Heavy metal wastewater treatment system and method

A wastewater treatment system and heavy metal technology, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of high power consumption, high energy consumption, difficulty in compliance, etc., and achieve reliable operation. , high degree of automation, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

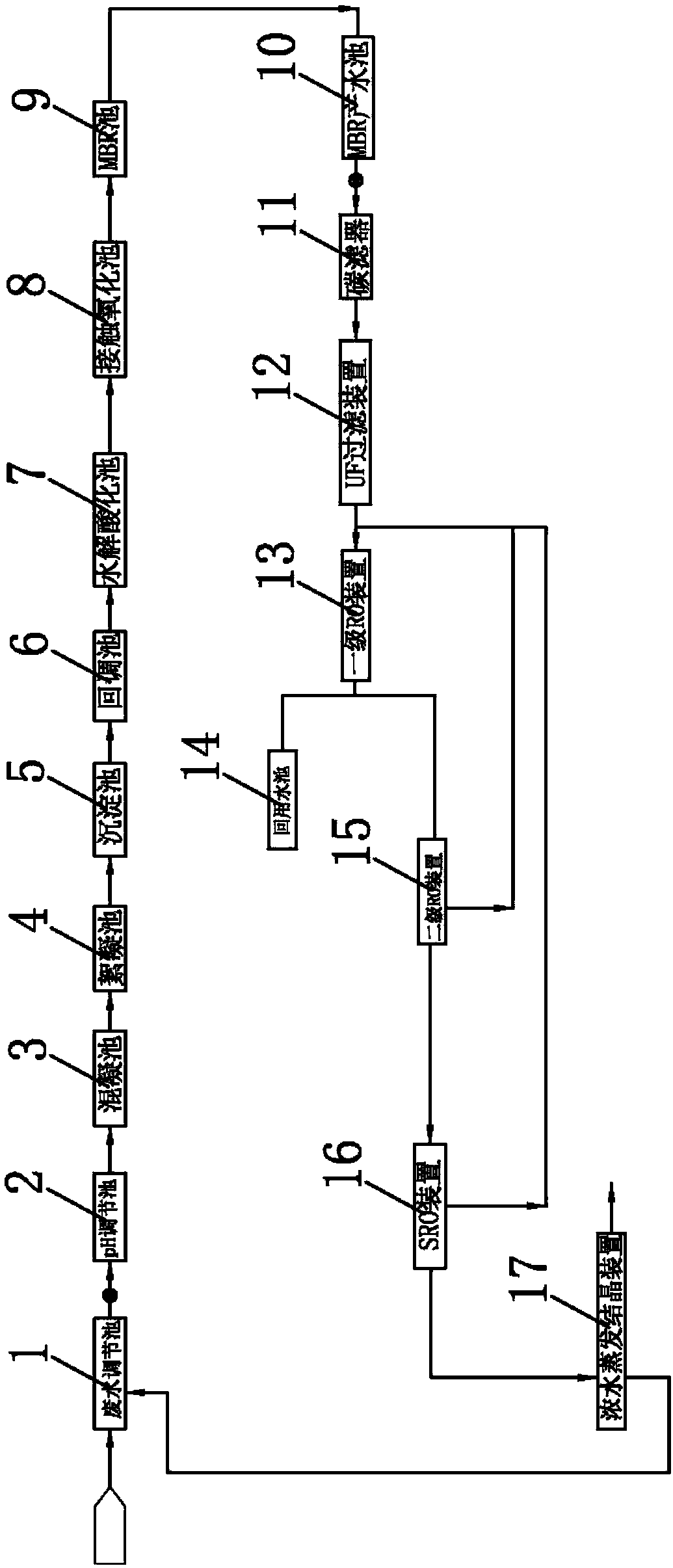

[0026] Such as figure 1 As shown, a heavy metal wastewater treatment system includes a pH adjustment tank 2, a coagulation tank 3, a flocculation tank 4, a sedimentation tank 5, a biochemical treatment system, an ultrafiltration system, a reverse osmosis system, and evaporation, concentration and crystallization that are connected in sequence according to the wastewater flow direction. Device 17, the reverse osmosis system includes a primary RO device 13 and a multi-stage RO system arranged according to the flow direction of waste water, the primary RO system is provided with a first purified water outlet and a first concentrated water outlet, and the first purified water The water outlet is connected with a reused water tank 14, and the first concentrated water outlet is connected with the multi-stage RO system.

[0027] Wherein, the multi-stage RO system includes a secondary RO device 15 and an SRO device 16 connected in sequence according to the flow direction of the waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com