Method for preparing terephthalic acid through degradation of waste PET

A terephthalic acid and waste technology, applied in the preparation of carboxylate/lactone, organic chemistry, etc., can solve the problems of many by-products and low yield of terephthalic acid, achieve high conversion efficiency and increase the reaction interface , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

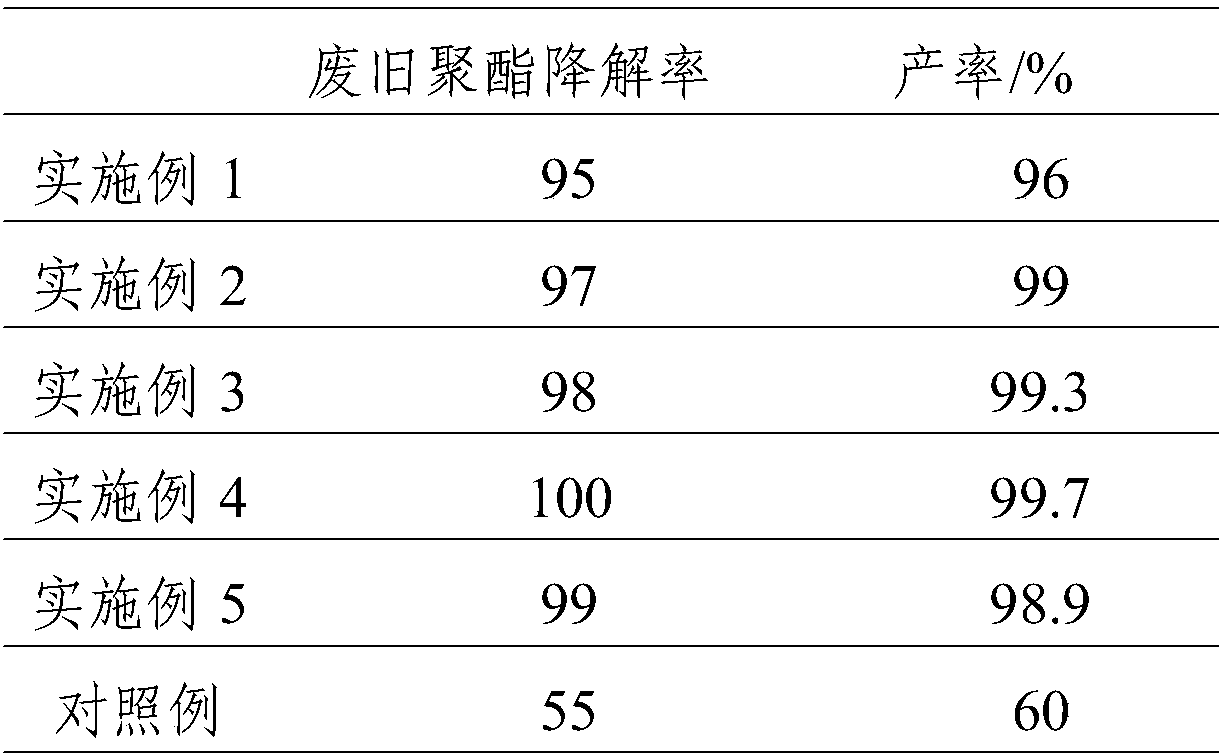

Embodiment 1

[0038] A method for preparing terephthalic acid by waste PET degradation, is characterized in that, the preparation method comprises the following steps:

[0039] (1) Add 20 parts of waste PET fragments into the hydrothermal kettle, add a depolymerization solvent with a liquid-solid mass ratio of 1:1, add a depolymerization catalyst according to 0.5% of the mass of waste PET fragments, and then add 2 zeolites;

[0040] (2) Put the hydrothermal kettle in a heater at 180°C. After reacting for 1 hour, take out the hydrothermal kettle and cool it to room temperature. As for the microwave oven, install an air condenser and a spherical condenser in sequence, and set the reaction time as 20min, adjust the microwave power to 450W after starting, and adjust the power to 150W after reflowing for 2min;

[0041] (3) Add 5 parts of boiling water to the product obtained in step (2), stir to dissolve it fully, filter it in the Buchner funnel, put the filtrate in the heating pot, add 2 zeolit...

Embodiment 2

[0044]A method for preparing terephthalic acid by waste PET degradation, is characterized in that, the preparation method comprises the following steps:

[0045] (1) Add 30 parts of waste PET fragments into the hydrothermal kettle, add a depolymerization solvent with a liquid-solid mass ratio of 3:1, add a depolymerization catalyst according to 2.0% of the mass of waste PET fragments, and then add 2 zeolites;

[0046] (2) Put the hydrothermal kettle in a heater at 240°C, and after reacting for 3 hours, take out the hydrothermal kettle and cool it to room temperature. As for the microwave oven, install the air condenser and the spherical condenser in sequence, and set the reaction time as 20min, adjust the microwave power to 450W after starting, and adjust the power to 150W after reflowing for 2min;

[0047] (3) Add 10 parts of boiling water to the product obtained in step (2), stir to make it fully dissolve, filter it in the Buchner funnel, put the filtrate in a heating pot, a...

Embodiment 3

[0050] A method for preparing terephthalic acid by waste PET degradation, is characterized in that, the preparation method comprises the following steps:

[0051] (1) Add 25 parts of waste PET fragments to the hydrothermal kettle, add a depolymerization solvent with a liquid-solid mass ratio of 2:1, add a depolymerization catalyst according to 1.0% of the mass of waste PET fragments, and then add 2 zeolites;

[0052] (2) Put the hydrothermal kettle in a heater at 200° C. After reacting for 2 hours, take out the hydrothermal kettle and cool it to room temperature. As for the microwave oven, install an air condenser and a spherical condenser in sequence, and set the reaction time as 20min, adjust the microwave power to 450W after starting, and adjust the power to 150W after reflowing for 2min;

[0053] (3) Add 6 parts of boiling water to the product obtained in step (2), stir to make it fully dissolve, filter it in the Buchner funnel, put the filtrate in a heating pot, add 2 zeo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com