Preparation method of high-specific-surface-area ribbon-shaped graphite

A high specific surface area, band-shaped technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as the influence of electrode energy density and power density, reduce application effect, and damage to graphite crystallites. Inexpensive, high graphitic performance, effect of high and medium porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare a kind of ribbon-shaped graphite with high specific surface area according to the following steps:

[0033] (1) Dissolve 2g of petroleum asphalt in 10 ml of tetrahydrofuran to obtain solution A; add 8 ml of tetraethyl orthosilicate, 1.5 ml of deionized water and 0.8 ml of HF into a stainless steel cup, and stir magnetically at room temperature to form a uniform and transparent Solution B; add solution A to solution B, stir, stir evenly, transfer to a polytetrafluoroethylene reaction tank, and stand at 50°C until petroleum pitch / silicone gel is formed;

[0034] (2) Dry the gel obtained in step (1) at 100 °C, and then pre-oxidize it in an air atmosphere at 250 °C for 12 hours to obtain a pitch / silica composite; put the pitch / silica composite into Carbonization furnace, under the protection of nitrogen atmosphere, the temperature was raised to 600°C at 2°C / min, and then to 900°C at 5°C / min, then kept at 900°C for more than 3 hours, and finally cooled down to room t...

Embodiment 2

[0039] Embodiment 2 prepares a kind of ribbon-shaped graphite with high specific surface area according to the following steps:

[0040] (1) Petroleum pitch / silicone gel was prepared according to step (1) in Example 1;

[0041] (2) Dry the gel obtained in step (1) at 100 °C, and then pre-oxidize it in an air atmosphere at 280 °C for 6 hours to obtain a pitch / silica composite; put the pitch / silica composite into In the carbonization furnace, under the protection of nitrogen atmosphere, the temperature was raised to 600°C at 4°C / min, and then to 900°C at 8°C / min, then kept at 900°C for 1 hour, and finally cooled down to room temperature naturally to obtain a black carbon / silicon dioxide composite thing;

[0042] (3) Add excess hydrofluoric acid to the carbon / silica composite obtained in step (2) and stir for 10 hours to fully wash away the silica template, then wash with distilled water until neutral, dry to obtain mesopores carbon material;

[0043] (4) Put the mesoporous ca...

Embodiment 3

[0046] Prepare a kind of ribbon-shaped graphite with high specific surface area according to the following steps:

[0047] (1) Petroleum pitch / silicone gel was prepared according to step (1) in Example 1;

[0048] (2) Dry the gel obtained in step (1) at 100 °C, and then pre-oxidize it in an air atmosphere at 300 °C for 8 hours to obtain a pitch / silica composite; put the pitch / silica composite into In the carbonization furnace, under the protection of nitrogen atmosphere, the temperature was raised to 600°C at 6°C / min, and then to 800°C at 8°C / min, then kept at 800°C for 3 hours, and finally cooled down to room temperature naturally to obtain a black carbon / silicon dioxide composite thing;

[0049] (3) Add excess hydrofluoric acid to the carbon / silica composite obtained in step (2) and stir for 18 hours to fully wash away the silica template, then wash with distilled water until neutral, dry to obtain mesoporous carbon material;

[0050] (4) Put the mesoporous carbon materia...

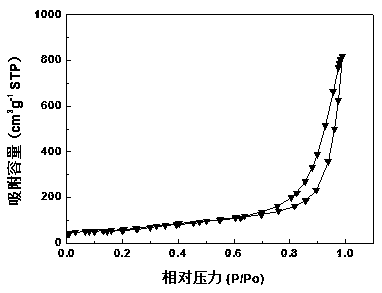

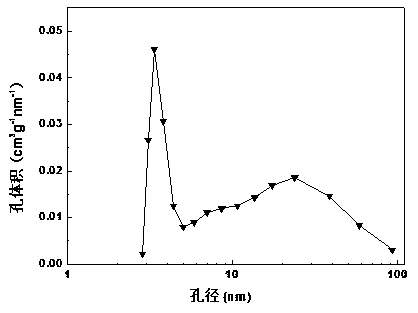

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com