Cassava essence, preparation method thereof and application thereof to cigarette

A technology of potato essence and cassava, which is applied in the field of preparation and application of natural spices, and achieves the effects of simple process, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

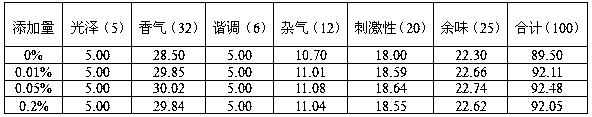

Examples

Embodiment 1

[0025] A preparation method of cassava essence, which comprises the following steps:

[0026] (1) Crushing and beating: Select mature cassava with high sugar content and high juice yield, cut the cassava pulp into slices with a thickness of 5-6 mm with a knife, and beat the cassava slices with a high-speed tissue masher for 2 minutes at a speed of 11,000 rpm. get cassava pulp;

[0027] (2) Filtration under reduced pressure: filter the obtained cassava pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0028] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 45°C and 55KPa to obtain concentrated cassava juice, and the dry matter content in the concentrated cassava juice is 30%;

[0029] (4) Maillard reaction: Add 30g of cassava concentrated juice, 10g of maltose, 10g of proline and 400g of propylene glycol in a 1000ml three-neck flask equipped with a reflux tube and a stirrer, heat in an oil bath at 120°C f...

Embodiment 2

[0041] A preparation method of cassava essence, which comprises the following steps:

[0042] (1) Crushing and beating: Select mature cassava with high sugar content and high juice yield, cut the cassava pulp into slices with a thickness of 5-6 mm with a knife, and beat the cassava slices with a high-speed tissue masher for 15 minutes at a speed of 12000 rpm. get cassava pulp;

[0043] (2) Filtration under reduced pressure: filter the obtained cassava pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0044] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 60°C and 65KPa to obtain concentrated cassava juice, and the dry matter content in the concentrated cassava juice is 25%;

[0045] (4) Maillard reaction: Add 40g of cassava concentrated juice, 10g of honey, 10g of glycine and 400g of propylene glycol to a 1000ml three-neck flask equipped with a reflux tube and a stirrer, heat in an oil bath at 150°C for...

Embodiment 3

[0054] A preparation method of cassava essence, which comprises the following steps:

[0055] (1) Crushing and beating: Select mature cassava with high sugar content and high juice yield, cut the cassava pulp into slices with a thickness of 5-6 mm with a knife, and beat the cassava slices with a high-speed tissue masher for 20 minutes at a speed of 10,000 rpm. get cassava pulp;

[0056] (2) Filtration under reduced pressure: filter the obtained cassava pulp under reduced pressure with a Buchner funnel, and collect the filtrate;

[0057] (3) Concentration under reduced pressure: Concentrate the filtrate under reduced pressure at 40°C and 70KPa to obtain concentrated cassava juice. The dry matter content in the concentrated cassava juice is 35%;

[0058] (4) Maillard reaction: Add 30g cassava juice concentrate, 10g malt extract, 5g alanine and 350g propylene glycol to a 1000ml three-necked flask equipped with a reflux tube and a stirrer, heat in an oil bath at 170°C for 1 hour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com