Magnetic chelating resin, preparation method and application thereof in purification of compound polluted water

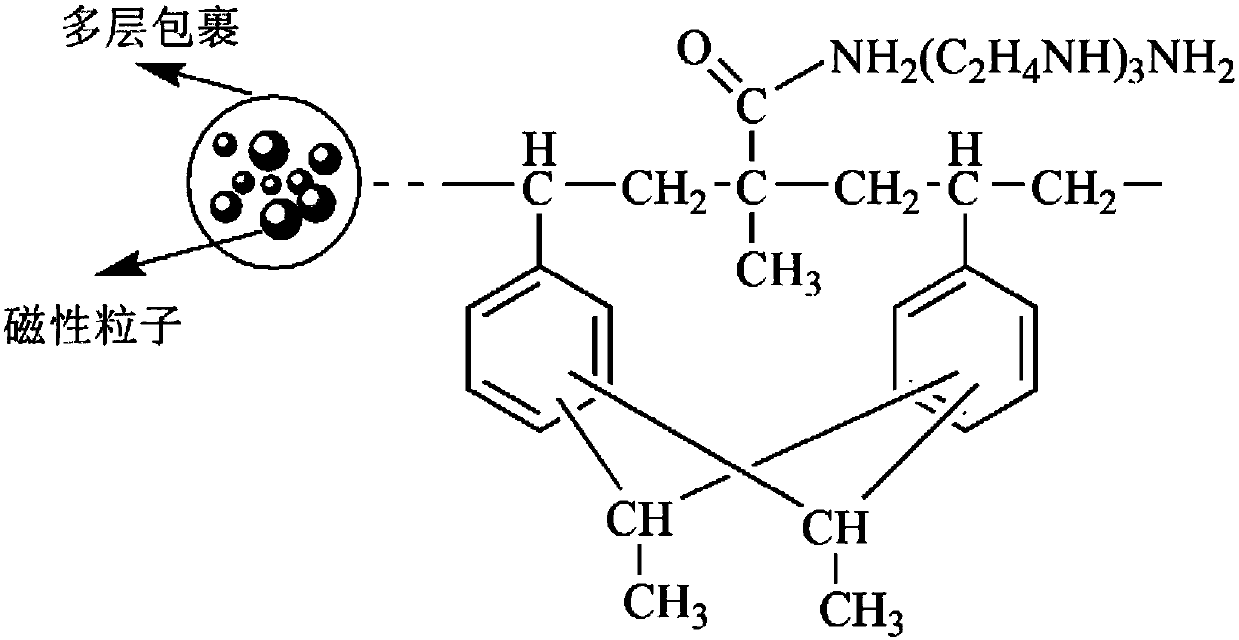

A chelating resin and magnetic technology, applied in the field of magnetic chelating resin and its preparation, can solve the problems such as the difficult fusion of magnetic nanoparticles and reaction monomers effectively, and the acid resistance of the resin is not strong, so as to solve the problem of poor removal effect and improve Yield, Ease of Magnetic Separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

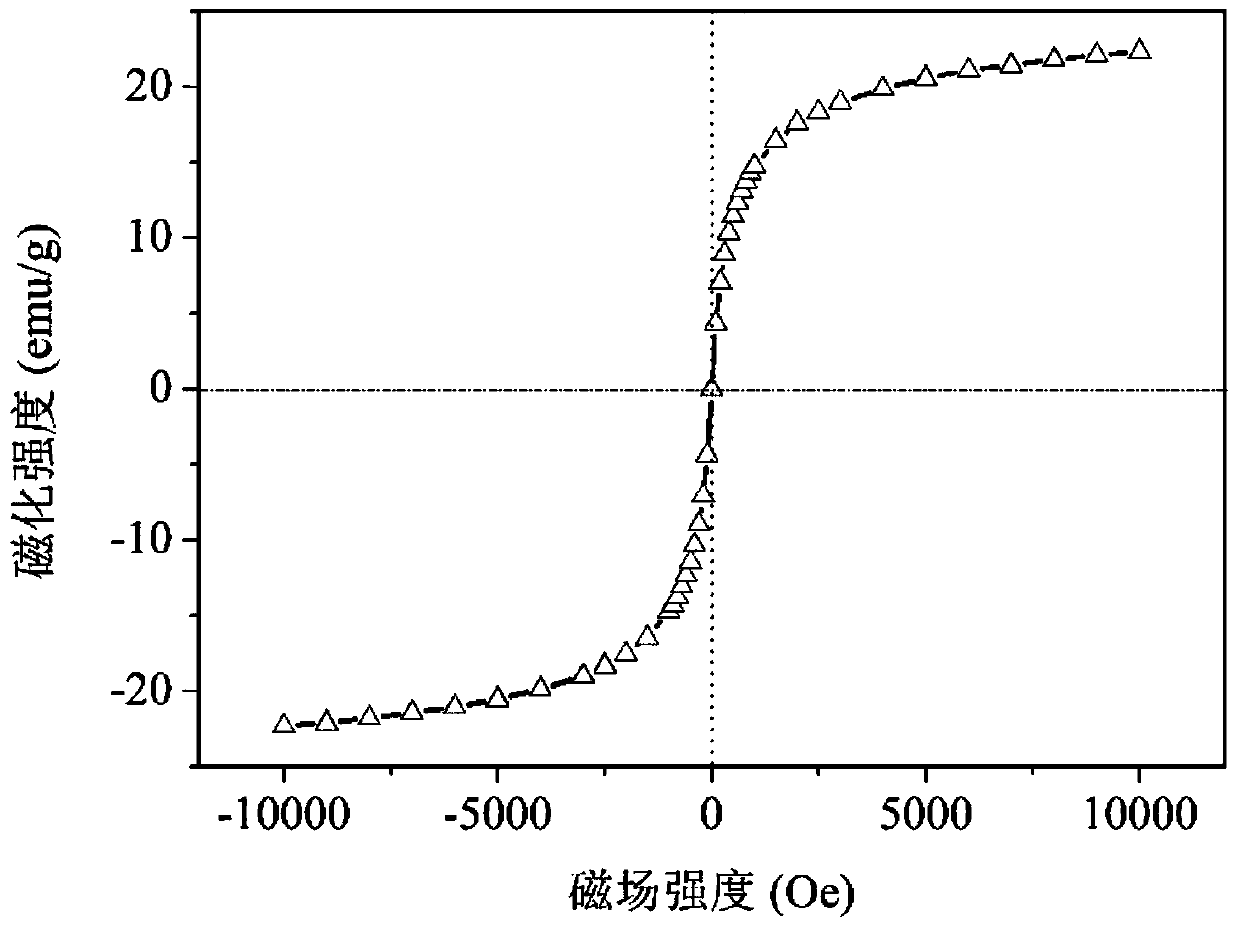

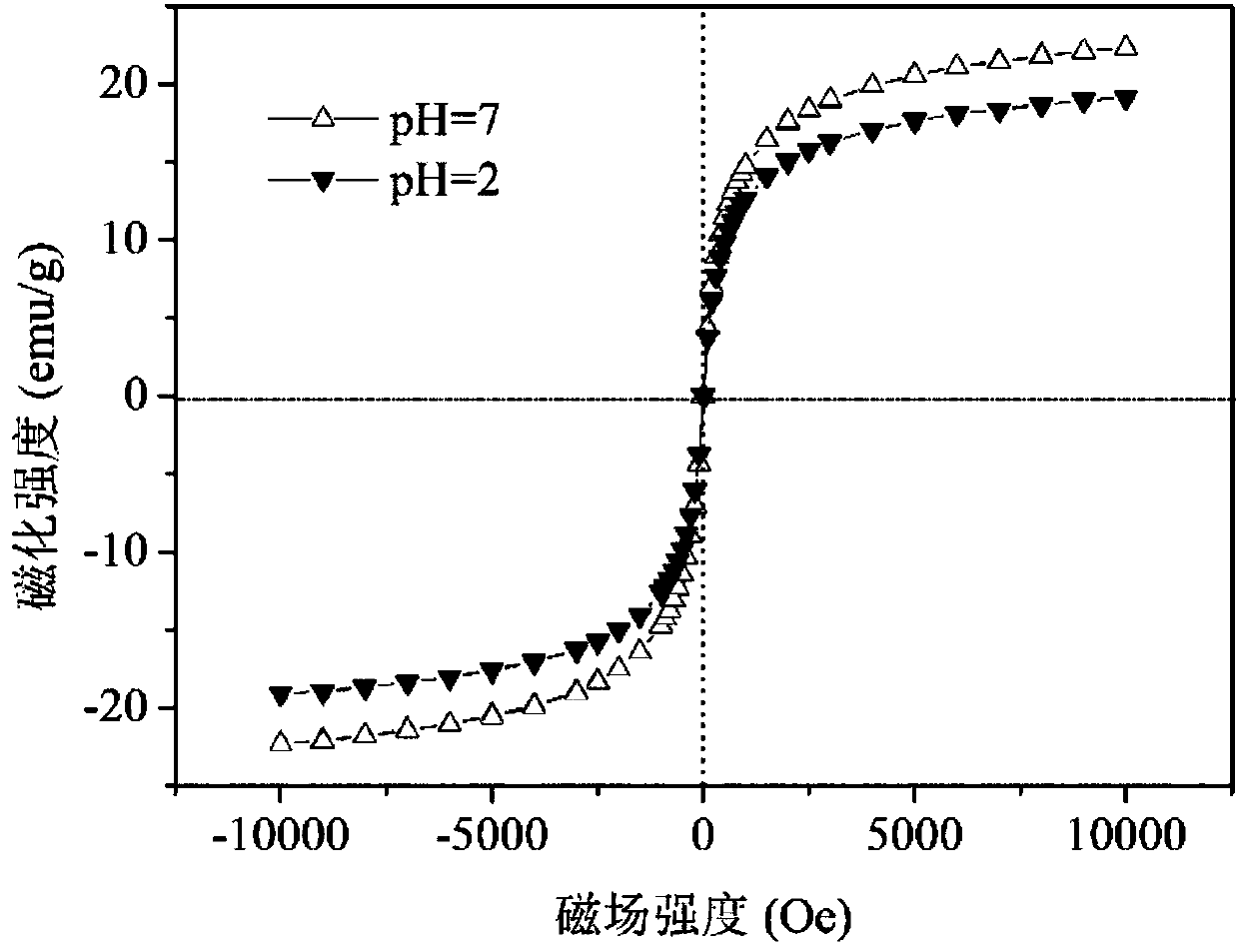

[0034] Dissolve 0.1mol of ferric chloride hexahydrate and 0.04mol of ferrous chloride tetrahydrate in 500mL of deionized water, raise the temperature to 75°C for 30min under the protection of nitrogen, and prepare magnetic nanoparticles, cool and wash;

[0035] Add 10 g of the prepared magnetic particles to 200 mL of ammonia water with a concentration of 0.16%, stir and mix evenly, add 10 g of oleic acid for modification, raise the temperature to 75 ° C for 30 min, rinse with methanol, and then mix it with 100 g of acetone. Add 20g vinyltriethoxysilane dissolved in 100g acetone to 200mL ammonia water with a concentration of 25%. After reacting at 30°C for 4 hours, add 20g methacryloxypropyltrimethylsilane dissolved in 100g acetone Oxysilane was modified again at 30°C for 4 hours, rinsed with methanol after cooling;

[0036]After mixing 14.4g of modified magnetic nanoparticles with 20g of divinylbenzene, 12g of methyl acrylate, 16g of toluene, and 0.24g of benzoyl peroxide, the...

Embodiment 2

[0043] Dissolve 0.03mol of ferric chloride hexahydrate and 0.018mol of ferrous chloride tetrahydrate in 500mL of deionized water, heat up to 85°C under the protection of nitrogen and react for 60min to prepare magnetic nanoparticles, cool and wash;

[0044] Add 3 g of the prepared magnetic particles to 200 mL of ammonia water with a concentration of 0.18%, stir and mix evenly, add 15 g of oleic acid for modification, raise the temperature to 85 ° C for 60 min, rinse with methanol, and then mix it with 100 g of acetone Add 30g vinyltriethoxysilane dissolved in 300g acetone to 200mL ammonia water with a concentration of 28%. After reacting at 50°C for 8 hours, add 30g methacryloxypropyltrimethylsilane dissolved in 300g acetone Oxysilane was modified again at 50°C for 8 hours, rinsed with methanol after cooling;

[0045] After mixing 4.8g of modified magnetic nanoparticles with 6g of divinylbenzene, 10g of methyl acrylate, 32g of toluene, and 0.48g of benzoyl peroxide, the temper...

Embodiment 3

[0052] Dissolve 0.05mol ferric chloride hexahydrate and 0.025mol ferrous chloride tetrahydrate in 500mL deionized water, heat up to 80°C under the protection of nitrogen and react for 40min to prepare magnetic nanoparticles, cool and wash;

[0053] Add 5 g of the prepared magnetic particles to 200 mL of ammonia water with a concentration of 0.17%, stir and mix evenly, add 10 g of oleic acid for modification, raise the temperature to 80 ° C for 40 min, rinse with methanol, and then mix it with 100 g of acetone Add 20g vinyltriethoxysilane dissolved in 150g acetone to 200mL ammonia water with a concentration of 25%. After reacting at 40°C for 6h, add 20g methacryloxypropyltrimethylsilane dissolved in 150g acetone Oxysilane was modified again at 40°C for 6 hours, rinsed with methanol after cooling;

[0054] After mixing 6g of modified magnetic nanoparticles with 10g of divinylbenzene, 10g of methyl acrylate, 20g of toluene, and 0.4g of benzoyl peroxide, the temperature was raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com