Preparation method of TC16 titanium alloy wire with superfine grain structures

A technology of TC16 and titanium alloy wire, which is applied in the field of titanium and titanium alloy material processing, can solve problems such as uneven compression deformation at room temperature, and achieve the effect of large-scale industrial production, high repeatability, and excellent room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

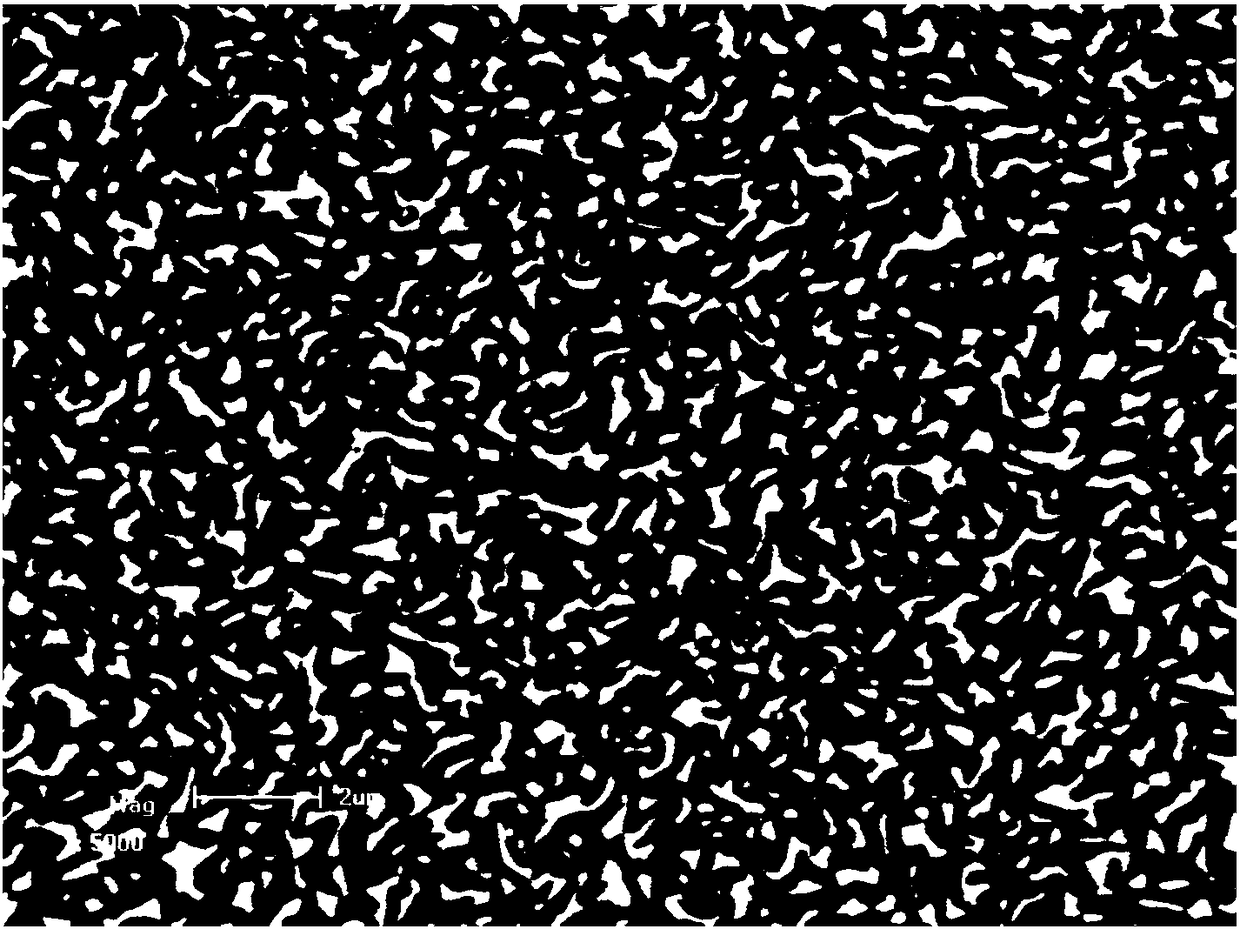

Embodiment 1

[0026] The TC16 titanium alloy rough billet with a diameter of 50mm was kept at 880°C for 2 hours, rolled to a diameter of 11.5mm, and then held at 720°C for 2 hours, then furnace cooled to 550°C, and then air-cooled. Peel the skin to φ10.7mm, then centerlessly grind to φ10.5mm, the surface roughness Ra is 6.3μm; then the polished rod is subjected to room temperature roller die drawing deformation, lubricated with metal processing oil, the drawing speed is 4m / min, the deformation amount of each pass It is about 14%, and the cumulative deformation is 88%, and a wire with a diameter of φ3.6mm is obtained. The grain size of the α phase and β phase in the wire was detected, and the average grain size of the two phases was measured to be about 0.3 μm. For the specific SEM microstructure photos, see figure 1 , obtained TC16 titanium alloy wire with ultra-fine grain structure.

Embodiment 2

[0028] The TC16 rough billet with a diameter of 36mm was kept at 900°C for 2 hours, rolled to a diameter of 9.5mm, then kept at 720°C for 2 hours, and then furnace cooled to 550°C and air-cooled. Peel the skin to φ8.7mm, then centerlessly grind to φ8.5mm, the surface roughness Ra is less than 6.3μm; then the polished rod is subjected to room temperature roller die drawing and deformation, lubricated with metal processing oil, the drawing speed is 5m / min, and the amount of deformation per pass It is about 15%, and the cumulative deformation is 78%, and a wire with a diameter of φ4mm is obtained. The grain size of α phase and β phase in the wire was detected, and the average grain size of the two phases was measured to be 0.4 μm. For the specific SEM microstructure photos, see figure 2 , obtained TC16 titanium alloy wire with ultra-fine grain structure.

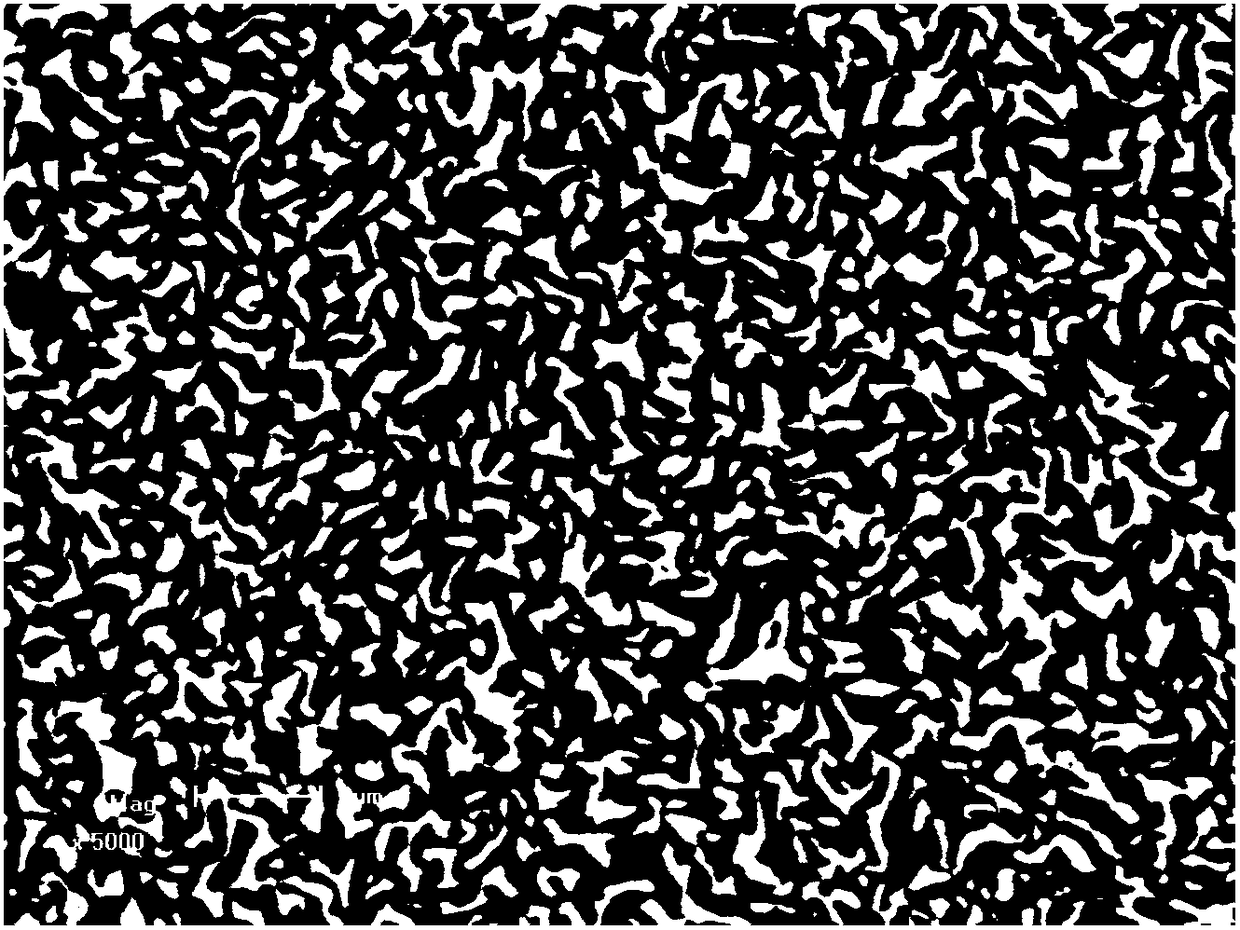

Embodiment 3

[0030] The TC16 rough billet with a diameter of 30mm was kept at 880°C for 2 hours, rolled to a diameter of 7.5mm, then kept at 760°C for 2 hours, and then furnace cooled to 550°C and air-cooled. Peel the skin to φ6.7mm, then centerlessly grind to φ6.5mm, the surface roughness Ra is less than 6.3μm; then the polished rod is subjected to room temperature roller die drawing deformation, lubricated with metal processing oil, the drawing speed is 8m / min, and the amount of deformation per pass It is about 18%, the accumulative deformation is 76%, and a wire with a diameter of φ3.2mm is obtained. The grain size of the α phase and β phase in the wire was detected, and the average grain size of the two phases was measured to be about 0.4 μm. For the specific SEM microstructure photos, see image 3 , obtained TC16 titanium alloy wire with ultra-fine grain structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com