Catalytic ozonation catalyst as well as preparation method and application thereof

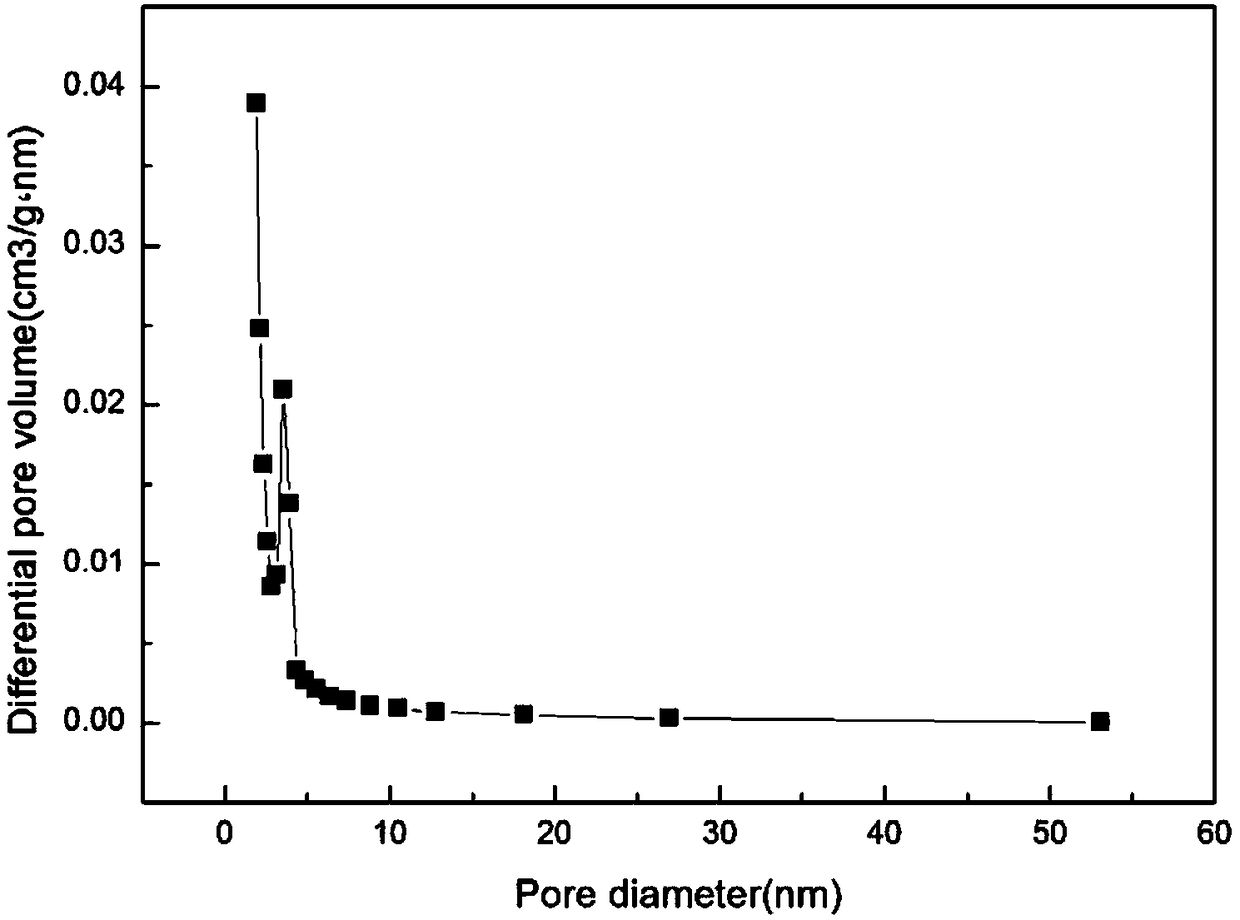

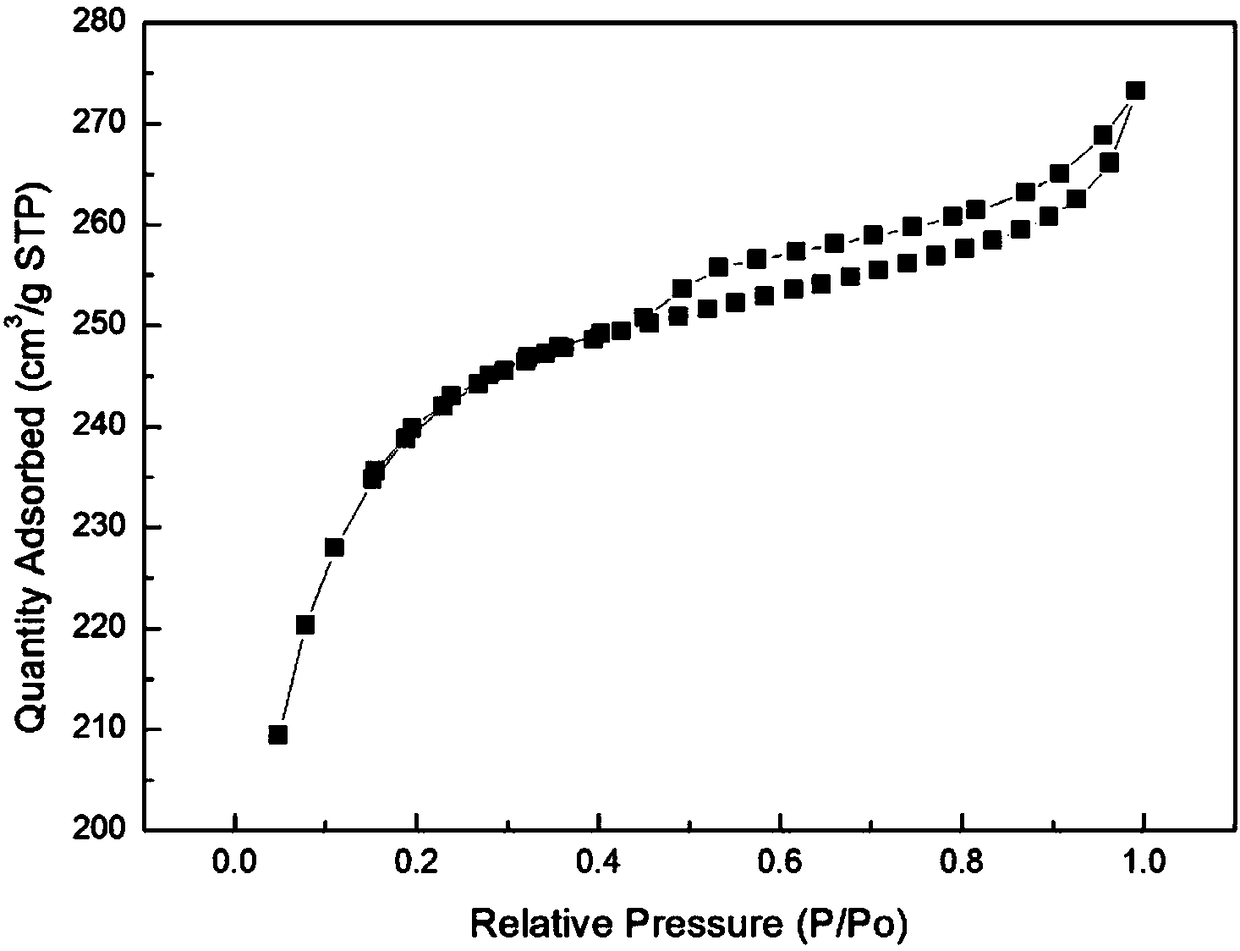

An ozone catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as low catalytic efficiency, reduce diffusion resistance, large pore size and pore volume, The effect of improving the COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

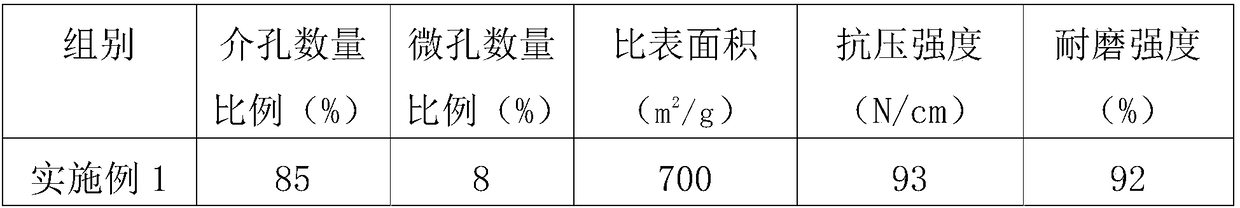

Embodiment 1

[0047] The preparation method of the ozone catalytic oxidation catalyst in this embodiment includes the following steps:

[0048] A) Use a pulverizer to pulverize 100g of raw coal to a particle size of no more than 75μm, then add 15g of active ingredients and mix well, and then add 5g of coal tar for kneading, and then squeeze it into molding equipment to obtain molding materials;

[0049] B) Place the molding material in a carbonization furnace and carbonize under anaerobic conditions. The carbonization temperature is 400°C and the carbonization time is 60min. After the carbonization is completed, the material will be discharged from the outlet for cooling; then the carbonized material after carbonization is activated In the furnace, steam is used as the activator to activate at 1000°C for 20 hours, and the mass ratio of the amount of steam to the raw coal is 20:1, and finally the ozone catalytic oxidation catalyst is obtained;

[0050] Wherein, the active component is KNO 3 , Fe(NO...

Embodiment 2

[0052] The preparation method of the ozone catalytic oxidation catalyst in this embodiment includes the following steps:

[0053] A) Use a pulverizer to pulverize 500g of raw coal to a particle size of not more than 75μm, then add 5g of active ingredients and mix well, then add 100g of coal tar for kneading, and then squeeze it into molding equipment to obtain molding material;

[0054] B) Place the molding material in a carbonization furnace and carbonize under anaerobic conditions. The carbonization temperature is 600°C and the carbonization time is 10 minutes. After the carbonization is completed, the material is discharged from the outlet to cool; then the carbonized material after carbonization is activated In the furnace, steam is used as the activator to activate at 700°C for 60 hours, and the mass ratio of the amount of steam to the raw coal is 15:1, and finally the ozone catalytic oxidation catalyst is obtained;

[0055] Wherein, the active component is KNO 3 , Fe(NO 3 ) 3 A...

Embodiment 3

[0057] The preparation method of the ozone catalytic oxidation catalyst in this embodiment includes the following steps:

[0058] A) Use a pulverizer to pulverize 100g of raw coal to a particle size of not more than 75μm, then add 5g of active ingredients and mix well, then add 10g of coal tar for kneading, and then squeeze it into molding equipment to obtain molding materials;

[0059] B) Place the molding material in a carbonization furnace and carbonize under anaerobic conditions. The carbonization temperature is 500°C and the carbonization time is 30min. After the carbonization is completed, the material is discharged from the outlet for cooling; then the carbonized material after carbonization is activated In the furnace, steam is used as the activator to activate at 900°C for 40 hours, and the mass ratio of the amount of steam to the raw coal is 20:1, and finally the ozone catalytic oxidation catalyst is obtained;

[0060] Wherein, the active component is Na 2 CO 3 , Cu(NO 3 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com