Tailing in-situ leaching process and system

A tailings and leaching technology, applied in the direction of improving process efficiency, can solve problems such as resource loss and waste, and achieve the effects of diverse selection, effective blocking and monitoring, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not as limitations of the present invention.

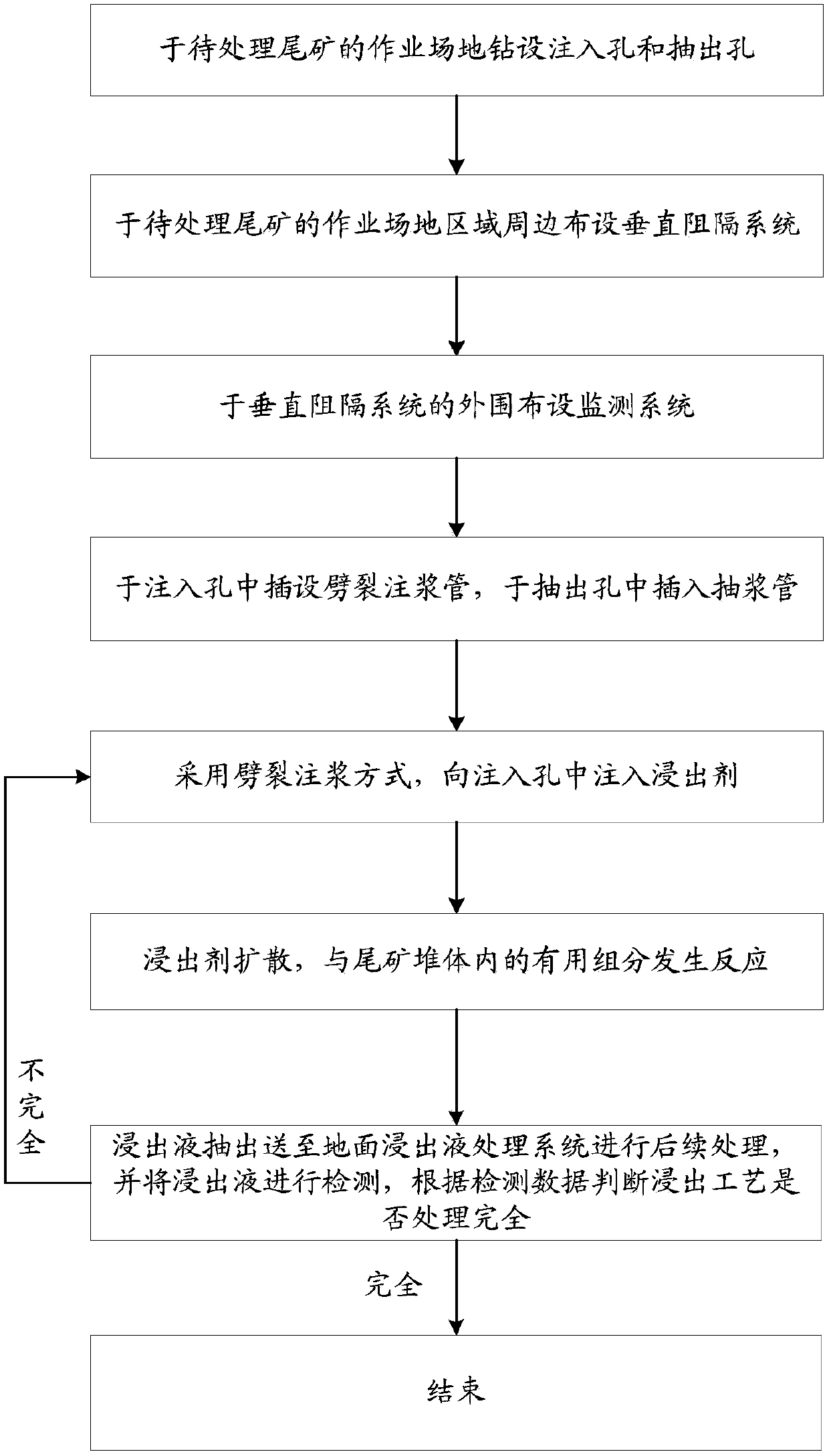

[0039] The invention provides a tailings in-situ leaching process, such as figure 1 shown, including the following processes:

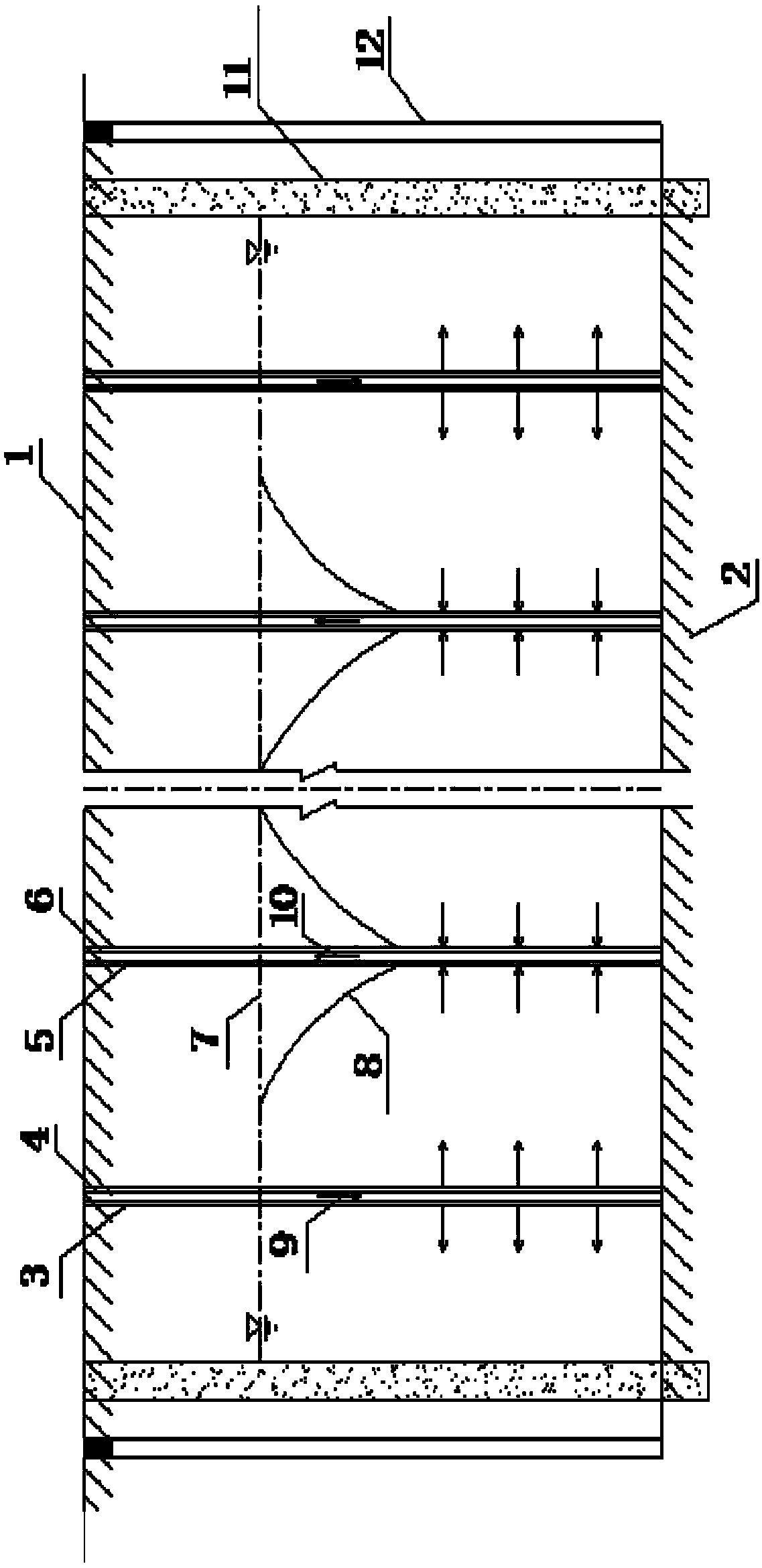

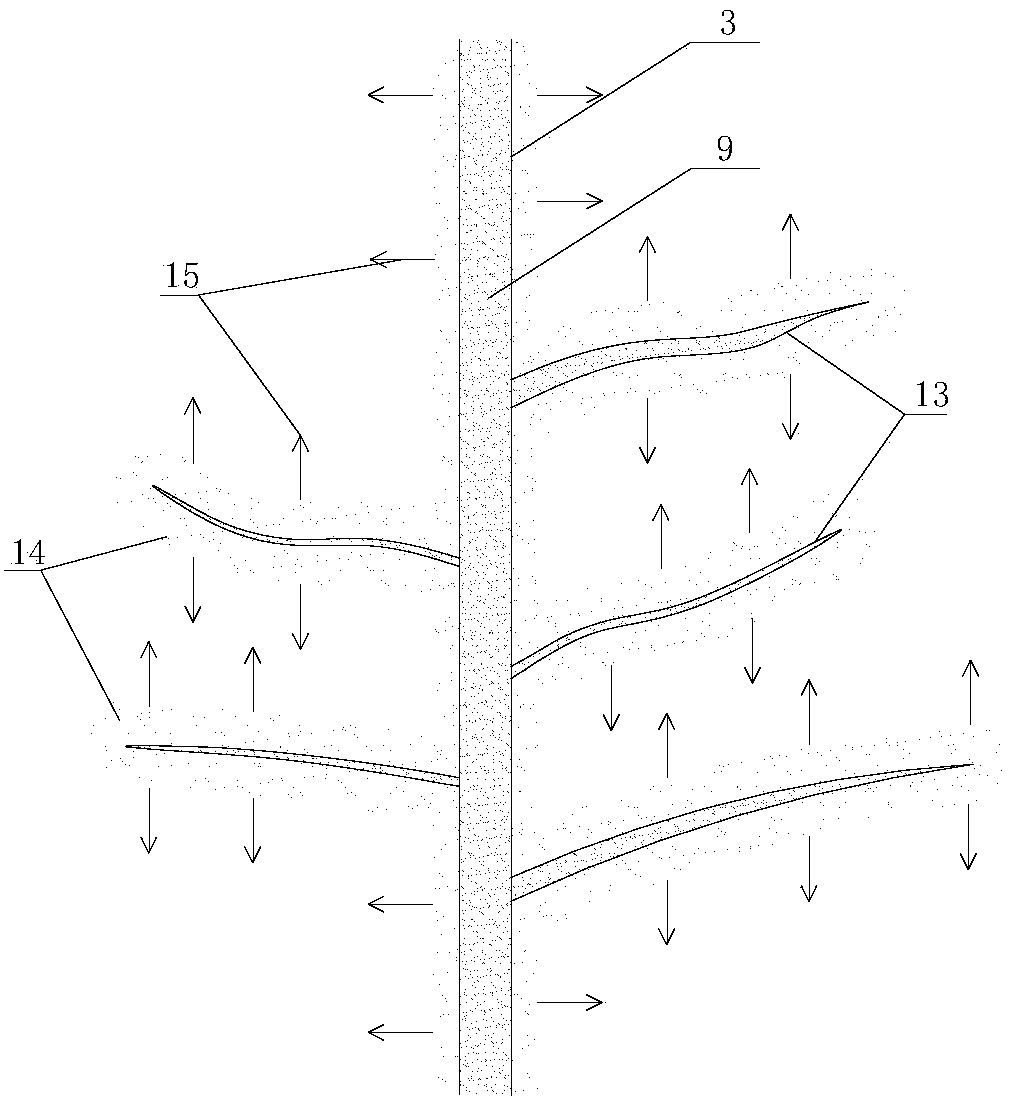

[0040] Step 1: Use the drilling rig 16 to drill down multiple injection holes 3 and extraction holes 5 on the ground 1 of the working site where the tailings are to be treated. The crack test is determined; the injection hole 3 and the extraction hole 5 are uniformly arranged, and the injection hole 3 and the extraction hole 5 are also uniformly arranged with each other, preferably, as image 3 The grid distribution shown or the determinant distribution is laid out. The depths of the injection hole 3 and the extraction hole 5 meet the setting of the depth of the tailing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com