Co-doped ZnO gas-sensitive nano-material preparation method, product of nano-material and application of nano-material

A nano-material and gas-sensing technology, which is applied in the field of metal oxide nano-material preparation, can solve the problems of high working temperature and poor selectivity, and achieve the effect of simple preparation method, strong controllability, and improved selectivity and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

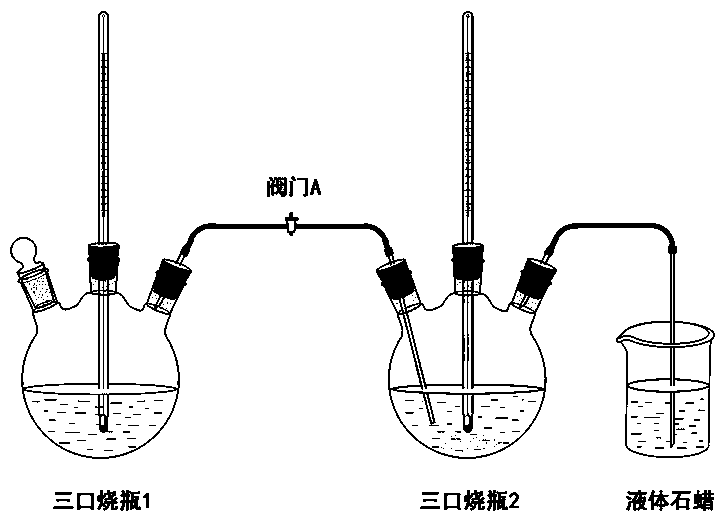

[0025] (1) Take 20g of ammonium bicarbonate and place it in the three-necked flask 1, and add 50mL of water;

[0026] (2) Weigh 0.4g of zinc acetate and 0.005g of cobalt chloride hexahydrate and place it in a three-necked flask 2, and add 50mL of water;

[0027] (3) After heating the three-necked flask from 2 to 80°C, heat the three-necked flask from 1 to 80°C, and pass the generated gas into the solution of the three-necked flask 2, and react for 30 minutes; filter the precipitate, wash and dry, and wait until the drying is completed , and then placed in a muffle furnace, fired at 500° C. for 180 min to obtain Co-doped ZnO gas-sensitive nanomaterials.

[0028] figure 1 It is a diagram of the reaction device for preparing Co-doped ZnO gas-sensitive nanomaterials in the present invention. The ammonium bicarbonate in the three-necked flask 1 is thermally decomposed to produce ammonia and carbon dioxide gas, and the generated gas is passed into the three-necked flask 2 through t...

Embodiment 2

[0030] (1) Take 25g of ammonium bicarbonate and place it in a three-necked flask 1, and add 50mL of water;

[0031] (2) Weigh 0.5g of zinc acetate and 0.006g of cobalt chloride hexahydrate and place it in a three-necked flask 2, and add 50mL of water;

[0032] (3) After heating the three-necked flask from 2 to 90°C, heat the three-necked flask from 1 to 80°C, and pass the generated gas into the solution of the three-necked flask 2, and react for 40 minutes; filter the precipitate, wash and dry, and wait until the drying is completed , and then placed in a muffle furnace, fired at 450° C. for 150 min to obtain Co-doped ZnO gas-sensitive nanomaterials.

Embodiment 3

[0034] (1) Take 23g of ammonium bicarbonate and place it in a three-necked flask 1, and add 50mL of water;

[0035] (2) Weigh 0.6g of zinc acetate and 0.006g of cobalt chloride hexahydrate and place it in a three-necked flask 2, and add 50mL of water;

[0036] (3) After heating the three-necked flask from 2 to 70°C, heat the three-necked flask from 1 to 60°C, and pass the generated gas into the solution of the three-necked flask 2, and react for 40 minutes; filter the precipitate, wash and dry, and wait until the drying is completed , and then placed in a muffle furnace, fired at 550° C. for 120 min to obtain Co-doped ZnO gas-sensitive nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com