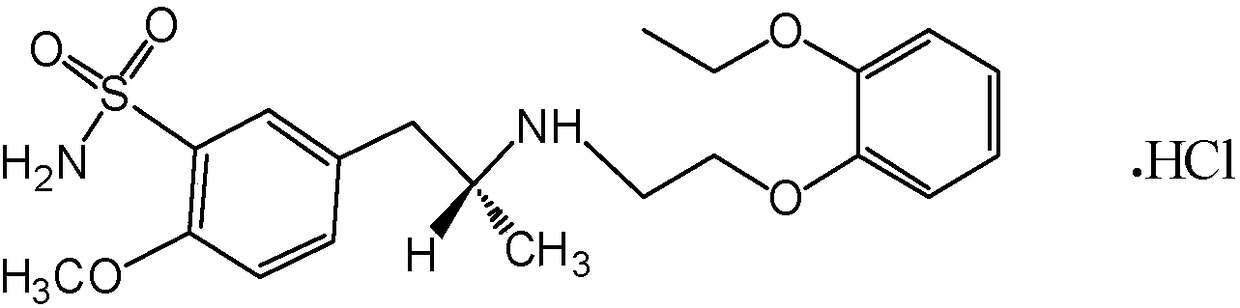

Tamsulosin orally disintegrating tablet composition with slow release performance

A technology for orally disintegrating tablets and tablets, applied to the preparation of tamsulosin hydrochloride orally disintegrating sustained-release tablet compositions with excellent pharmaceutical effects, and in the field of preparing tamsulosin medicaments, which can solve the problem of increasing the inoperability of the process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0229] Example 1: Preparation of Tamsulosin Hydrochloride Orally Disintegrating Tablets

[0230] (1) Dissolve 80 g of tamsulosin hydrochloride and 80 g of hydroxypropyl methylcellulose in 2000 g of purified water. Microcrystalline cellulose microparticles (Celphere102, Asahi Kasei, average particle diameter is about 120 μm, more than 95% particle diameter is in the range of 50-150 μm) 4000g is put into fluidized bed granulator, wraps with this solution with lateral spraying method Clothing to obtain tamsulosin hydrochloride particles.

[0231] The fluidized bed granulator above and in the context of the present invention is the WBF-60 fluidized bed granulator produced by Chongqing Yingge Granulation Coating Technology Co., Ltd. When using this fluidized bed granulator for granulation and / or coating, according to different materials, the spray speed can usually be controlled in the range of 10-120g / min, and the spray air pressure can usually be controlled in the range of 0.5-...

Embodiment 2

[0282] Example 2: Preparation of Tamsulosin Hydrochloride Orally Disintegrating Tablets

[0283] (1) Dissolve 80 g of tamsulosin hydrochloride and 80 g of hydroxypropyl methylcellulose in 2000 g of purified water. Put microcrystalline cellulose microparticles (Celphere102, Asahi Kasei, average particle diameter is about 160 μm, more than 95% particle diameter is in the scope of 100-250 μm) 4000g into fluidized bed granulator, use this solution to pack Clothing to obtain tamsulosin hydrochloride particles.

[0284] (2) Next, add 550 g of ethyl cellulose (ground and pass through a 200-mesh sieve) and 160 g of hydroxypropyl methylcellulose into 18,000 g of water, suspend the ethyl cellulose strongly and dissolve HPMC to obtain slow Release the coating suspension. Put 4000 g of tamsulosin hydrochloride particles into a fluidized bed granulator, and coat with the coating liquid by a side spraying method to obtain sustained-release pellets.

[0285] (3) Put 4000g of the slow-re...

Embodiment 3

[0298] Example 3: Preparation of Tamsulosin Hydrochloride Orally Disintegrating Tablets

[0299] (1) Dissolve 80 g of tamsulosin hydrochloride and 80 g of hydroxypropyl methylcellulose in 2000 g of purified water. Microcrystalline cellulose particles (Celphere102, Asahi Kasei, average particle diameter is about 80 μm, more than 95% of the particle diameter is in the range of 50-120 μm) 4000g is put into a fluidized bed granulator, and the solution is packaged with the side spray method. Clothing to obtain tamsulosin hydrochloride particles.

[0300] (2) Next, add 600 g of ethyl cellulose (ground and pass through a 200-mesh sieve) and 180 g of hydroxypropyl methylcellulose into 20,000 g of water, suspend the ethyl cellulose strongly and dissolve HPMC to obtain slow Release the coating suspension. Put 4000 g of tamsulosin hydrochloride particles into a fluidized bed granulator, and coat with the coating liquid by a side spraying method to obtain sustained-release pellets.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Sheet weight | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com