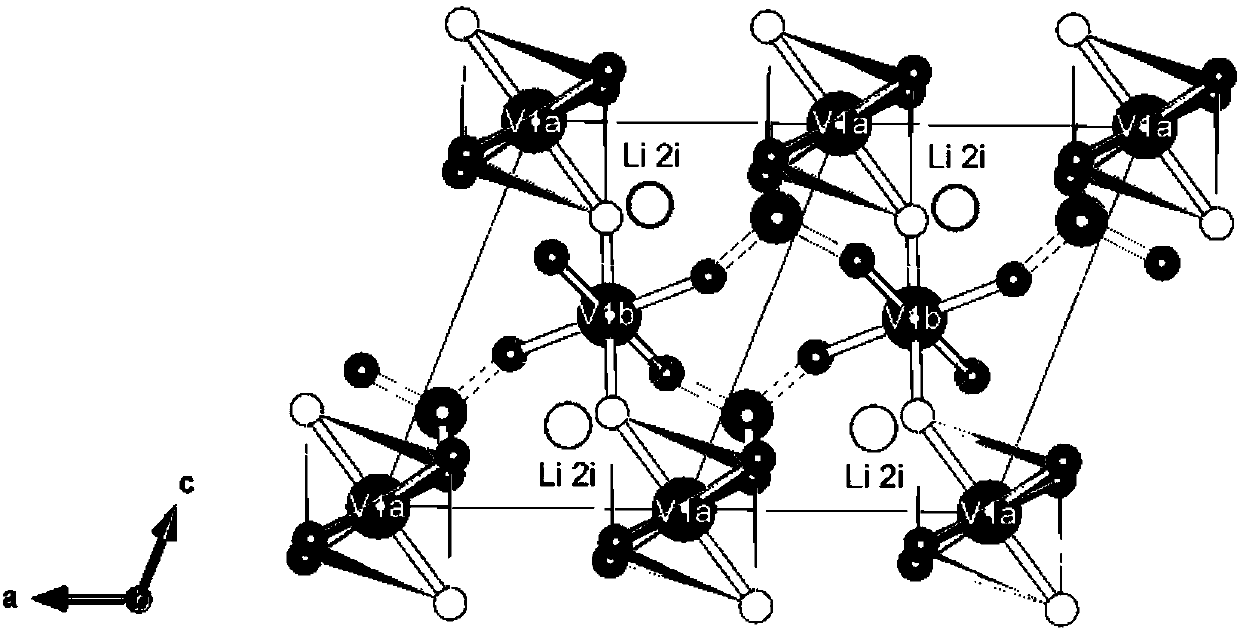

[0103] Obtain the basic crystal structure parameters of the electrode material: firstly, the positive electrode material of lithium vanadium phosphate is used, lithium vanadium phosphate belongs to the triclinic system, and the space group is , the lattice parameters are a=0.53002nm, b=0.72601nm, c=0.51516nm.

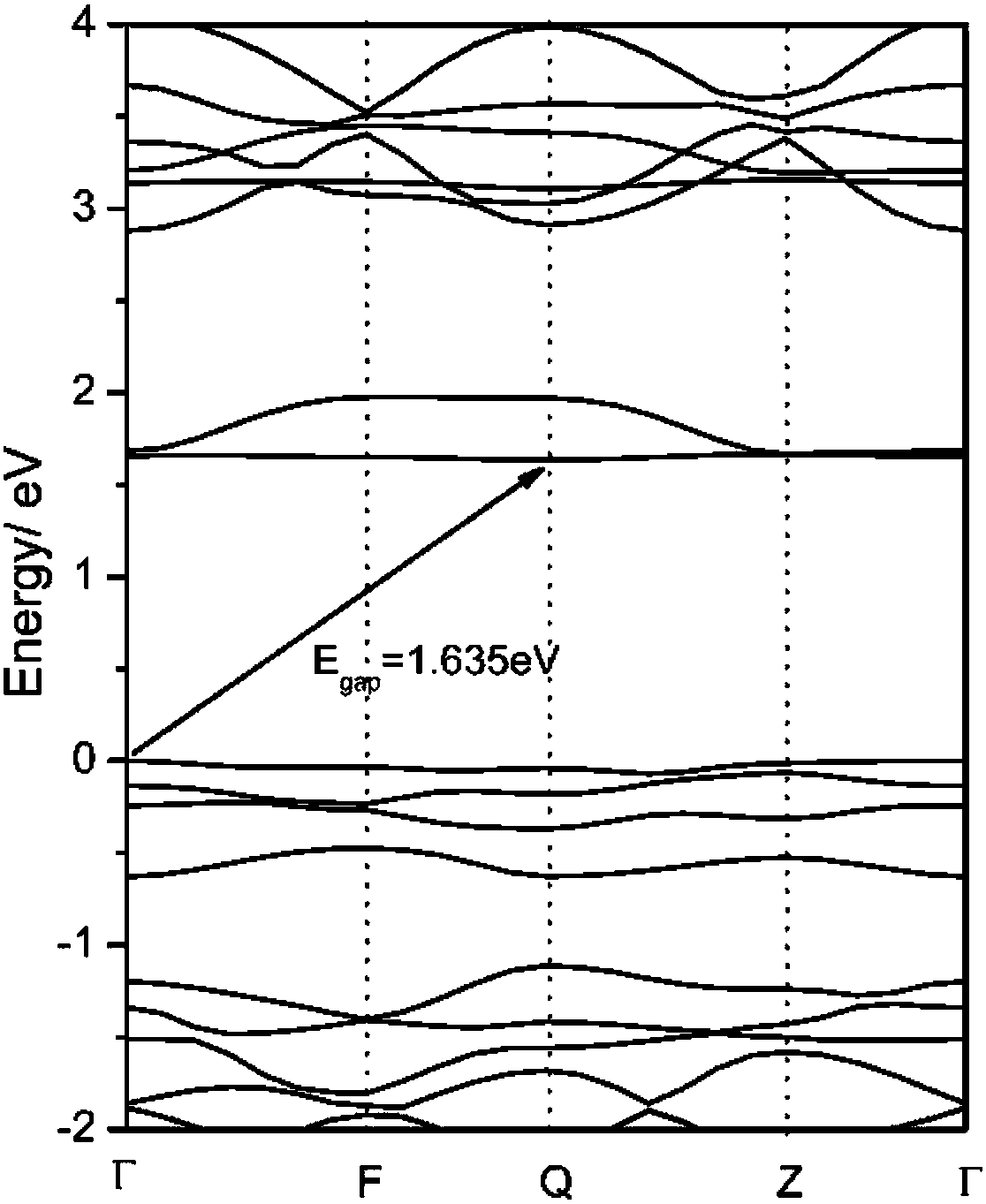

[0104] Structural optimization is carried out on the initial crystal structure model of lithium vanadium phosphate, and the optimal crystal structure parameters with the lowest total energy are obtained; calculations are performed using first-principle calculation software based on density functional theory (DFT), and we also consider spin polarity the exchange-correlation function. The ...

Embodiment 2

[0111] Embodiment 2 of the present invention provides a method for simulating the electrochemical performance of multi-scale lithium-ion battery materials based on first-principle calculations and electrochemical-thermal coupling models, including the following steps:

[0112] Obtain the basic crystal structure parameters of the electrode material: firstly, the positive electrode material of lithium vanadium phosphate is used, lithium vanadium phosphate belongs to the triclinic system, and the space group is , the lattice parameters are a=0.53002nm, b=0.72601nm, c=0.51516nm.

[0113] The structure optimization of the initial crystal structure model of molybdenum disulfide-coated lithium vanadium phosphate was carried out using first-principles calculation software based on density functional theory (DFT), and we also considered the exchange correlation function of spin polarization. The ultrasoft pseudopotential proposed by Vanderbilt is used to describe the ion-electron int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com