Fuel efficiency improvement method

A technology of fuel efficiency and fuel oil, which is applied in the direction of fuel, petroleum industry, and liquid carbon-containing fuels. It can solve problems such as insufficient power, low calorific value, and cumbersome refitting of internal combustion engines, so as to save maintenance costs and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

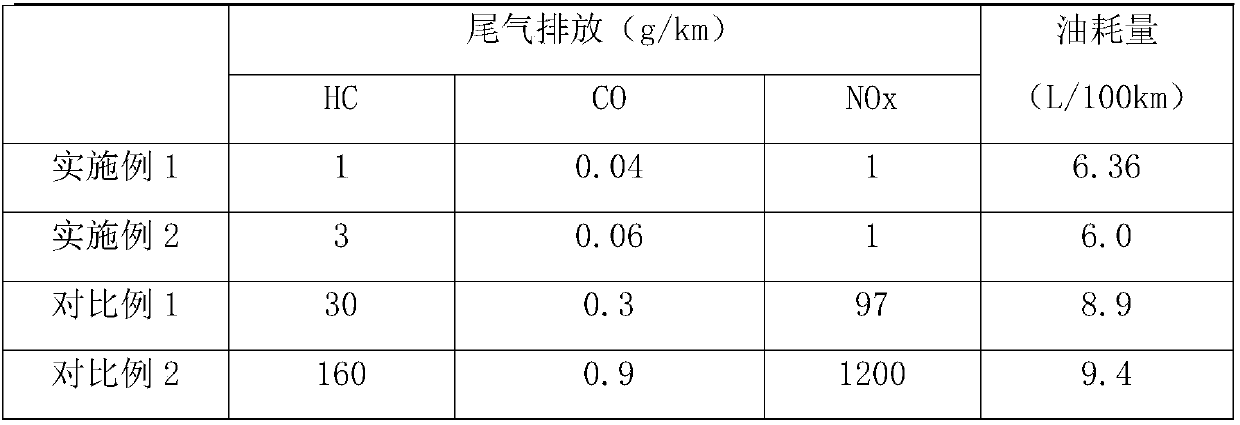

Embodiment 1

[0014] One way to improve fuel efficiency:

[0015] (1) Preparation of fuel additive: the fuel additive is made from the following raw materials in weight ratio:

[0016] 90 parts of SF grade engine oil for gasoline engine, 0.5 part of BHT, and 0.5 part of lanthanum; the preparation method is as follows: heat all raw materials to 85°C under anaerobic conditions, keep them warm for 24 hours, then cool to room temperature, concentrate, separate, and remove more than The liquid particle of 5 microns promptly gets the fuel additive of the present invention;

[0017] (2) Atomization of fuel additive: inject and atomize the fuel additive, control the atomized particle size to be less than 5 microns, and the injection amount is 0.08% of the fuel amount. The atomized steam and air are sent into the combustion chamber and mixed with fuel for combustion.

Embodiment 2

[0019] (1) Preparation of fuel additive: the fuel additive is made from the following raw materials in weight ratio:

[0020] 90 parts of SF grade engine oil for gasoline engine, 0.5 part of BHT, and 0.5 part of lanthanum; the preparation method is as follows: heat all raw materials to 85°C under anaerobic conditions, keep them warm for 24 hours, then cool to room temperature, concentrate, separate, and remove more than The liquid particle of 5 microns promptly gets the fuel additive of the present invention;

[0021] (2) Atomization of fuel additives: evaporate and atomize fuel additives, control the evaporation particle size to be less than 5 microns, inject 0.03% of the fuel, and send the atomized steam and air into the combustion chamber for mixed combustion with the fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com