Apodized grating double-exposure making system and method based on dynamic optical shield plate

A secondary exposure and optical shading technology, applied in optics, optical components, optical waveguide and light guide, etc., can solve problems such as poor repeatability, inability to strictly control the shape of the apodization function, and high coherence requirements for ultraviolet light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

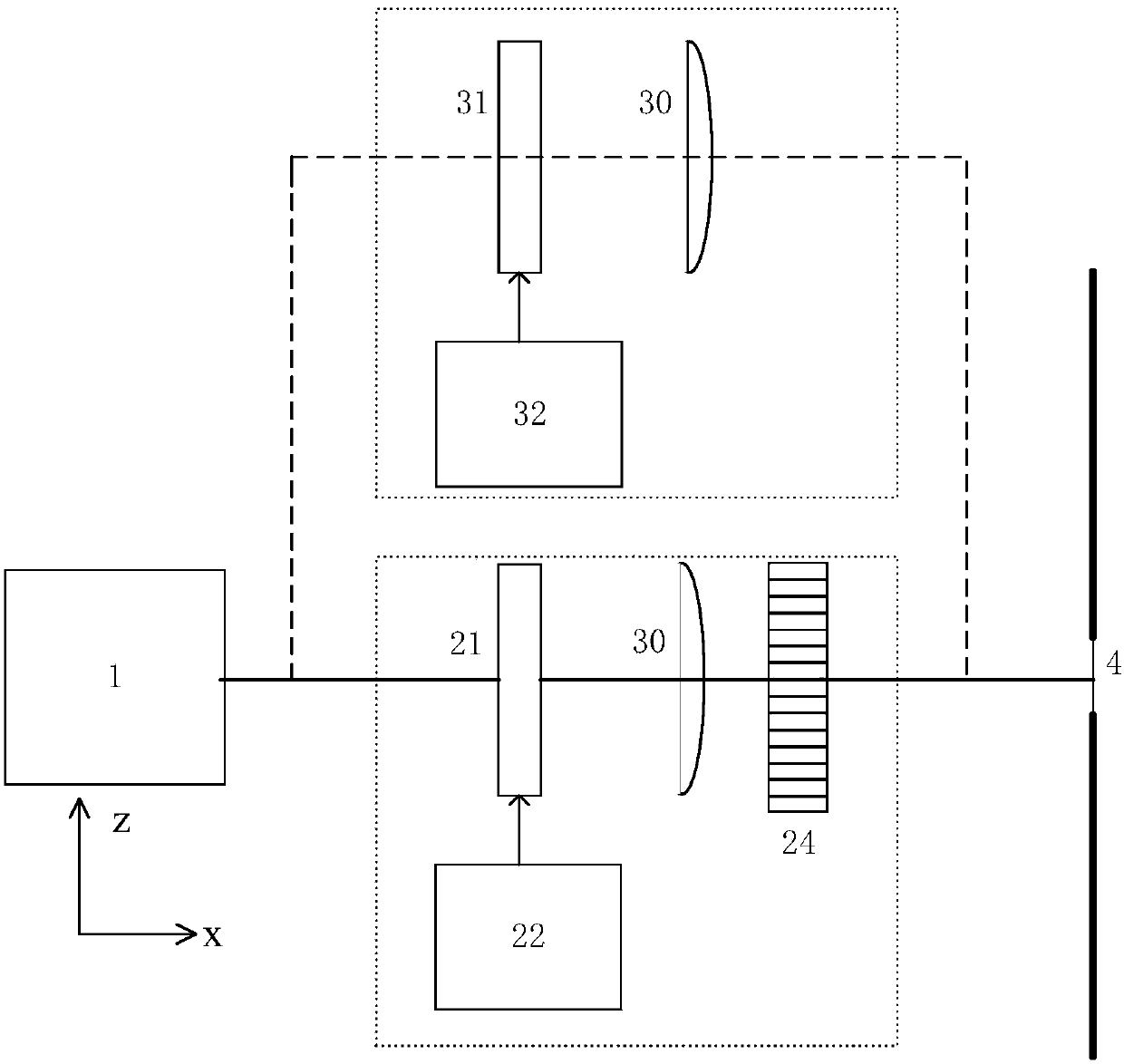

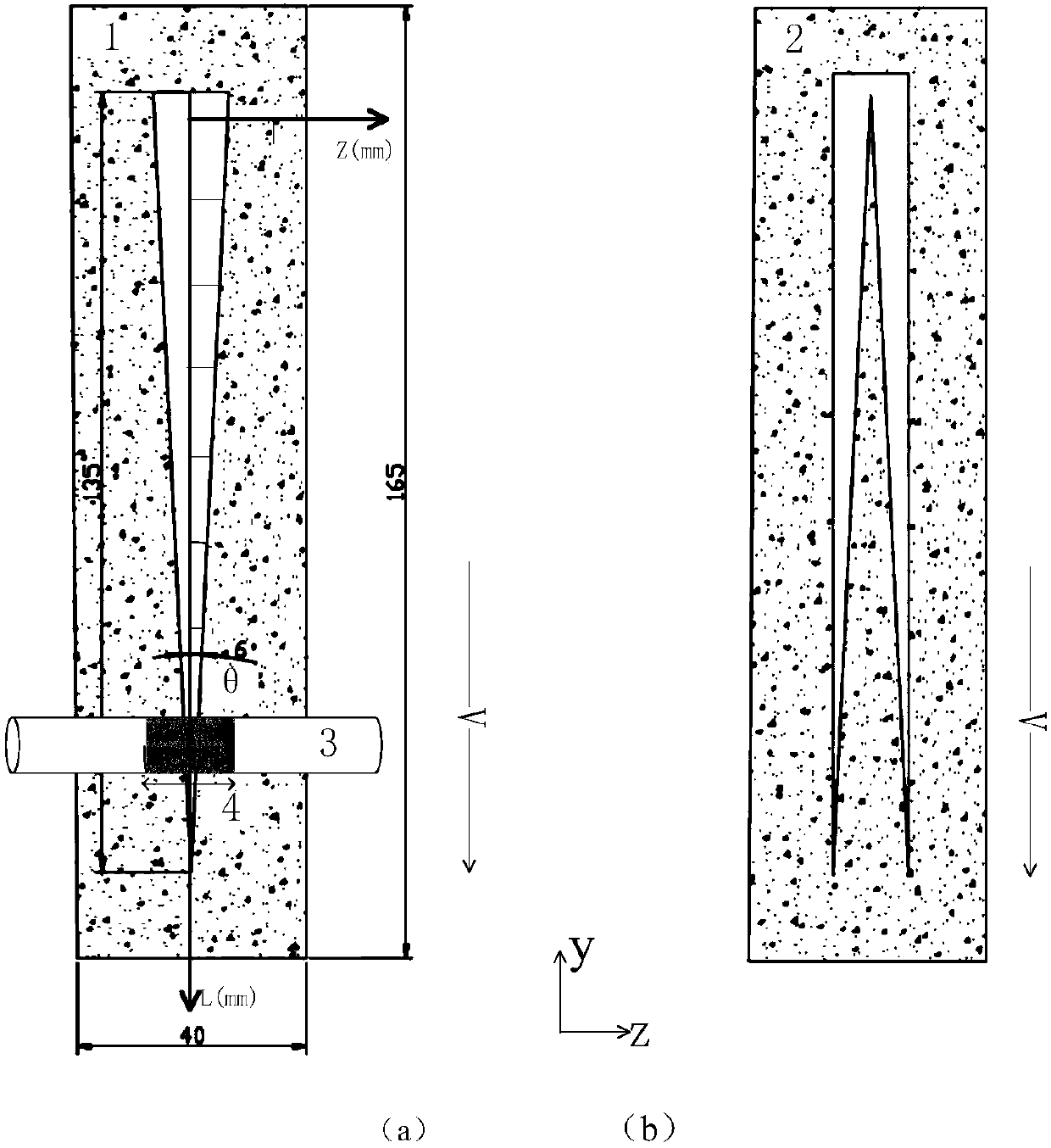

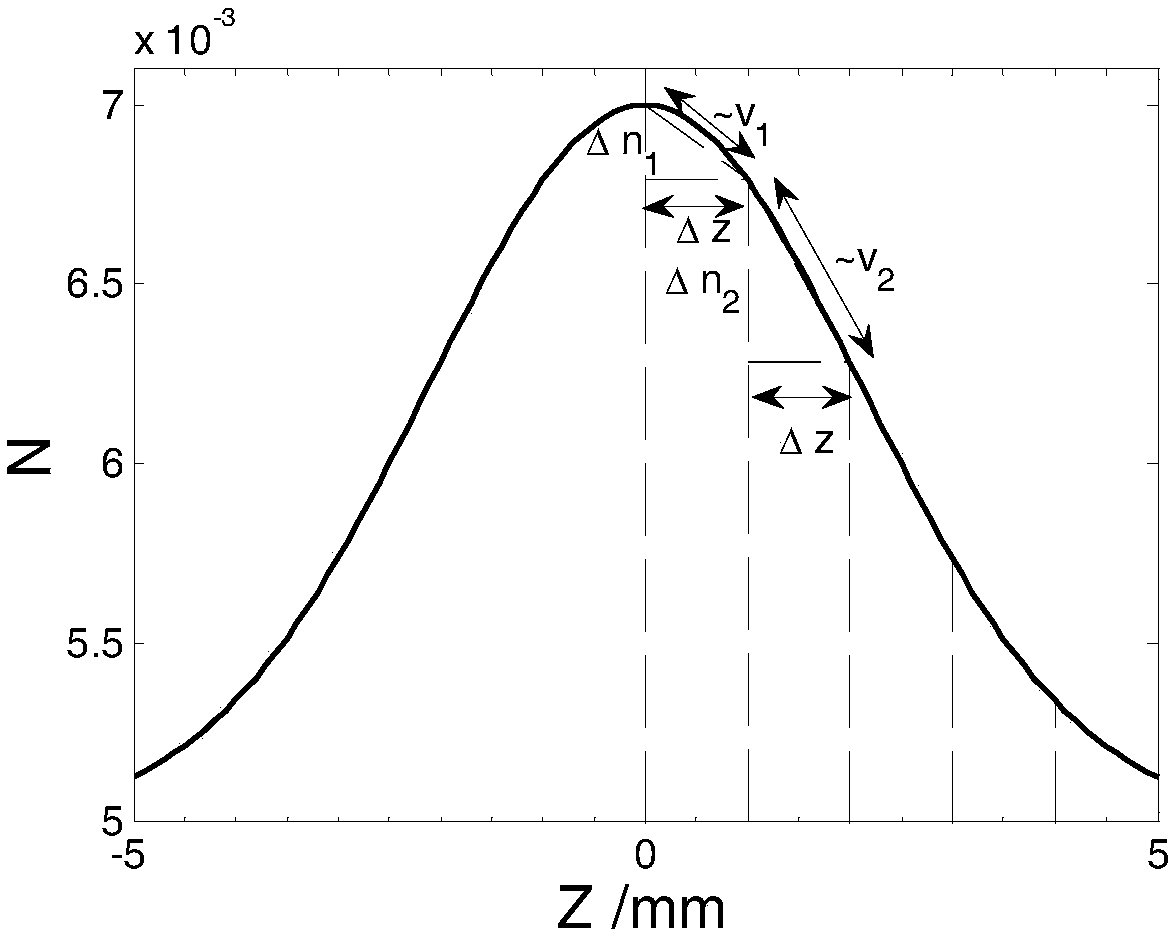

[0087] This embodiment adopts a distributed compensation method, such as Figure 4 As shown, between the ultraviolet excimer laser 1 and the optical path of the hydrogen-carrying fiber to be prepared, an optical shielding plate 21 for primary exposure, optical compensation plate for secondary exposure 31, plano-convex cylindrical mirror 30, uniform Phase mask 24 and uniform phase mask controller 52; the ultraviolet excimer laser emits ultraviolet light along the x-axis, which is shaped after a single exposure optical shielding plate, and the single-exposure optical shielding plate moves along the y-axis from the place where the light flux is minimum to At the place where the luminous flux is maximum, the controller of the one-time exposure optical shielding plate controls the movement displacement and speed of the one-time exposure optical shielding plate according to the motion function, so as to control the exposure length and exposure time of ultraviolet light in different are...

Embodiment 2

[0095] This embodiment adopts the simultaneous compensation method, such as Figure 5 As shown, the ultraviolet excimer laser emits ultraviolet light along the x-axis, which is divided into two beams by the beam splitter 7, and is placed one time along the x-axis between the first ultraviolet light and the optical path of the hydrogen-carrying fiber to be prepared The exposure optical shielding plate 21, the first plano-convex cylindrical mirror 23 and the uniform phase mask 24 are placed between the second ultraviolet light and the optical path of the hydrogen-carrying fiber to be prepared, and the second exposure optical compensation is sequentially placed along the x axis The plate 31 and the second plano-convex cylindrical lens 33; the first ultraviolet light is shaped by the one-time exposure optical shielding plate, and the one-time exposure optical shielding plate controller controls the movement displacement and speed of the one-time exposure optical shielding plate accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com