A kind of water-soluble lignin piperidinamine light stabilizer and its preparation method and application

A technology of plain piperidinamine light and plain piperidinamine, which is applied in the field of lignin materials, can solve the problems that the anti-ultraviolet performance is difficult to achieve chemically synthesized light stabilizers, the content of functional groups is small, the molecular agglomeration is serious, and the like, and the light resistance is increased. The effect of decomposing groups, large molecular weight and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

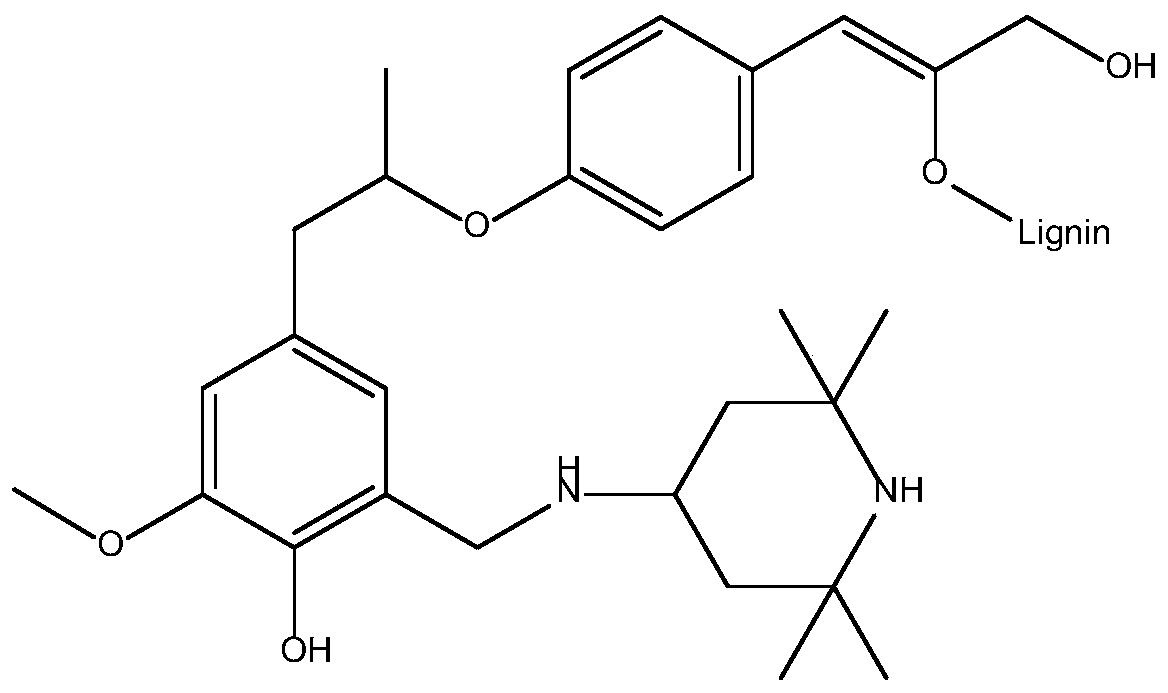

[0031] Dissolve 100g of alkali lignin in an alkaline aqueous solution to make a 20% solid solution, adjust the pH of the solution to 10; raise the temperature to 80°C, add 40g of piperidine, stir and mix evenly; then add 25g of formaldehyde dropwise to the above mixture In the solution, after 30 minutes of dropwise addition, the temperature was raised at 90° C. for 2 hours to obtain the lignin-based piperidine derivative. Structural diagram see figure 1 .

Embodiment 2

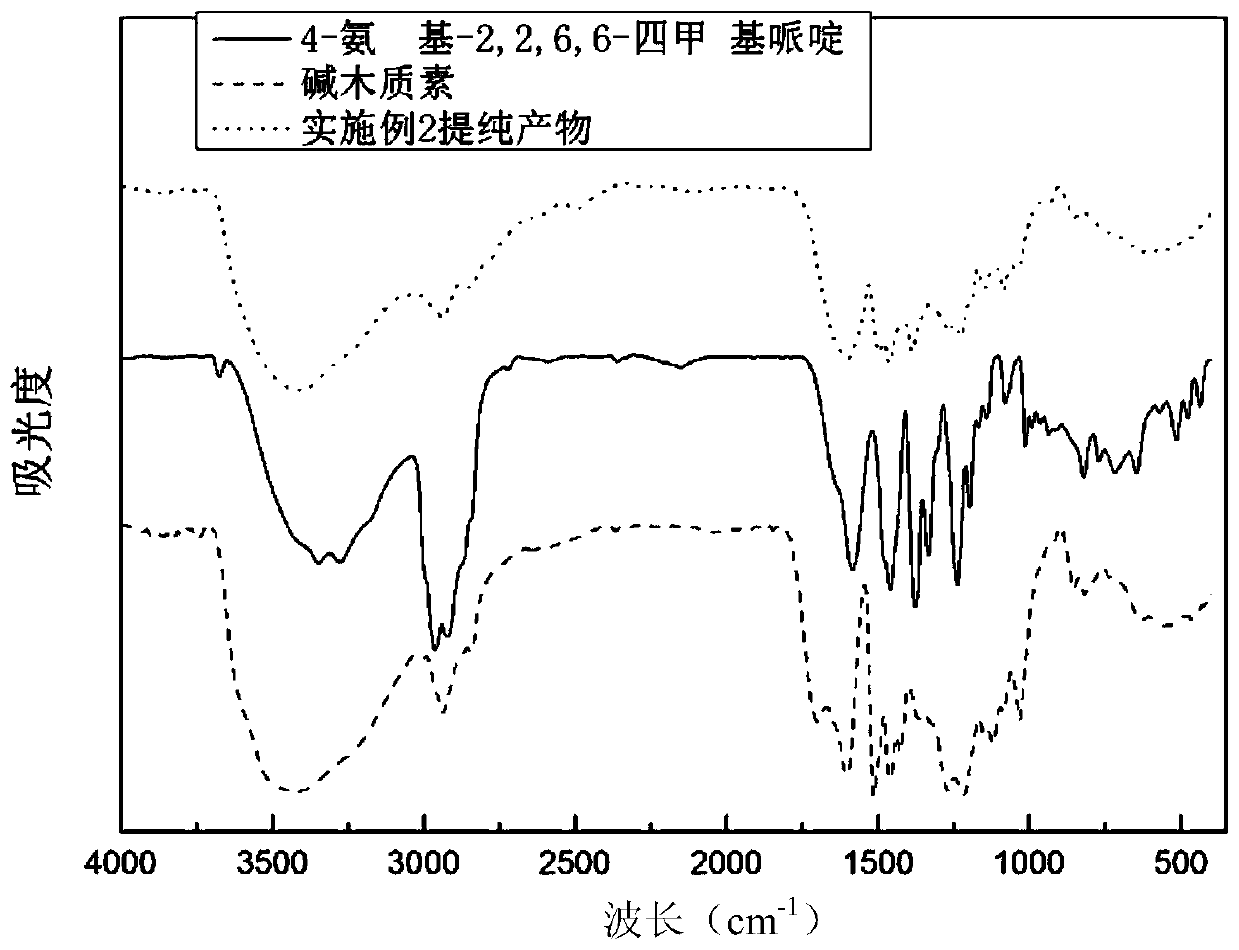

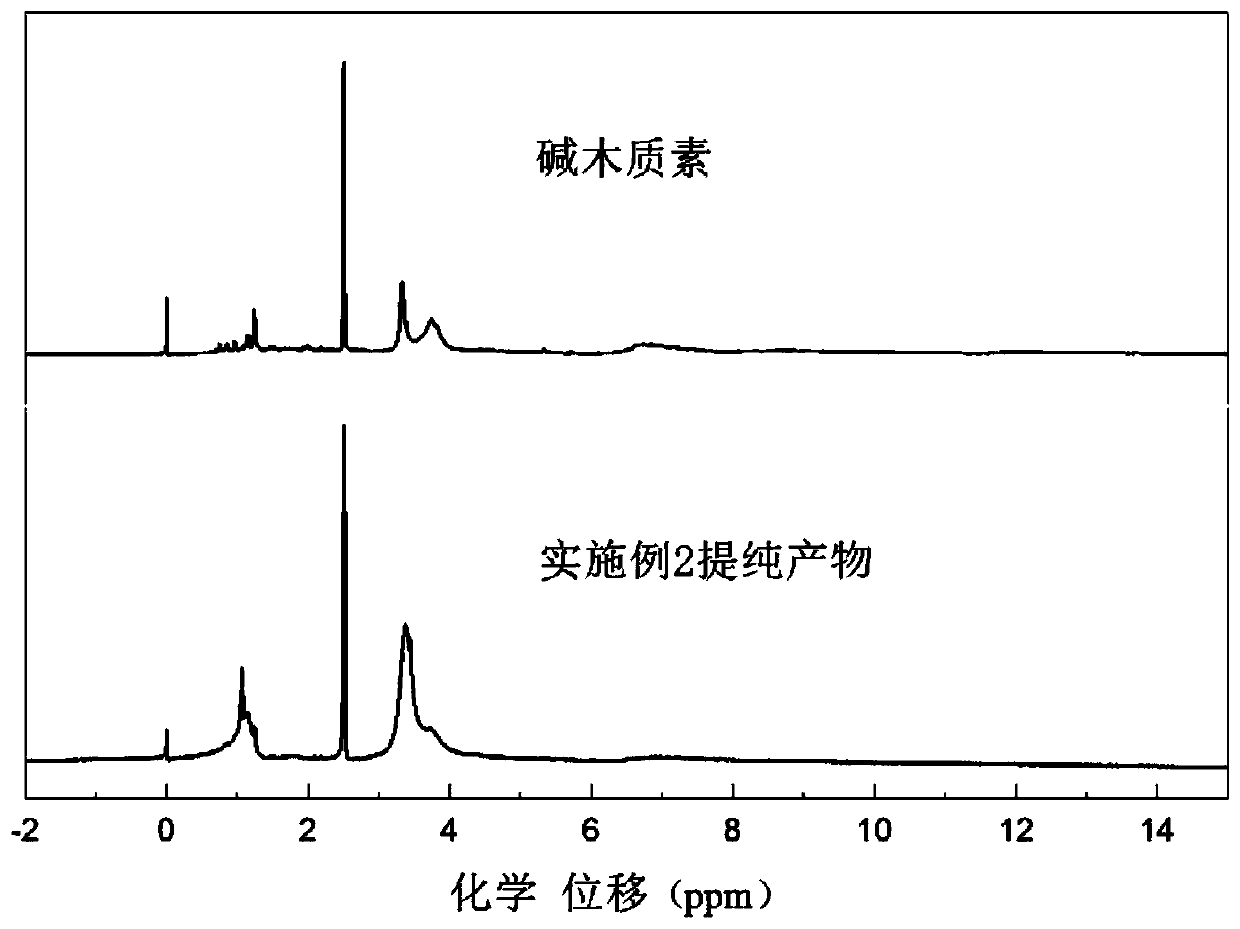

[0033] Dissolve 100g of alkali lignin in an alkaline aqueous solution to prepare a 30% solid solution, adjust the pH of the solution to 11; raise the temperature to 85°C, add 50g of 4-amino-2,2,6,6-tetramethylpiperene Pyridine, stirred and mixed evenly; then 30g of formaldehyde was added dropwise to the above mixed solution, after 60min of dropwise addition, reacted at 85°C for 3h to obtain the lignin-based piperidinamine derivative.

Embodiment 3

[0035] Dissolve 100g of alkali lignin in an alkaline aqueous solution to prepare a 40% solid solution, adjust the pH of the solution to 11; raise the temperature to 90°C, add 32g of 1-(3-methoxypropyl)-4-piperidine Amine, stirred and mixed evenly; then 10g of propionaldehyde was added dropwise to the above mixed solution, after 60min of dropwise addition, reacted at 90°C for 1h to obtain the lignin-based piperidine amine derivative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com