Heat treatment method of fatigue-damage-resisting aviation skin Al-Cu-Mg T3 aluminum alloy

A technology of al-cu-mgt3, heat treatment method, applied in the field of heat treatment of Al-Cu-MgT3 aluminum alloy for fatigue damage-resistant aviation skin, can solve the complex fatigue behavior of aluminum alloy, the gap in fatigue damage resistance, increase the content, etc. problem, to slow down the recrystallization process, eliminate harmful texture, and improve fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

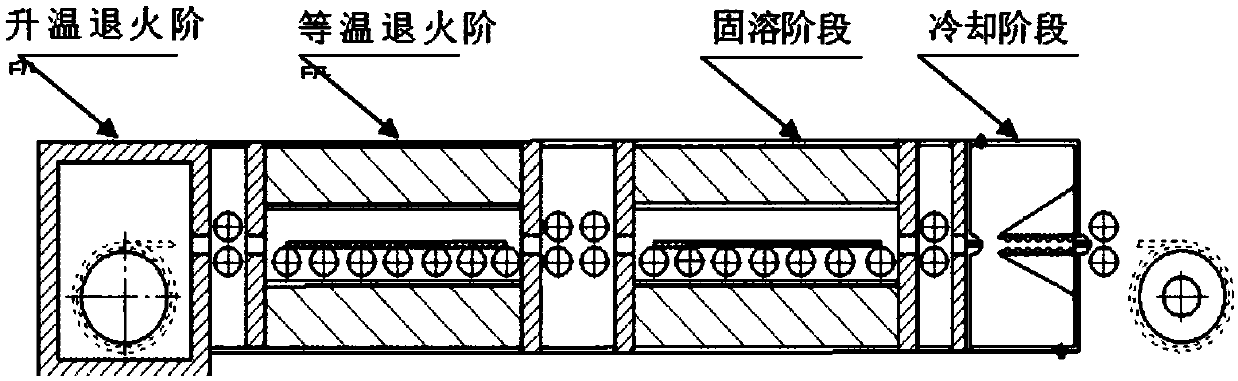

[0020] Put the roll-shaped material with a total length of 10m into the heating annealing furnace, then raise the temperature inside the heating annealing furnace to 280°C at a heating rate of 2K / s, and then send it in at an unwinding speed of 1m / s In the isothermal annealing furnace, the plate that enters the isothermal annealing furnace after the temperature rise annealing is stagnant in the isothermal annealing furnace with a temperature of 300 °C for 40 minutes, and then transferred to the solid solution furnace at a speed of 0.25 m / s; after isothermal After annealing, the plate that enters the solid solution furnace is stagnant in the solid solution furnace with a temperature of 515°C for 5 minutes, and then transported to the cooling room at a speed of 5m / s, and quenched by circulating room temperature water, and the quenching time is 4s. Then take it out and roll it up to get the final Al-Cu-Mg T3 plate sample, the fatigue crack growth rate is: da / dN=1.83×10 -3 mm / cycle...

Embodiment 2

[0022] Put the roll-shaped material with a total length of 30m into the heating annealing furnace, then raise the temperature inside the heating annealing furnace to 400°C at a heating rate of 0.5K / s, and then unwind and convey at a speed of 0.25m / s After being sent into the isothermal annealing furnace, the plate that enters the isothermal annealing furnace after the temperature rise annealing is stagnated in the isothermal annealing furnace with an inner temperature of 400°C for 20 minutes, and then transferred to the solid solution furnace at a speed of 1m / s; After isothermal annealing, the plates entering the solid solution furnace stagnate for 120 minutes in the solid solution furnace at a furnace temperature of 495 ° C, and then are transported to the cooling room at a speed of 0.25 m / s, and are quenched by circulating room temperature water. The quenching time is After 7s, it was taken out and rolled up to obtain the final Al-Cu-Mg T3 plate sample, and its fatigue perfor...

Embodiment 3

[0024] Put the roll-shaped material with a total length of 20m into the heating annealing furnace, then raise the temperature inside the heating annealing furnace to 320°C at a heating rate of 1K / s, and then send it to the After entering the isothermal annealing furnace, the plates entering the isothermal annealing furnace after the temperature rise annealing are stagnant in the isothermal annealing furnace with a temperature of 350 ° C for 30 minutes, and then transferred to the solid solution furnace at a speed of 0.6 m / s; After isothermal annealing, the plate entering the solid solution furnace is stagnant in the solid solution furnace with a temperature of 500 ° C for 60 minutes, and then transported to the cooling room at a speed of 3 m / s, and quenched by circulating room temperature water, and the quenching time is 6 s , then take it out and roll it up to get the final Al-Cu-Mg T3 plate sample, the fatigue performance is: da / dN=1.36×10 -3 mm / cycle, ΔK=30MPa.m 1 / 2 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com