Coupling-type multiplier

A drag reduction and sucker rod technology, applied in drilling equipment, earthmoving, drill pipe, etc., can solve the problems of downhole tubing and sucker rod loss, breakage, oil production loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

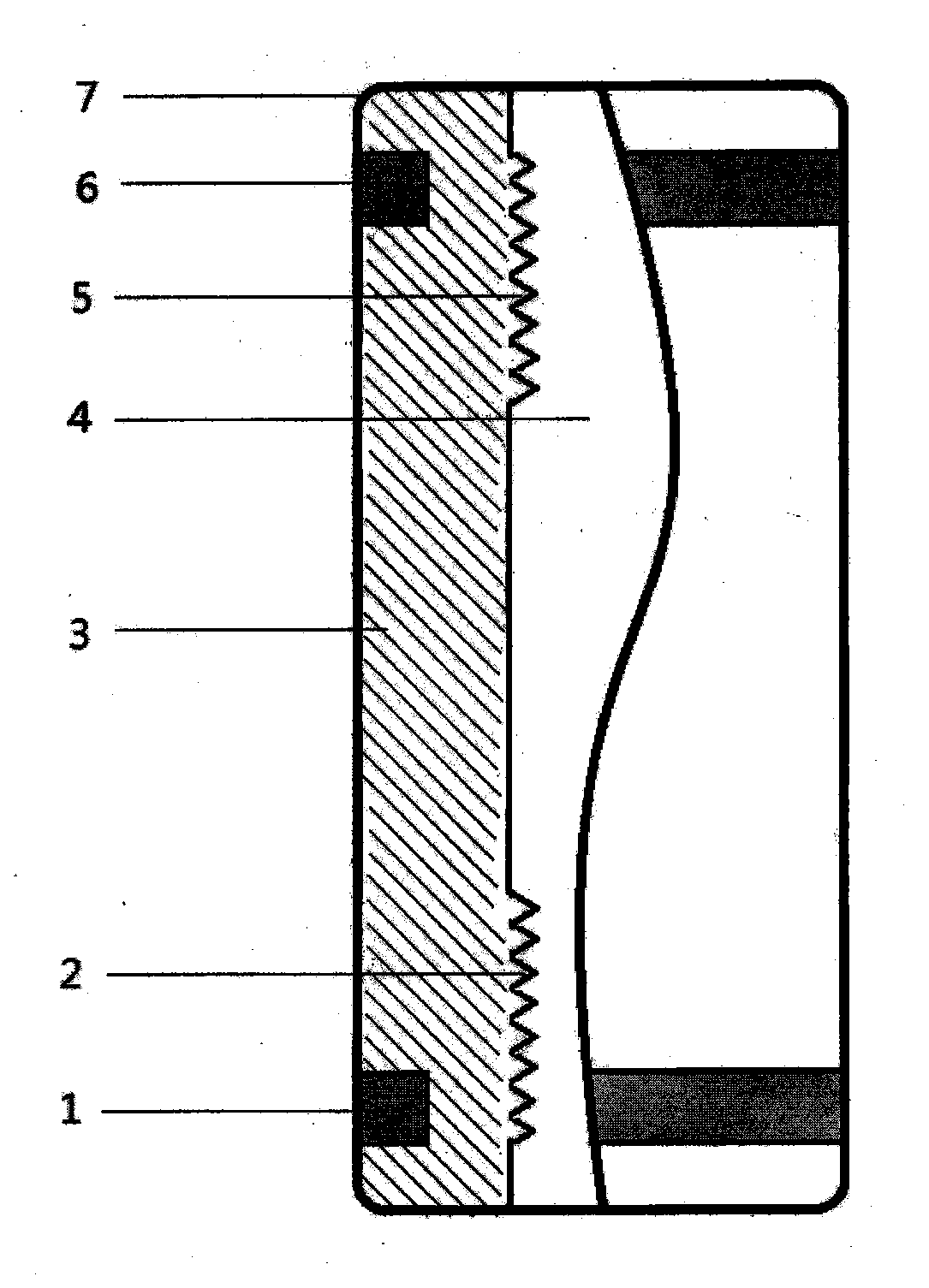

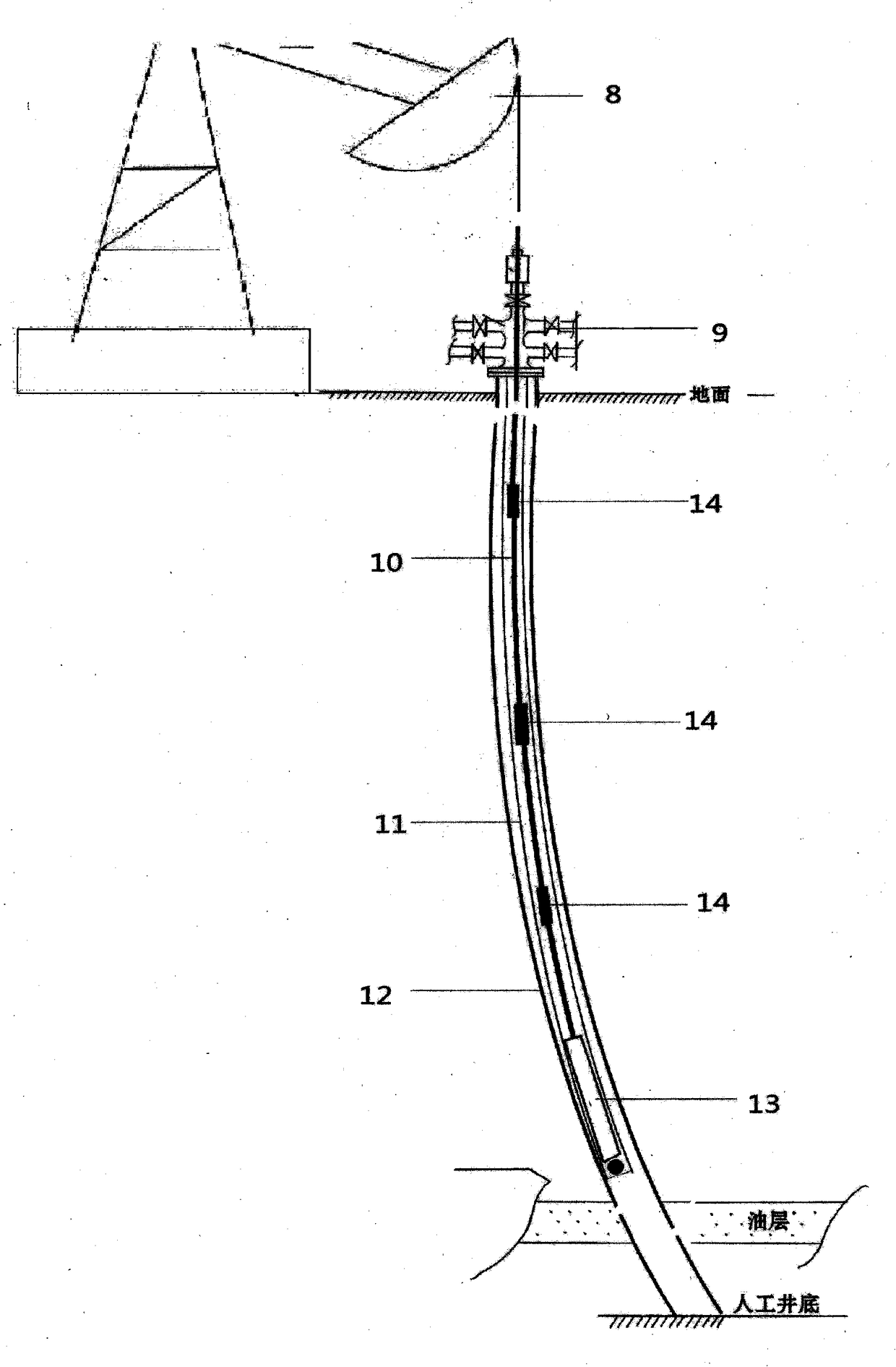

[0011] Such as figure 1 The present invention of the structure shown is called: collar type multiplier, and its installation and implementation position is figure 2 The position of the invention 14 is shown. In oil extraction, oil well production consists of figure 2 The shown facilities mainly include: pumping unit 8 , wellhead Christmas tree 9 , sucker rod 10 , oil pipe 11 , oil well pump 13 , and casing 12 . The position of the present invention 14 is just installed in the oil pipe 12, above the oil well pump 13, is connected in series on the sucker rod 10, and moves up and down with the oil sucker rod 8 in the oil pipe 11.

[0012] In the present invention, metal copper or nickel with a small friction coefficient is embedded in the two ends of the cylindrical anti-wear body 3, that is, the lower drag-reducing ring 1 and the upper drag-reducing ring 6. When rubbing against the inner wall of the oil pipe 12, the metallic copper or nickel can act as the friction The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com