Manufacture method of electrode, TFT (Thin Film Transistor) and manufacture method thereof and related substrate

A technology for thin film transistors and manufacturing methods, applied in the fields of array substrates, electrode manufacturing methods, thin film transistors and their manufacturing methods, and display devices, capable of solving problems such as low etching efficiency, complicated processes, and material waste, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

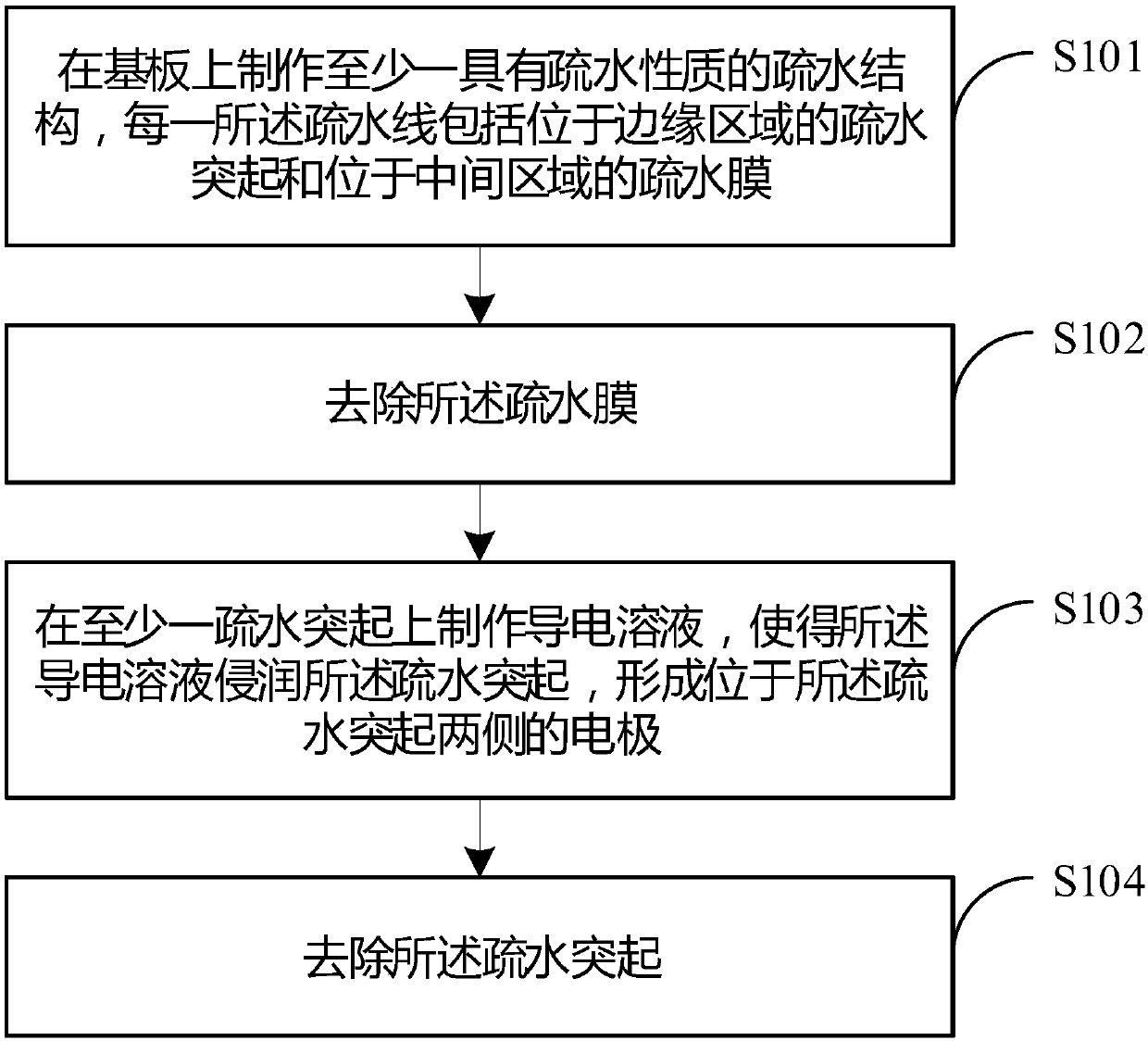

[0096] The fabrication of short-channel inorganic semiconductor thin film transistors with a bottom-gate and top-contact structure will be described in detail below.

[0097] Such as Figure 9 As shown, the grid 220 is first fabricated on the substrate 100. The material of the grid 220 is metal or conductive oxide. The grid 220 can be fabricated by sputtering, evaporation, solution coating or printing. The specific details of the grid 220 The manufacturing method is similar to the prior art, and will not be repeated here.

[0098] Next, a gate insulating layer 230 is formed on the gate 220. The gate insulating layer 230 is a composition of a single-layer oxide or a multi-layer oxide. The gate insulating layer 230 can be formed by anodic oxidation, sputtering, solution coating or The specific manufacturing method of the gate insulating layer 230 is similar to that of the prior art, and will not be repeated here.

[0099] Next, fabricate an inorganic semiconductor active layer...

Embodiment 2

[0103] The fabrication of short-channel inorganic semiconductor thin film transistors with a bottom-gate and bottom-contact structure will be described in detail below.

[0104] Such as Figure 10 As shown, firstly, the gate 220 and the gate insulating layer 230 are sequentially fabricated on the substrate 100. The specific fabrication methods of the gate 220 and the gate insulating layer 230 are the same as those in Embodiment 1, and will not be repeated here.

[0105] Next, fabricate the source electrode 250a and the drain electrode 250b on the gate insulating layer 230. The specific fabricating method of the source electrode 250a and the drain electrode 250b adopts the above-mentioned electrode fabricating method provided in the specific embodiment of the present invention, and specifically includes:

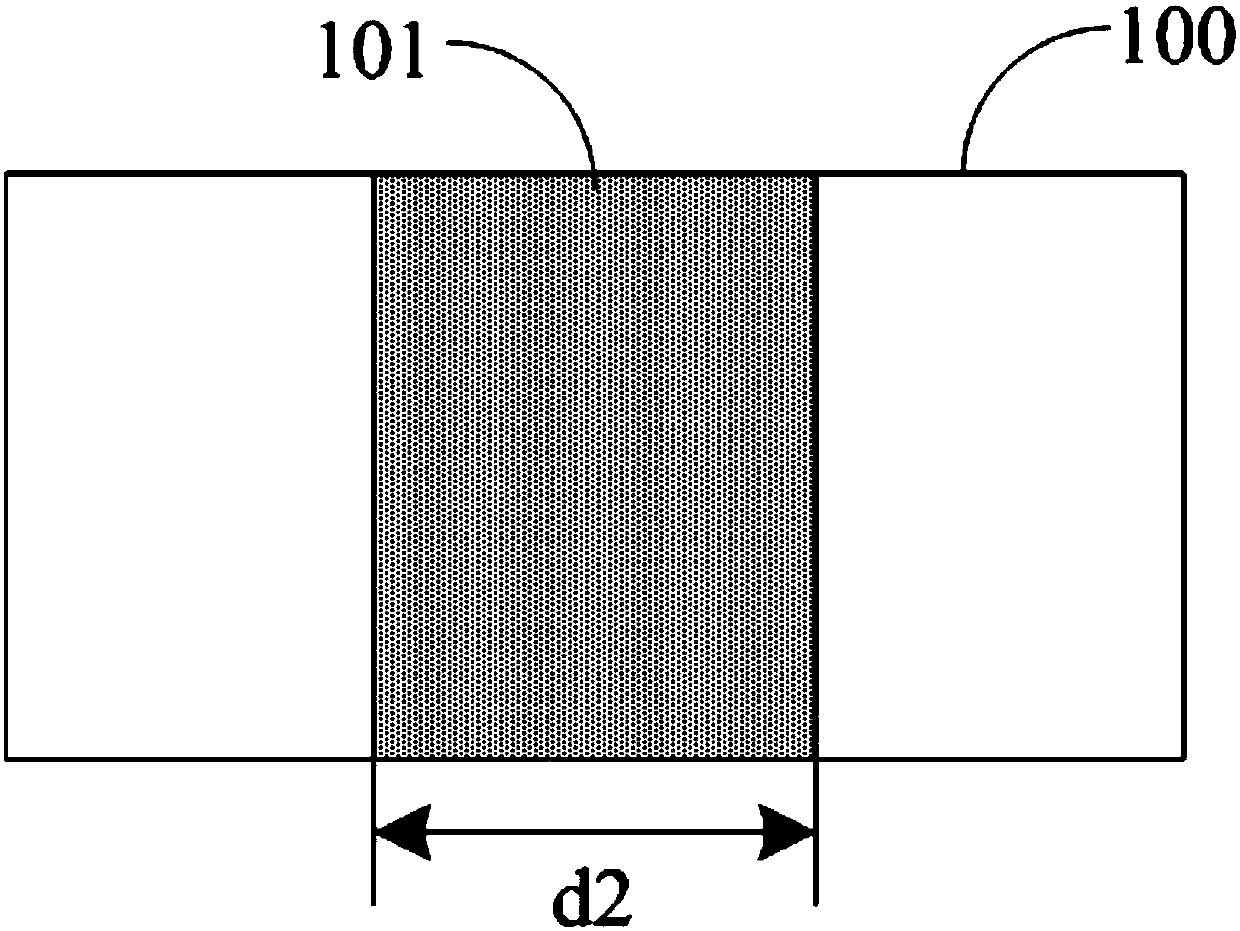

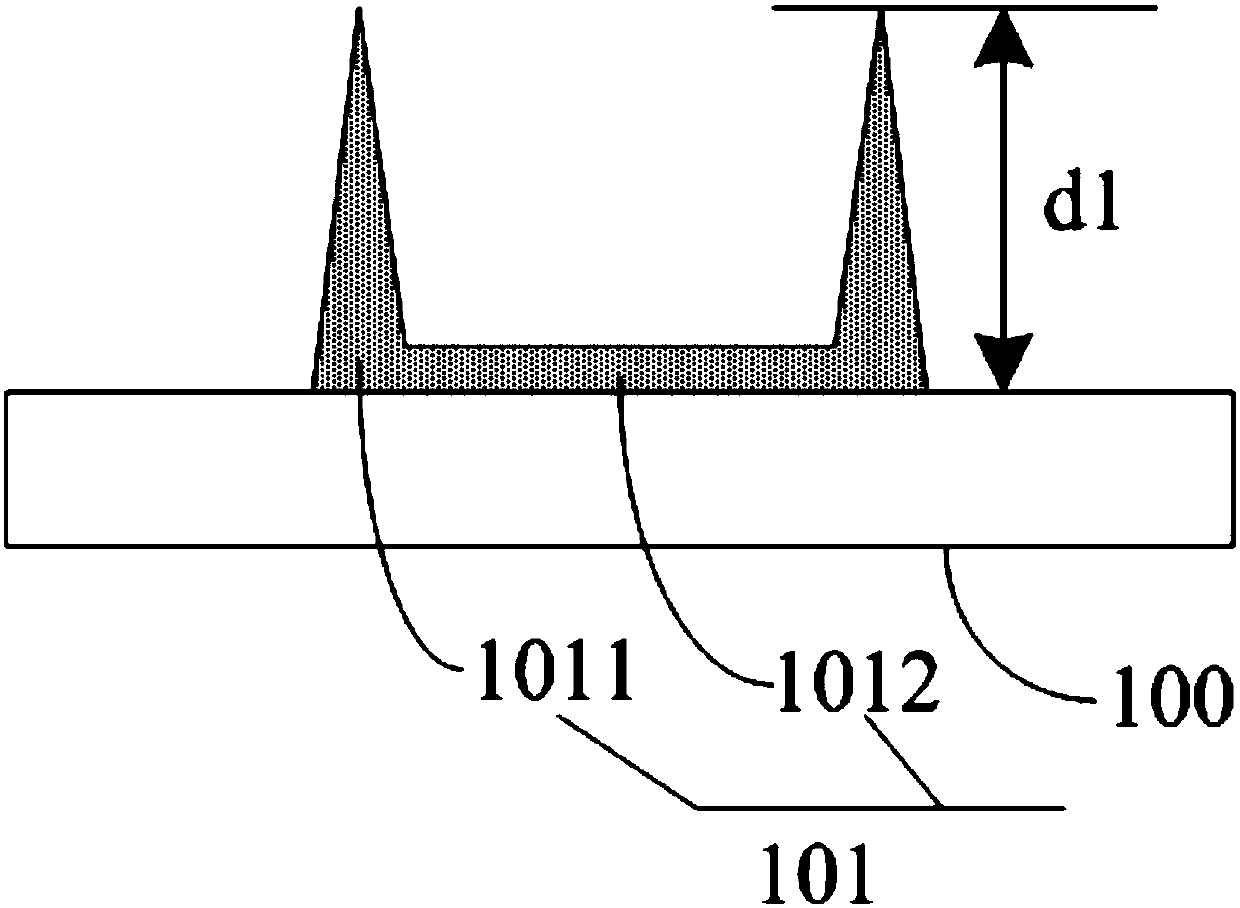

[0106] Firstly, a perfluororesin with hydrophobic properties is printed on the grid insulating layer 230 by inkjet printing, and the printed perfluororesin spontaneously form...

Embodiment 3

[0109] The fabrication of short-channel inorganic semiconductor thin film transistors with a top-gate and top-contact structure will be described in detail below.

[0110] Such as Figure 11 As shown, firstly, the inorganic semiconductor active layer 240 is fabricated on the substrate 100. The specific fabrication method of the inorganic semiconductor active layer 240 is the same as the fabrication method of Embodiment 1, and will not be repeated here.

[0111] Next, the source electrode 250a and the drain electrode 250b are manufactured on the inorganic semiconductor active layer 240. The specific manufacturing method of the source electrode 250a and the drain electrode 250b is the same as that of Embodiment 1, and will not be repeated here. The formed source electrode 250a The channel length d8 between the channel and the drain 250b does not exceed 5 μm.

[0112] Next, a gate insulating layer 230 and a gate 220 are fabricated sequentially on the source 250a and the drain 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com