Royal jelly extract for promoting synthesis of collagen and extracting method and application of royal jelly extract

A royal jelly extract and collagen synthesis technology, which is applied in medical preparations containing active ingredients, food science, pharmaceutical formulas, etc., can solve the problems of less research and utilization, low amount of royal jelly added, and difficulty in reaching the effective concentration of skin care active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

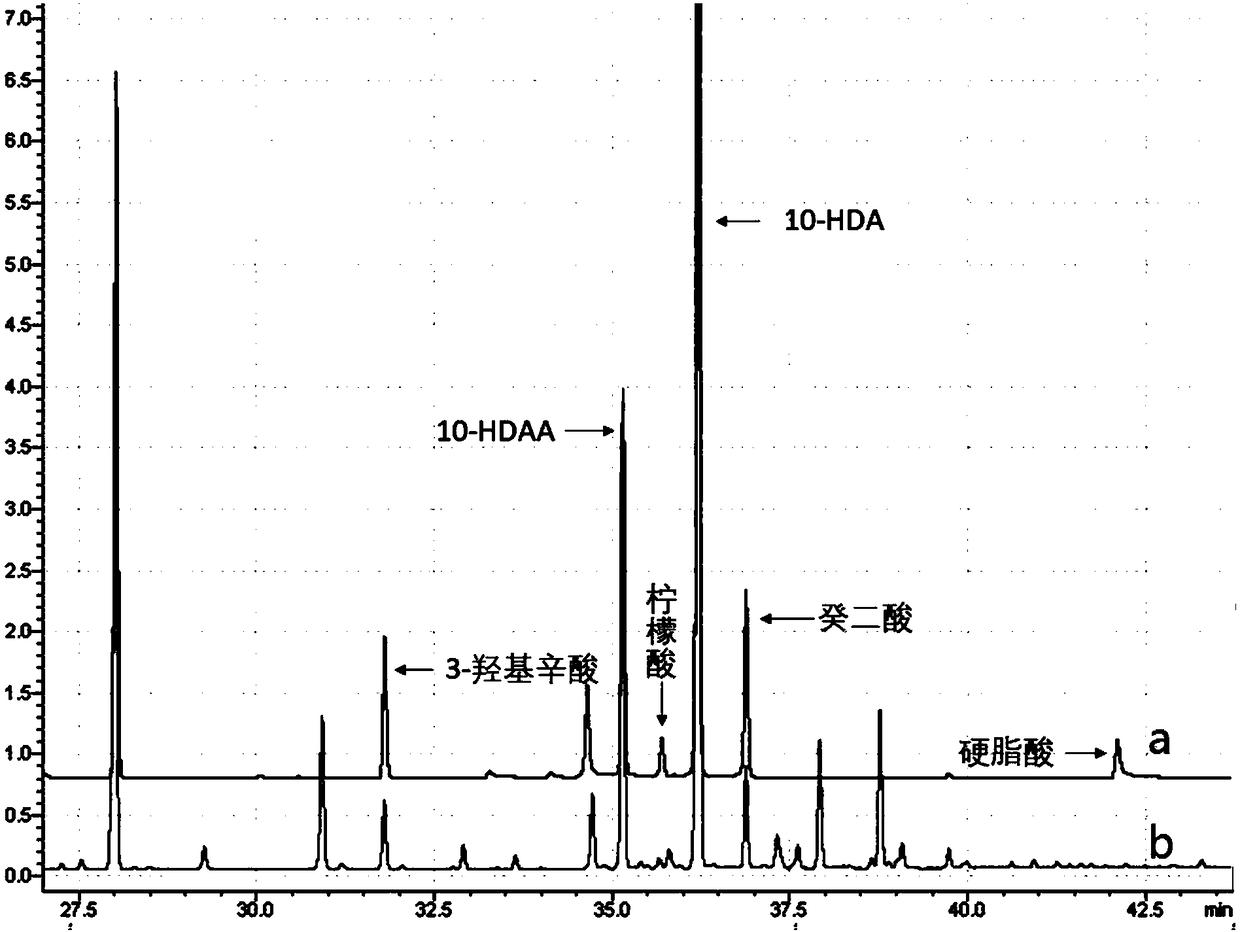

Image

Examples

Embodiment 1

[0074] Example 1: Extraction of royal jelly extract of the present invention

[0075] The implementation steps of this embodiment are as follows:

[0076] A. Extraction

[0077] According to the weight ratio of royal jelly to purified water 1:5, add the royal jelly sold by Jiangxi Wang's Bee Garden Co., Ltd. under the trade name royal jelly to purified water, mix well, and extract for 12h at a temperature of 30°C and a stirring speed of 800rpm. A centrifuge sold under the trade name of a low-speed desktop centrifuge by Shanghai Anting Scientific Instrument Factory was used for centrifugal separation for 36 minutes under the condition of a centrifugal force of 4000g, and the supernatant obtained was sold under the trade name of nylon yarn by Shanghai Yanjin Filter Mesh Factory Filter with a 400 mesh nylon yarn filter screen to collect the filter cake;

[0078] B. Dissolve

[0079] According to the weight ratio of the filter cake to the aqueous sodium hydroxide solution of 1:2, the filt...

Embodiment 2

[0082] Example 2: Extraction of royal jelly extract of the present invention

[0083] The implementation steps of this embodiment are as follows

[0084] A. Extraction

[0085] According to the weight ratio of royal jelly to purified water 1:8, add the royal jelly sold by Jiangxi Wang's Bee Garden Co., Ltd. under the trade name royal jelly to purified water, mix well, and extract for 16h at a temperature of 50℃ and a stirring speed of 1600rpm , Using a centrifuge sold by Shanghai Anting Scientific Instrument Factory under the trade name of a low-speed desktop centrifuge under the condition of a centrifugal force of 2000g for 45 minutes, the supernatant obtained is passed through the Shanghai Yanjin Filter Mesh Factory under the trade name of nylon yarn The 400-mesh gauze filter media sold is filtered to collect the filter cake;

[0086] B. Dissolve

[0087] According to the weight ratio of the filter cake to the aqueous sodium hydroxide solution of 1:3, the filter cake obtained in ste...

Embodiment 3

[0090] Example 3: Extraction of royal jelly extract of the present invention

[0091] The implementation steps of this embodiment are as follows

[0092] A. Extraction

[0093] According to the weight ratio of royal jelly to purified water 1:4, add the royal jelly sold by Jiangxi Wang's Bee Garden Co., Ltd. under the trade name royal jelly to purified water, mix well, and extract for 20h at a temperature of 38℃ and a stirring speed of 1000rpm , Using a centrifuge sold by Shanghai Anting Scientific Instrument Factory under the trade name of a low-speed desktop centrifuge under the condition of a centrifugal force of 6000g for 15 minutes, and the supernatant obtained is passed through the Shanghai Yanjin Filter Mesh Factory under the trade name of nylon yarn The sold 400 mesh stainless steel filter mesh filter media filter to collect filter cake;

[0094] B. Dissolve

[0095] According to the weight ratio of the filter cake to the aqueous sodium hydroxide solution of 1:4, the filter cak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com