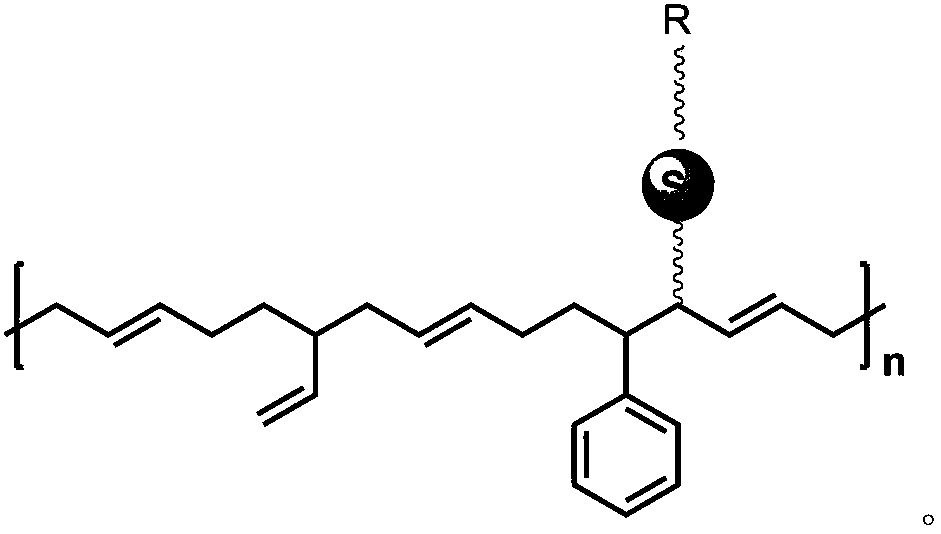

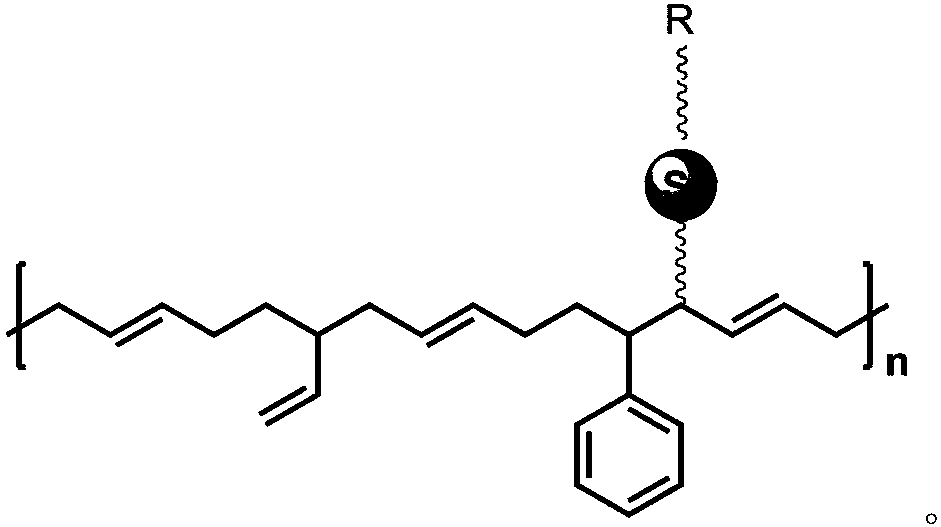

Functional SSBR (solution polymerized styrene-butadiene rubber) in silane coupling agent modification chain and synthesis method of functional SSBR

A technology of solution-polymerized styrene-butadiene rubber and silane coupling agent, applied in the field of solution-polymerized styrene-butadiene rubber synthesis, can solve the problems of affecting the reinforcement effect, high production cost, limited functional group content, etc., and achieves improved functionalization efficiency and improved processing. Performance, improve the effect of blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

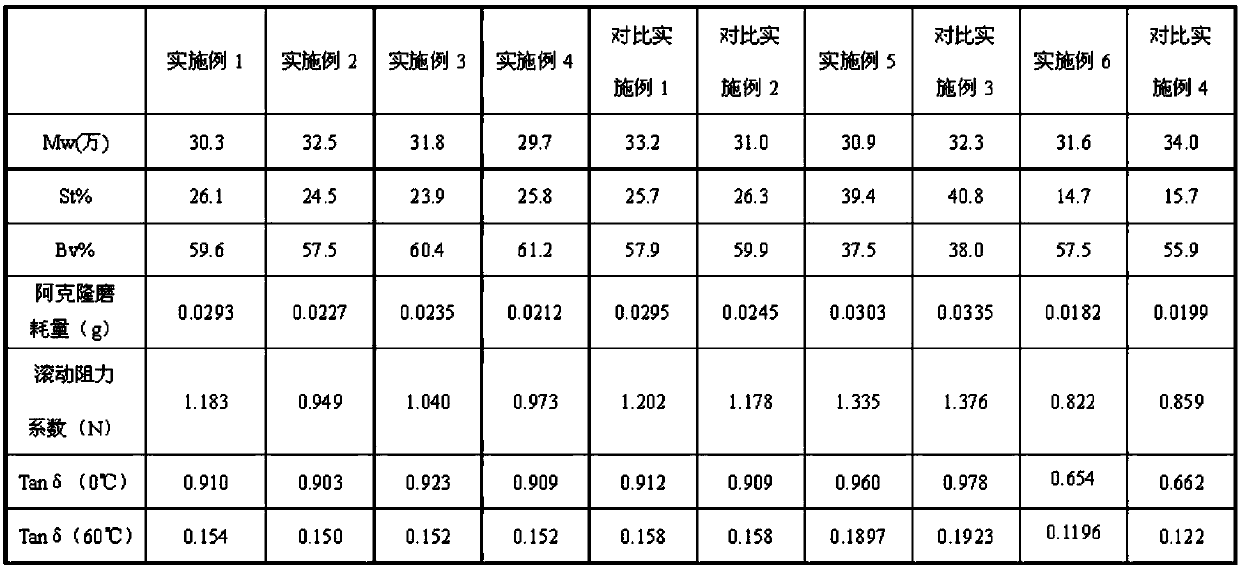

Embodiment 1

[0027] In a jacketed 15L polymerization kettle, the system was replaced with argon for 3 times. Add 10.8 L of cyclopentane, 315 g of styrene, 945 g of butadiene, and 3.1 g of ethyl tetrahydrofurfuryl ether into the polymerization kettle. After removing impurities, raise the temperature to 40°C, add 4.2 mmol of n-butyllithium, and polymerize at natural temperature. After 1 hour, add 3mmol of n-butyllithium, keep at 40°C, stir for 10 minutes, then add 3.6mmol of 3-chloropropyltrimethoxysilane, react for 2 hours, terminate the reaction, add 1010 6.3g of antioxidant, and discharge , the glue is coagulated by wet method and dried.

Embodiment 2

[0029] In a jacketed 15L polymerization kettle, the system was replaced with argon for 3 times. Add 10.8 L of cyclopentane, 315 g of styrene, 945 g of butadiene, and 3.1 g of ethyl tetrahydrofurfuryl ether into the polymerization kettle. After removing impurities, raise the temperature to 40°C, add 4.2 mmol of n-butyllithium, and polymerize at natural temperature. After 1 hour, add 150mmol n-butyllithium, keep at 40°C, stir for 10 minutes, add 180mmol 3-chloropropyltrimethoxysilane, react for 1.5 hours, stop the reaction, add 1010 63g of antioxidant, discharge, glue The liquid is condensed by wet method and dried.

Embodiment 3

[0031] In a jacketed 15L polymerization kettle, the system was replaced with argon for 3 times. Add 10.8 L of cyclopentane, 315 g of styrene, 945 g of butadiene, and 3.1 g of ethyl tetrahydrofurfuryl ether into the polymerization kettle. After removing impurities, raise the temperature to 40°C, add 4.2 mmol of n-butyllithium, and polymerize at natural temperature. After 1 hour, add 30mmol n-butyllithium, keep at 40°C, stir for 10 minutes, add 36mmol 3-chloropropyltrimethoxysilane, react for 1.5 hours, stop the reaction, add antioxidant 1010 63g, discharge, glue The liquid is condensed by wet method and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com