Polycrystalline black silicon wafer diffusion method through MCCE etching

A diffusion method, black silicon technology, applied in the field of solar cells, can solve the problems of difficult diffusion, poor square resistance uniformity, easy burn-through, etc., and achieve good electrical properties, good uniformity, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

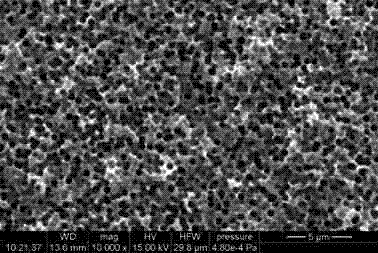

Image

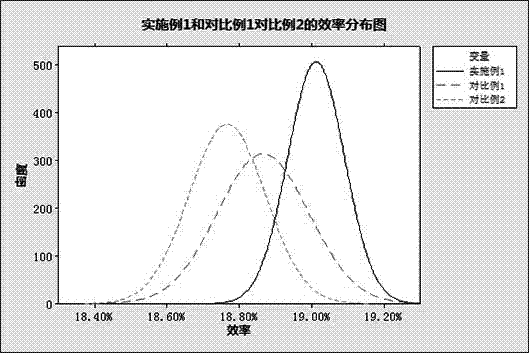

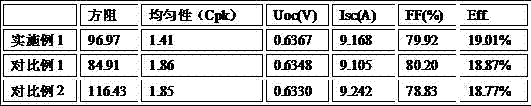

Examples

Embodiment 1

[0023] Example 1: An MCCE texturing polycrystalline black silicon wafer diffusion method, which is suitable for the black silicon diffusion process prepared by metal-catalyzed chemical etching:

[0024] In the first deposition process, the nitrogen flow rate of the phosphorus source is 600~800 sccm, the large nitrogen flow rate is 13.9slm, the oxygen flow rate is 1300 sccm, the temperature is 795 °C, and the deposition treatment time is 600s~700s;

[0025] In the first advancing process, the nitrogen flow of the phosphorus source is 0 sccm, the large nitrogen flow is 16 slm, the oxygen flow is 0 sccm, the temperature is 832 °C, and the advancing treatment time is 500s~600s;

[0026] In the second deposition process, the nitrogen flow rate of the phosphorus source is 1500~1700 sccm, the large nitrogen flow rate is 12.5 slm, the oxygen flow rate is 1900 sccm, the temperature is 832 °C, and the deposition treatment time is 300s~400s;

[0027] In the second advancing process, the nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com